Exhaust gas purifying catalyst and method for producing the same

A technology for exhaust purification and manufacturing methods, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., to achieve high durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

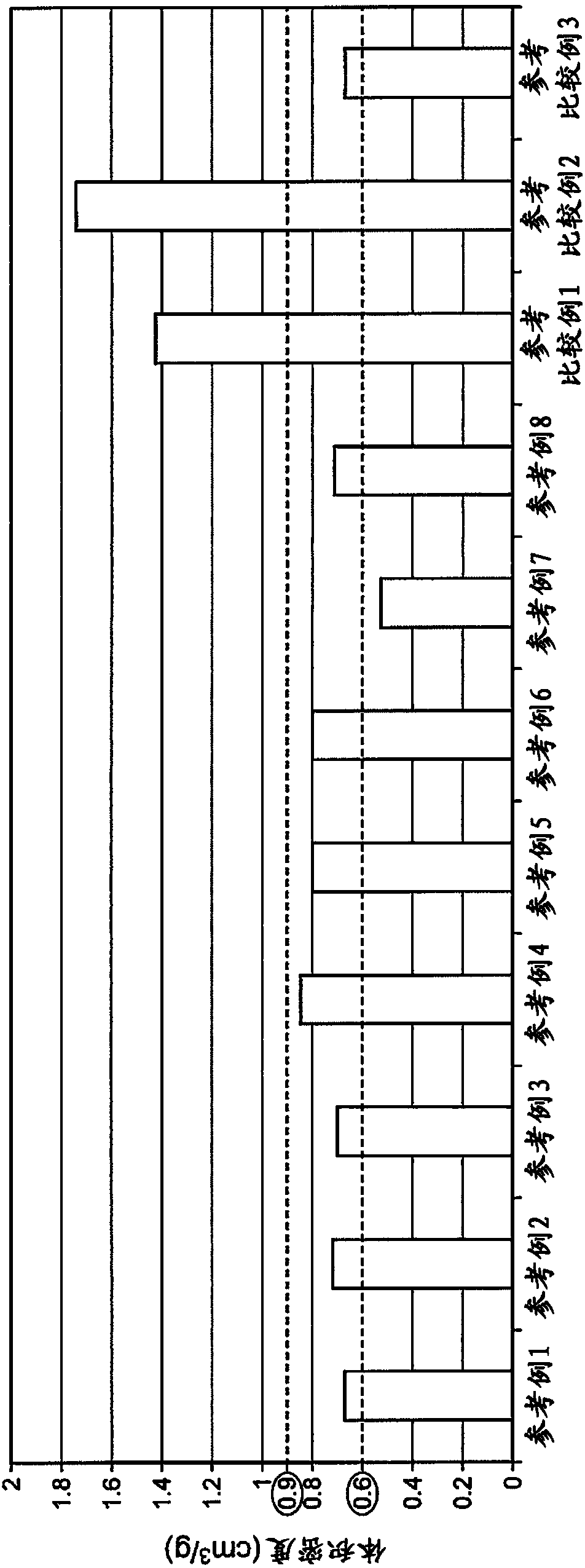

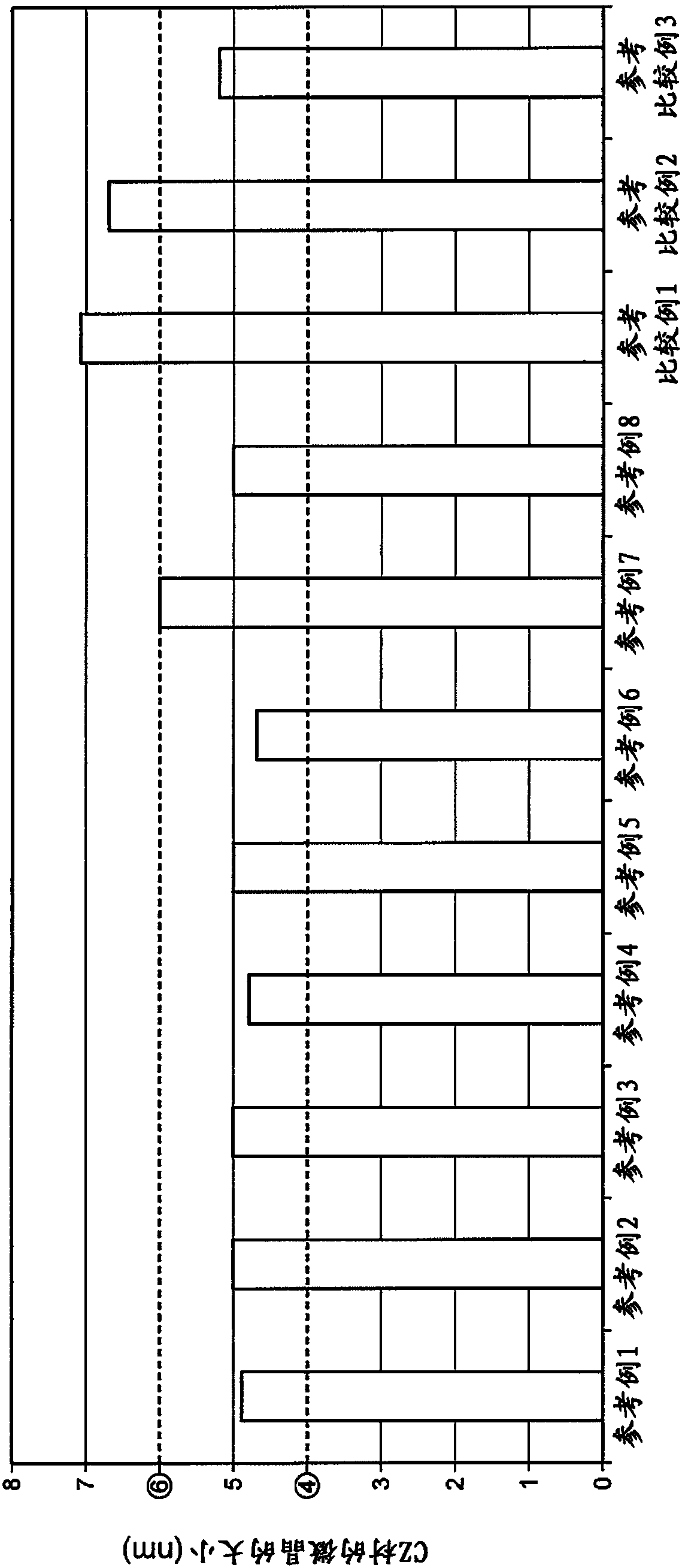

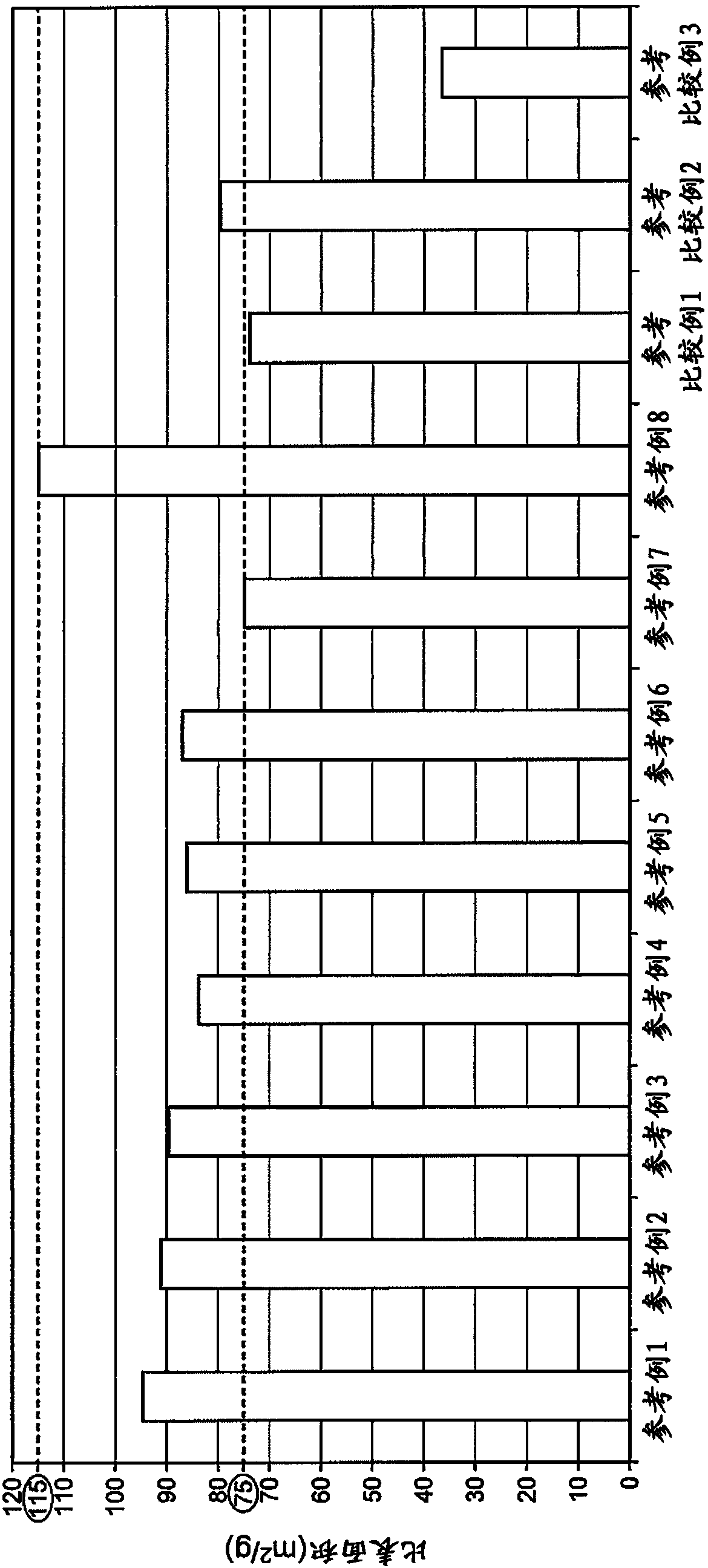

reference example 1

[0073] In distilled water 400cc(cm 3 ) dissolved 47.1g of Ce(NO 3 ) 3 ·6H 2 O, 52.1g of ZrO(NO 3 ) 2 2H 2 O, stirred at 85°C, and slowly added 80.1 g of Al(OC) while confirming its dissolution 3 h 7 ) 3 , After dissolving, use a rotary evaporator to completely remove water at 90°C, and then calcinate at 900°C for 5 hours to produce Al 2 o 3 :CeO 2 :ZrO 2 =Composite oxide of 32:30:38.

reference example 2

[0075]The conditions of Reference Example 1 were the same as those of Reference Example 1 except that the distilled water in Reference Example 1 was changed to 800 cc.

reference example 3

[0077] The conditions of Reference Example 1 were the same as those of Reference Example 1 except that the distilled water in Reference Example 1 was changed to 1200 cc.

[0078]

[0079] Dissolving Al(OC in Reference Example 1 3 h 7 ) 3 The conditions were the same as in Reference Example 1 except that 8 cc of 60% nitric acid was added thereafter.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com