Biomass material bag-opening equipment

A technology of biomass materials and equipment, applied in the directions of unpacking, packaging, loading/unloading of objects, etc., which can solve the problems of reduced efficiency and reduced equipment reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

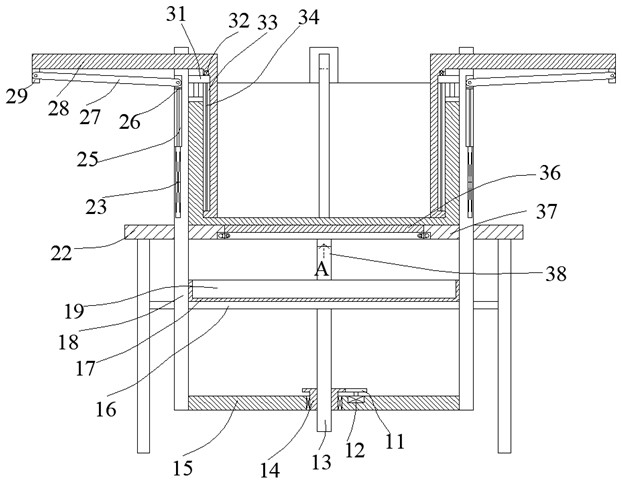

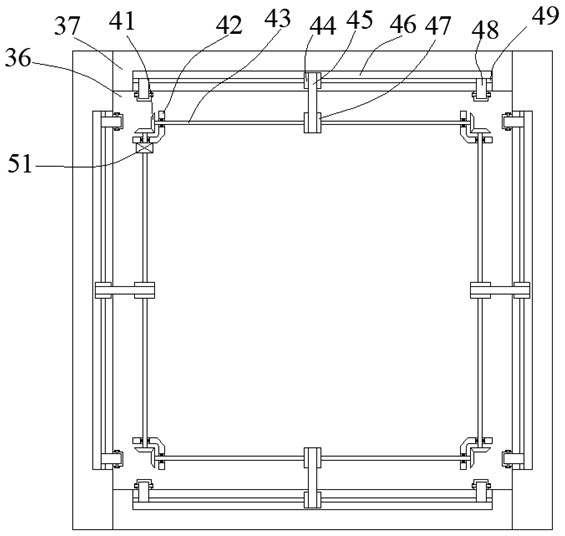

[0021] Such as Figure 1-Figure 2 As shown, the present invention is described in detail. For the convenience of description, the orientations mentioned below are now stipulated as follows: figure 1 The up, down, left, right, front and back directions of the projection relationship itself are consistent. The biomass material bag opening equipment of the present invention includes a top plate 22, a fixed plate 16 is fixed between the top plates 22, and a bottom is fixed on the upper end surface of the fixed plate 16. Fixed bracket 38, the upper end surface of the bottom fixed bracket 38 is fixed with a middle hanging plate 36, and the outer side of the middle hanging plate 36 is provided with a turning and exporting device that can be flipped in linkage so as to lead the biomass material downward. 16 is provided with a receiving device for receiving biomass materials, and a plurality of sliding fitting rods 18 are arranged slidingly inside the top plate 22, and a device is prov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com