Damping structure of automobile expansion valve

A shock-absorbing damping and expansion valve technology, which is applied in the field of automobile expansion valves to achieve good stability, stable opening and closing mechanism, and noise reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

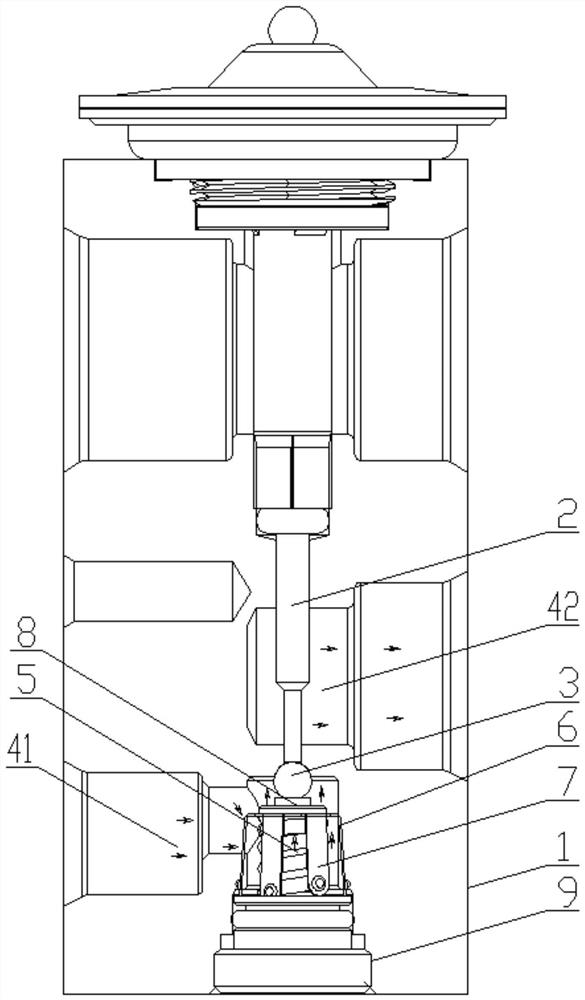

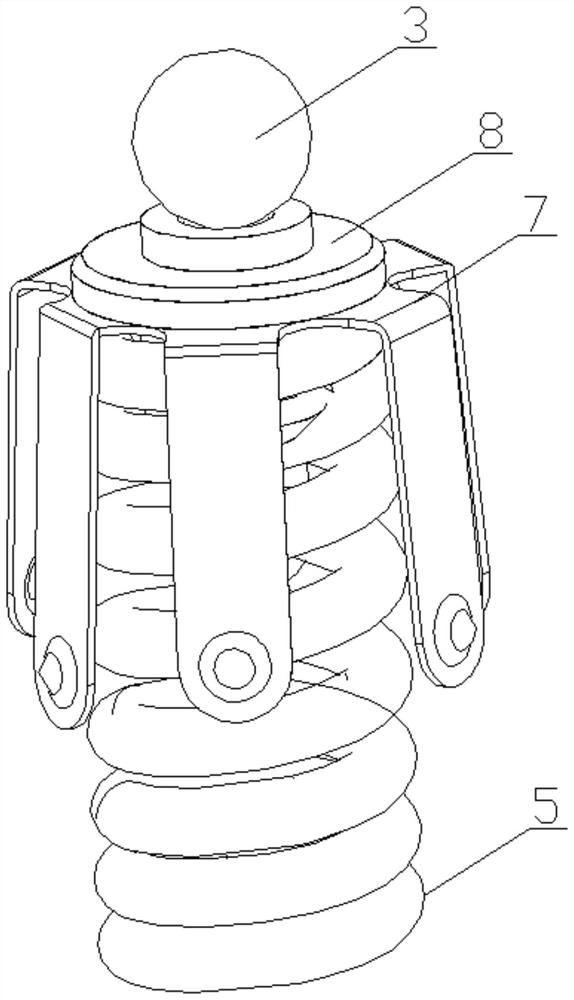

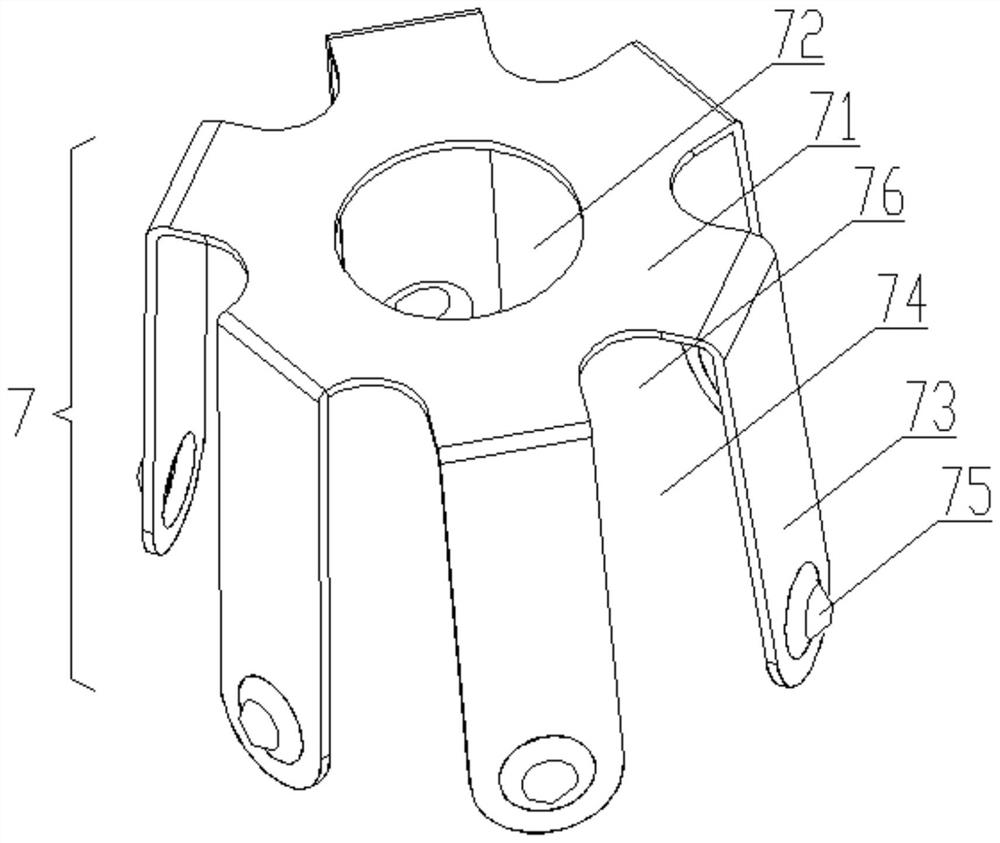

[0024] Such as Figure 1 to Figure 3 As shown, a shock-absorbing and damping structure of an automobile expansion valve includes a valve seat 1, a medium passage and an opening and closing mechanism, the inlet of the medium passage is connected to a compressor; the opening and closing mechanism includes a valve stem 2, and a ball 3 is connected to the lower end of the valve stem 2, and There is a chamber 6 below 3, and a spring 5 is arranged in the chamber 6, and the ball 3 is arranged in the medium channel; under the action of the driving force, when the valve stem 2 moves to drive the ball 3 to move downward to press the spring 5, The medium channel is opened to allow the medium to flow through; when the driving force is withdrawn, the spring 5 drives the ball 3 and the valve stem 2 to reset to close the medium channel; a damping part 7 is arranged on the periphery of the spring 5, and the damping part 7 is against the side of the chamber 6 wall. Among them, the media chann...

Embodiment 2

[0030] An automobile expansion valve shock-absorbing damping structure, referring to Embodiment 1, its main difference from Embodiment 1 is that the bottom end of the damping clip is fixed on the elastic element, that is, the base 9 is set as an axially expandable elastic element, With such a structure, during the downward movement of the ball 3, the damping clip and the elastic element will move downward synchronously, and the spring 5 will move downward under pressure.

Embodiment 3

[0032] A kind of automobile expansion valve shock-absorbing damping structure, refer to embodiment 1 and combine Figure 4 As shown, the main difference between it and Embodiment 1 is that no convex portion 75 is provided on the hem 73 of the damping clip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com