Petroleum pipe cleaning device

A technology for cleaning devices and oil pipelines, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., and can solve tedious and time-consuming problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

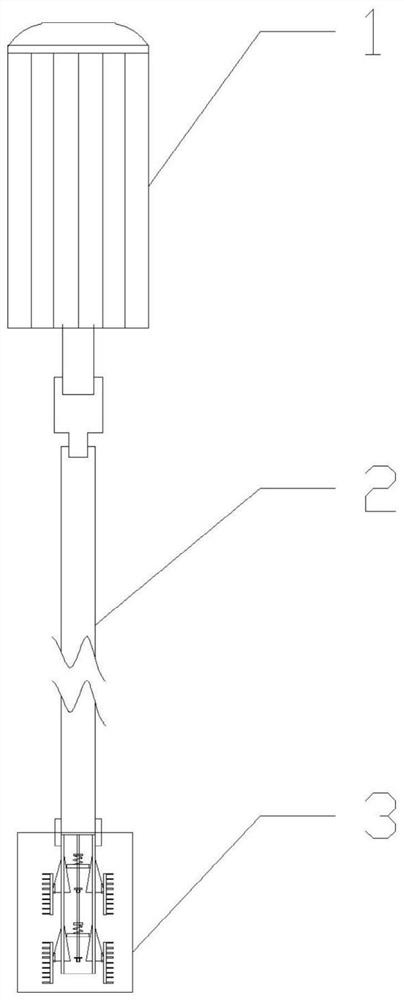

[0018] An oil pipeline cleaning device, such as figure 1 , including a motor 1 and a rotating rod 2, one end of the rotating rod 2 is connected with the rotor of the motor 1, and the other end is connected with the cleaning structure 3.

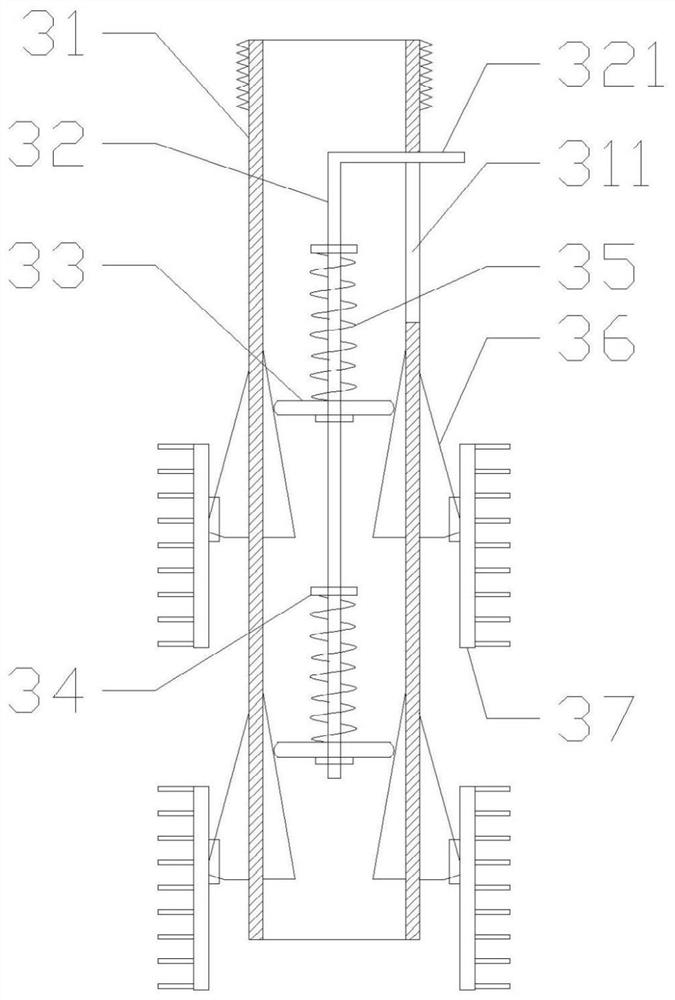

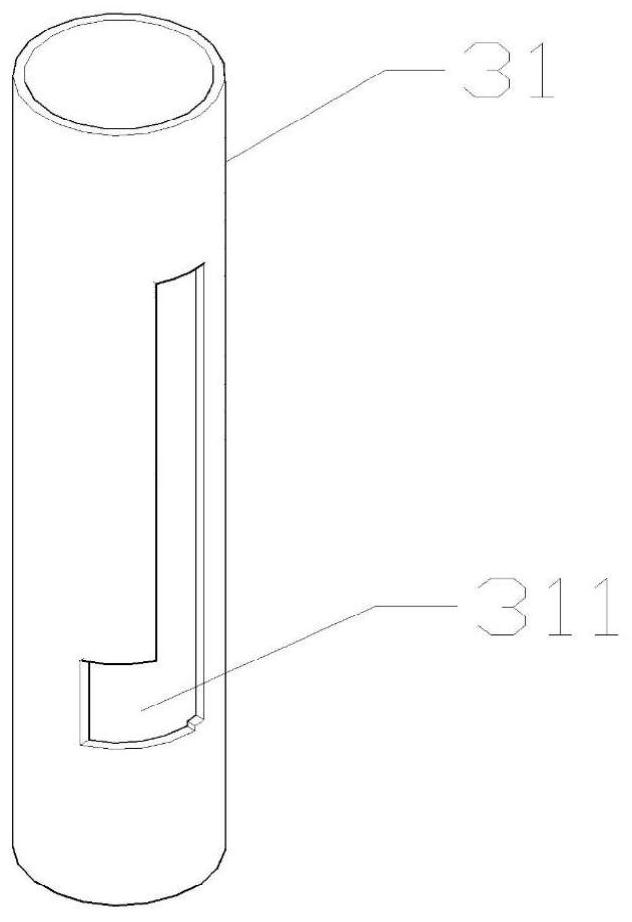

[0019] Such as figure 2 with image 3 , the cleaning structure includes a cylinder body 31 and two cleaning assemblies, each cleaning assembly includes a push rod 32, a disc 33, a stop ring 34, an elastic element 35, a trapezoidal block 36, and a cleaning head 37; the push rod 32 is located in the barrel In the body 31, the disc 33 is movably socketed on the push rod 32, and the limit ring 34 is arranged on the push rod 32, above and below the disc 33, so that the disc 33 can only move within a certain range along the push rod 32. Longitudinal movement inside, an elastic element 35 is set between the disc 34 and the stop ring 34 above it; the trapezoidal block 36 runs through the side wall of the cylinder 31 and faces the position of the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com