Power cable maintenance equipment

A power cable and equipment technology, applied in the field of power cable maintenance equipment, can solve the problems of low reliability of work efficiency, inability to break wires and wrap insulating tape, and lower reliability of work efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

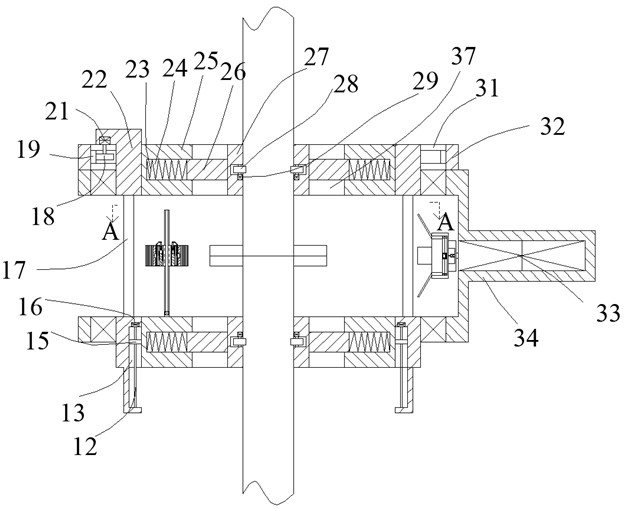

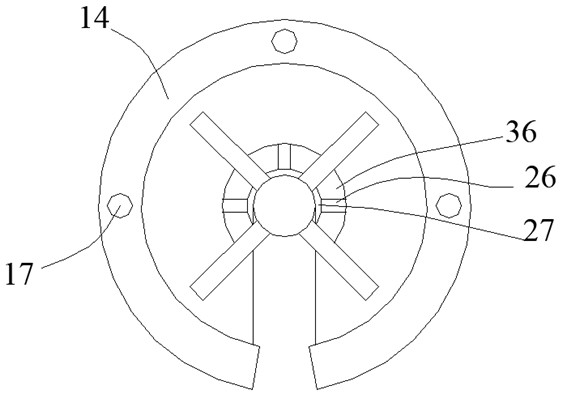

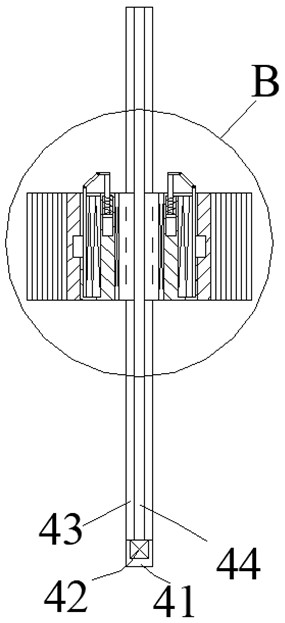

[0023]Such asFigure 1-Figure 6As shown, the present invention will be described in detail. For the convenience of description, the following directions are specified as follows:figure 1 The projection relationship is the same in the up, down, left, and right directions. The power cable maintenance equipment of the present invention includes a circular moving block 34. The top of the circular moving block 34 is provided with a side ring block 32, and the side ring block 32 is provided with a through The inside penetrates the inner cavity 31, the annular moving block 34 is provided with symmetrical side fixed support blocks 22 rotating up and down, and a number of intermediate fixed rods 17 are arranged between the side fixed support blocks 22, and the side fixed supports at the top The block 22 is provided with an internal rotation motor 21, the lower side of the internal rotation motor 21 is dynamically connected with a bottom connecting gear 18, and the bottom connecting gear 18 me...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap