Semiconductor wafer surface cleaning and safe storage protection box

A surface cleaning and protection box technology, which is applied in semiconductor/solid-state device manufacturing, transportation and packaging, conveyor objects, etc., can solve the problems of damaged wafer circuit, wafer damage, loss, etc., and achieve the effect of reducing vibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

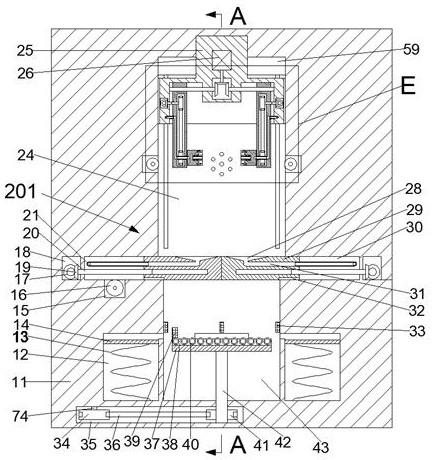

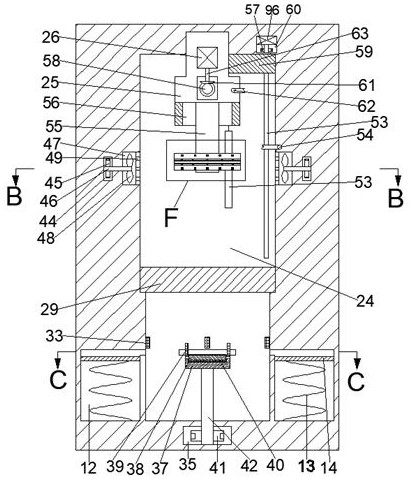

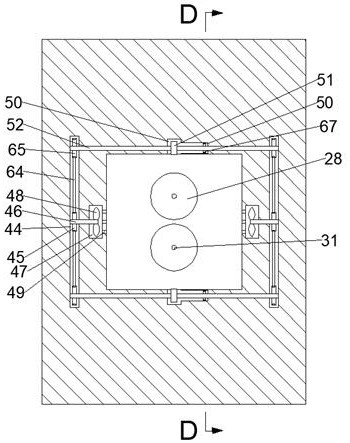

[0025] Combine below Figure 1-9 The present invention is described in detail, wherein, for the convenience of description, the orientations mentioned below are defined as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are the same.

[0026]A semiconductor wafer surface cleaning and safe storage protection box according to the present invention includes a box body 11, a lifting cavity 24 is arranged inside the box body 11, and a clip is provided for sliding up and down between the left and right walls of the lifting cavity 24. Holding block 25, the clamping block 25 is provided with a clamping plate cavity 56 with an opening downward, and the left and right walls of the clamping plate cavity 56 slide left and right and are symmetrically provided with a clamping plate 55. The plate 55 is rotatably connected to one end face and is provided with a rotating block 23. The rotating block 23 is provided with a clamping ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com