Radioactive waste resin recycling system and method

A technology of radioactive waste resin and waste resin, which is applied in the fields of radioactive purification and nuclear engineering, can solve the problems such as the method of taking out the waste resin from the tank without considering it, and achieve the effects of reducing the exposure dose of personnel, reliable retrieval and transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

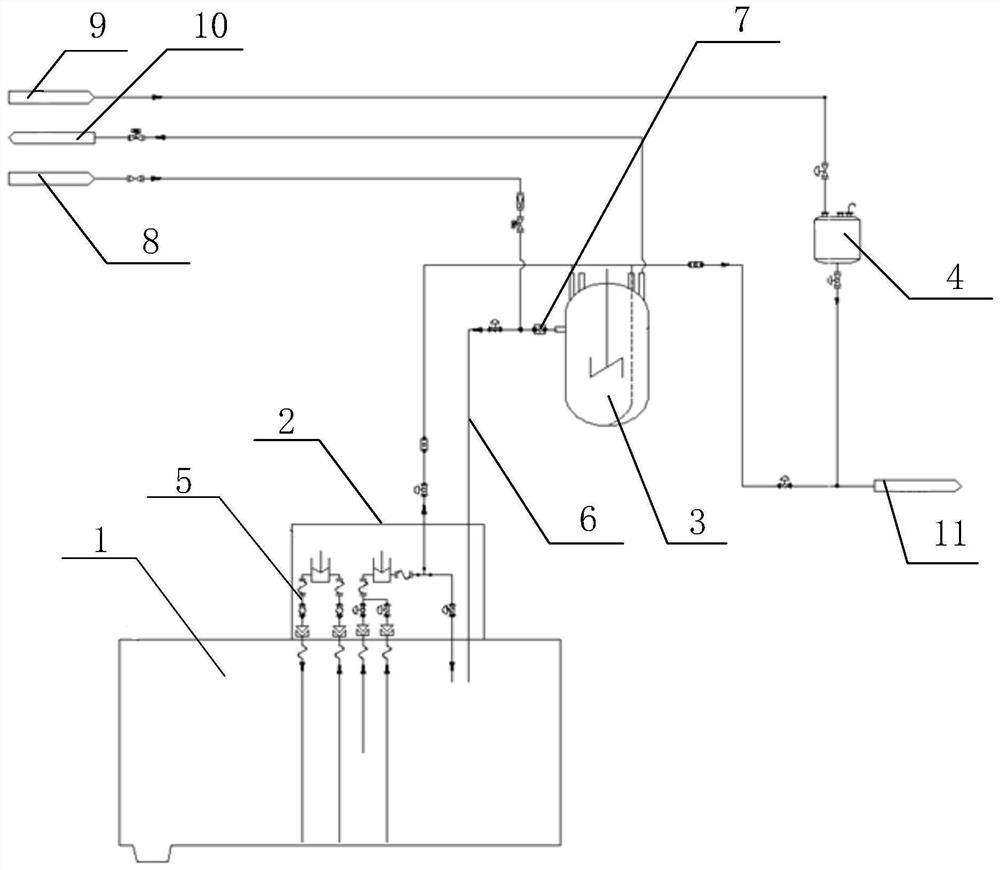

[0044] Such as figure 1 As shown, a radioactive waste resin retrieving system includes a retrieving device 2, a waste resin collection tank 3 and a control system;

[0045] The retrieval device 2 includes a stirring device 5 and a feeding pump, and the stirring device 5 is installed in the waste resin storage tank 1 through the top structure of the waste resin storage tank 1;

[0046] The waste resin collection tank 3 communicates with the waste resin storage tank 1 through a pipeline, and the feeding pump is installed on the pipeline between the waste resin storage tank 1 and the waste resin collection tank 3, and the waste resin collection tank 3 communicates with the waste resin storage tank 3 through the pipeline. The device 11 is connected;

[0047] The control system includes a controller and a plurality of liquid level sensors, liquid level sensors are installed in the waste resin storage tank 1 and the waste resin collection tank 3, and the liquid level sensor and the...

Embodiment 2

[0055] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and the waste resin collection tank 3 is provided with an overflow port, and the overflow port communicates with the waste resin storage tank 1 through the overflow pipe 6; A filter 7 is arranged near the overflow port; an air compressor 8 is also included, and the air compressor 8 is connected to the overflow pipe 6 through a pipeline, and the connection position between the pipeline and the overflow pipe 6 is arranged at the rear end of the filter 7 ; The overflow port is set on the upper part of the waste resin collection tank 3 .

[0056] The retrieval method of the present embodiment comprises the following steps:

[0057] S1, connecting the retrieval system with the waste resin storage tank 1;

[0058] S2. Start the retrieving device 2 to stir the waste resin in the waste resin storage tank 1 to make the waste resin reach a suspension state;

[0059] S3, start the feeding pump of the retrieval...

Embodiment 3

[0065] Such as figure 1 As shown, this embodiment is based on Embodiment 1, and also includes a cleaning water tank 4, which is used to store desalinated water, and the cleaning water tank 4 is connected with the pipeline of the retrieval system; The brine storage tank 9 is communicated.

[0066] In this embodiment, the desalted water in the cleaning water tank 4 is used to clean the delivery pipeline to prevent the waste resin from clogging the delivery pipeline.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com