Dummy load testing device and automatic power adjusting method thereof

A test device and automatic adjustment technology, which is applied in the direction of power supply testing, electric power measurement through current/voltage, etc., can solve the problems of lack of intelligent control function, continuous adjustment of power accuracy, and high labor cost input, so as to reduce tedious and manpower input Cost, the effect of realizing intelligent control functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

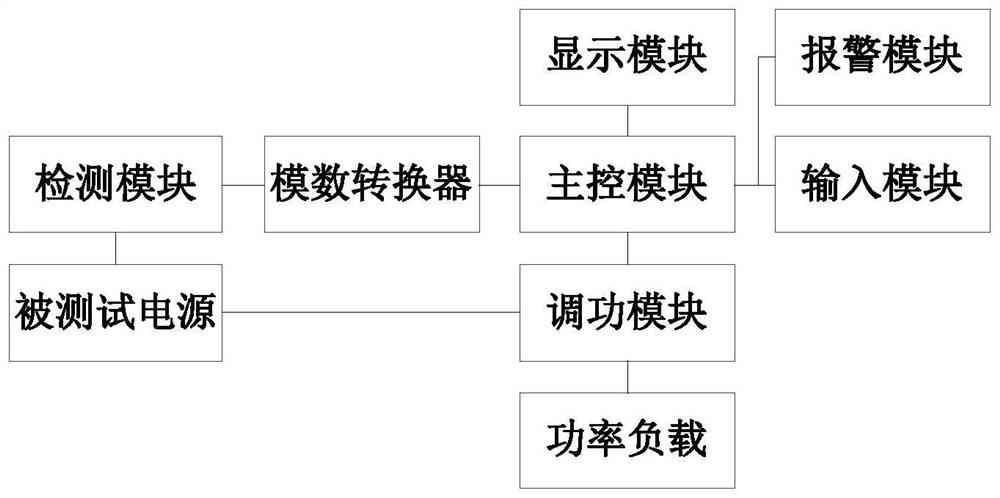

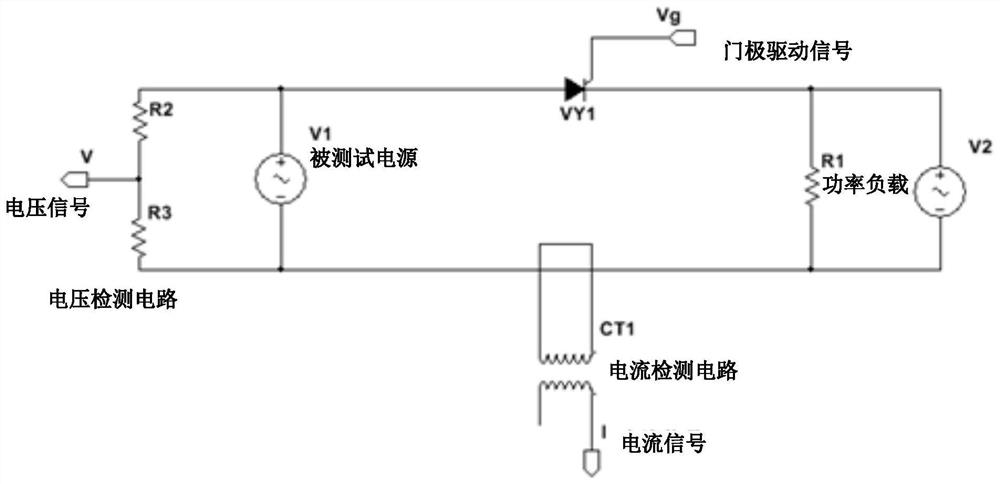

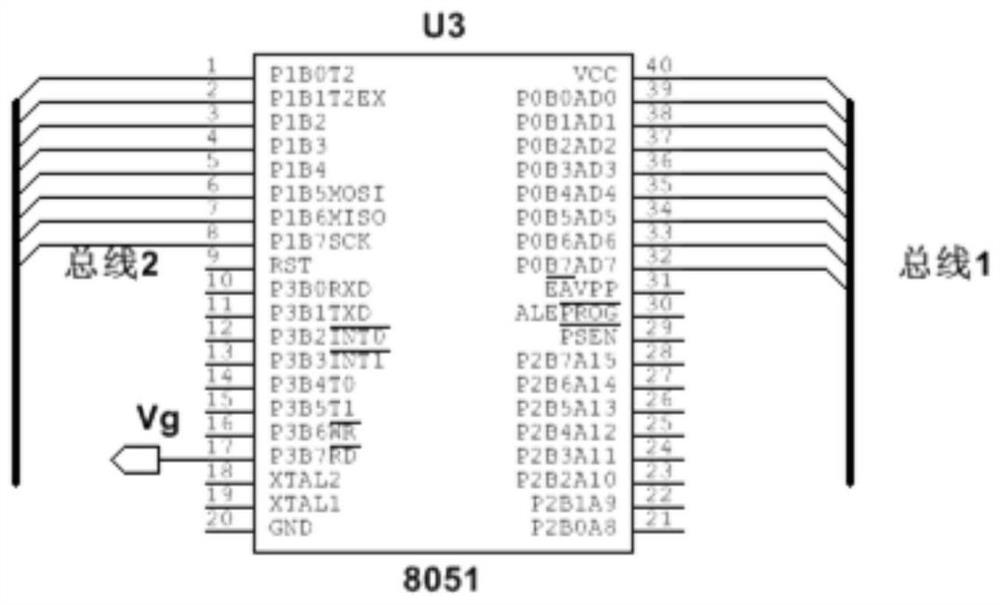

[0050] like figure 1 As shown, this embodiment provides a dummy load testing device, including a detection module, a main control module, a power regulation module and a power load, and the detection module, a main control module, a power regulation module and a power load are sequentially connected by communication, and the input of the detection module The communication terminal is connected to the output terminal of the power supply under test, and the input terminal of the power adjustment module is electrically connected to the output terminal of the power supply under test;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com