High-impact-resistant motor and installation method thereof

An impact motor, anti-high technology, applied in the direction of electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of not meeting high impact requirements, restrictions on imported motors, etc., and achieve the effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Reference will now be made in detail to the exemplary embodiments, examples of which are illustrated in the accompanying drawings. The "first" or "second" etc. only mean to distinguish similar components or devices, and do not represent limitations.

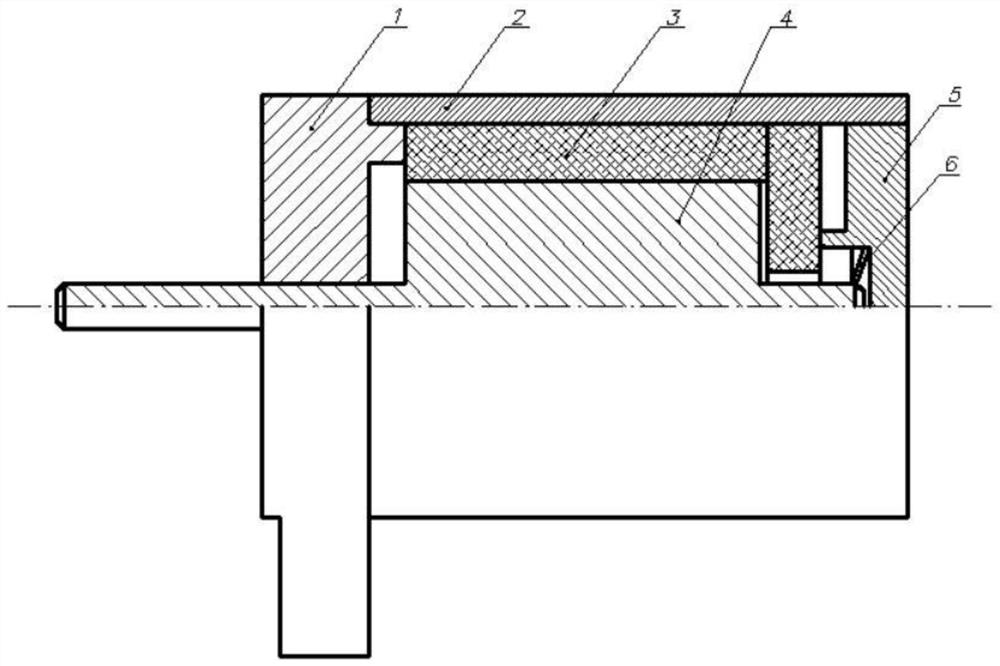

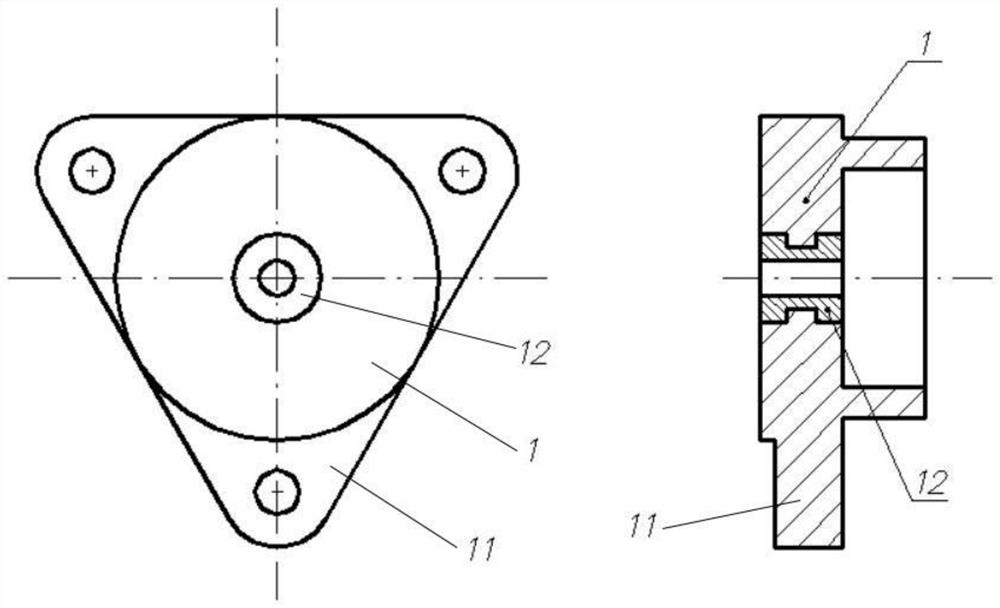

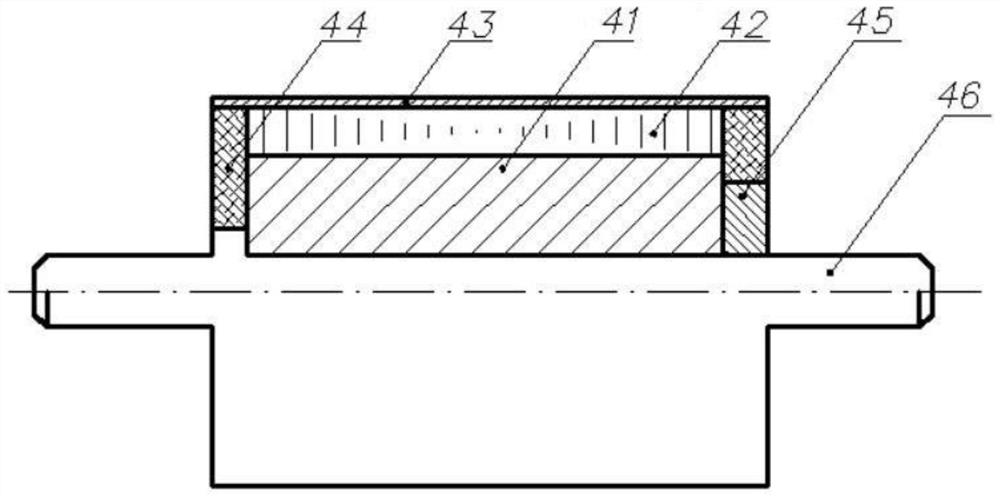

[0028] Such as Figure 1-3 As shown, the anti-high impact motor of the embodiment of the present invention includes a front end cover 1, a rear end cover 5 and a rotor 4, a front bearing 11 is installed in the front end cover 1, and a rear bearing is installed in the rear end cover 5; the rotor 4 includes a soft Magnetic sleeve 41, magnetic steel 42, stainless steel sleeve 43 and shaft 46, the soft magnetic sleeve 41 is sleeved on the outer circumference of the shaft 46, the magnetic steel 42 is sleeved on the outer circumference of the soft magnetic sleeve 41, the stainless steel sleeve 43 is sleeved on the magnetic steel 42 Outside; the front end of the shaft of the rotor 4 is rotatably connected to the front bearing 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com