A kind of automatic cutting method of aluminum alloy automatic cutting sawing machine

A cutting method and aluminum alloy technology, applied in the field of machinery, can solve the problems of not having the function of adjusting and fixing plates of different specifications, not being able to adapt to the cutting operation of plates of specifications, and increasing the extra consumption of power sources, so as to save power source consumption and provide work. Efficiency, time-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

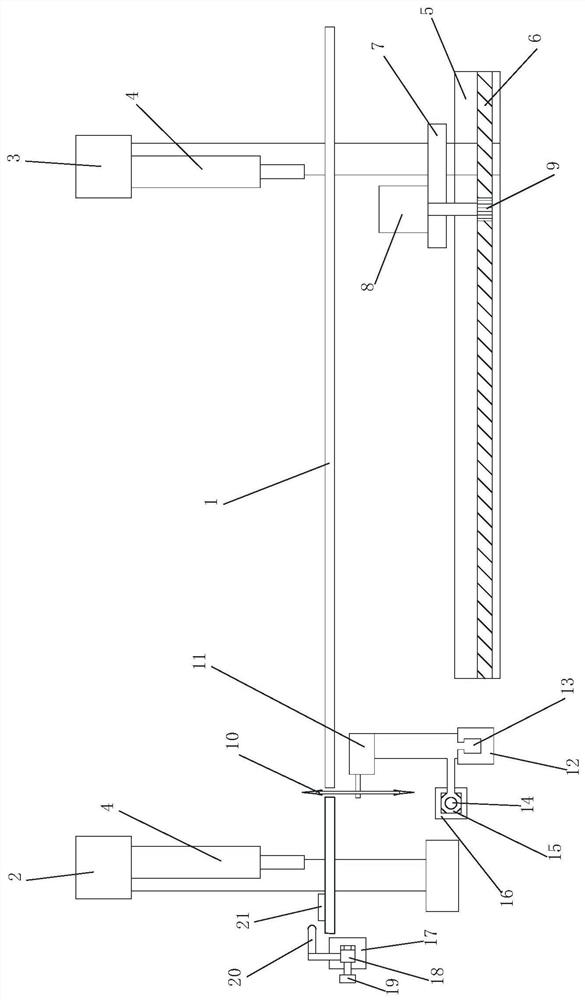

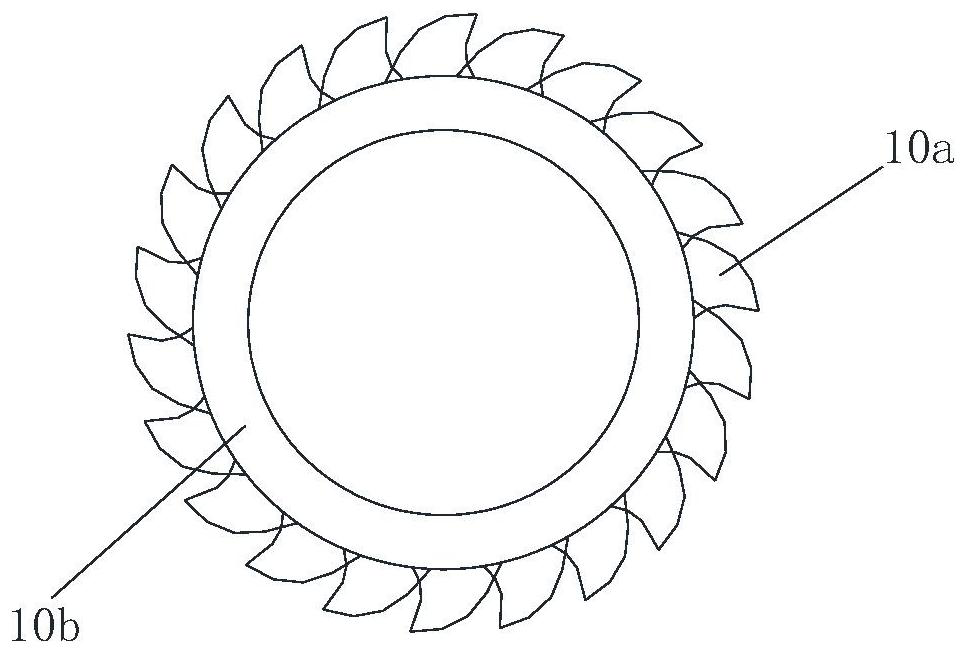

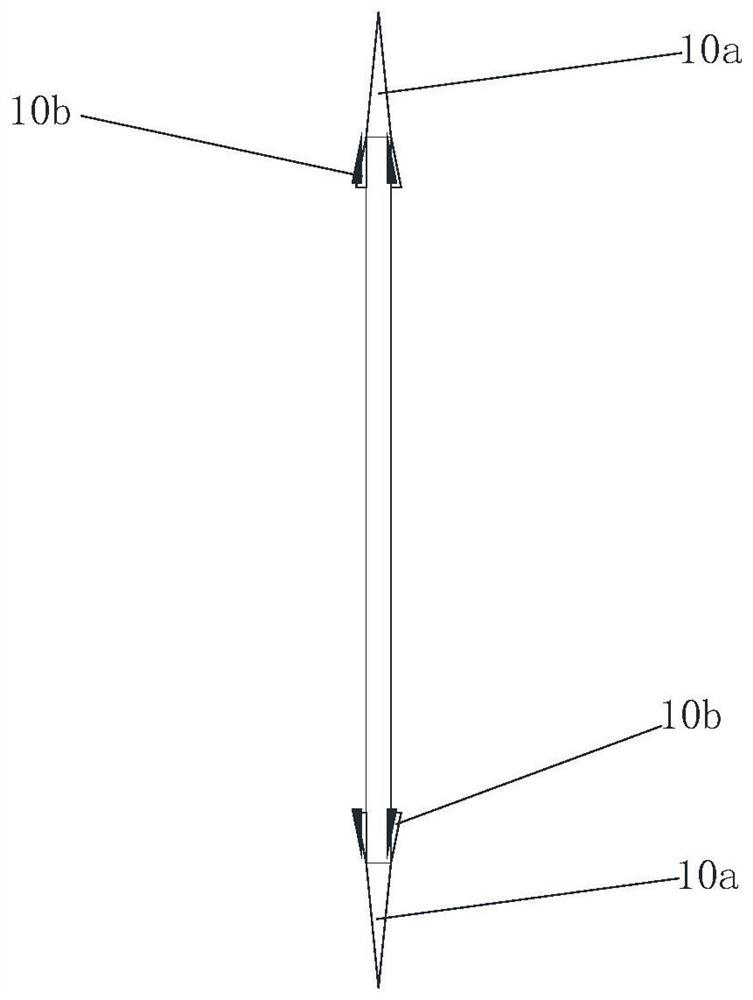

[0028] Such as Figure 1 to Figure 3 As shown, the aluminum alloy automatic cutting sawing machine includes a controller and a frame. A support platform 1 is set on the frame, a positioning and clamping mechanism 2 is set on one edge of the support platform 1, and a moving clamp is set on the other edge. The clamping mechanism 3, the positioning clamping mechanism 2 and the mobile clamping mechanism 3 are arranged in parallel, the bottom of the mobile clamping mechanism 3 is provided with a clamping and sliding mechanism, and the sliding direction of the clamping and sliding mechanism is clamped with the moving clamping mechanism 3 The fixed line is perpendicular to each other, and a cutting and sliding mechanism is set under the supporting platform 1. The cutting and sliding mechanism is parallel to the positioning and cla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com