Multi-source fluorine-containing waste residue glass ceramic solidified body as well as preparation method and application thereof

A technology of glass-ceramic and solidified body, which is applied in the field of multi-source fluorine-containing waste residue glass-ceramic solidified body and its preparation, can solve the problems of difficult to handle, difficult to block the penetration of fluorine element for a long time, fluoride pollution to the environment, etc., and achieve stable solidification. Good performance, realizing the full quantitative utilization of components, and the effect of large curing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

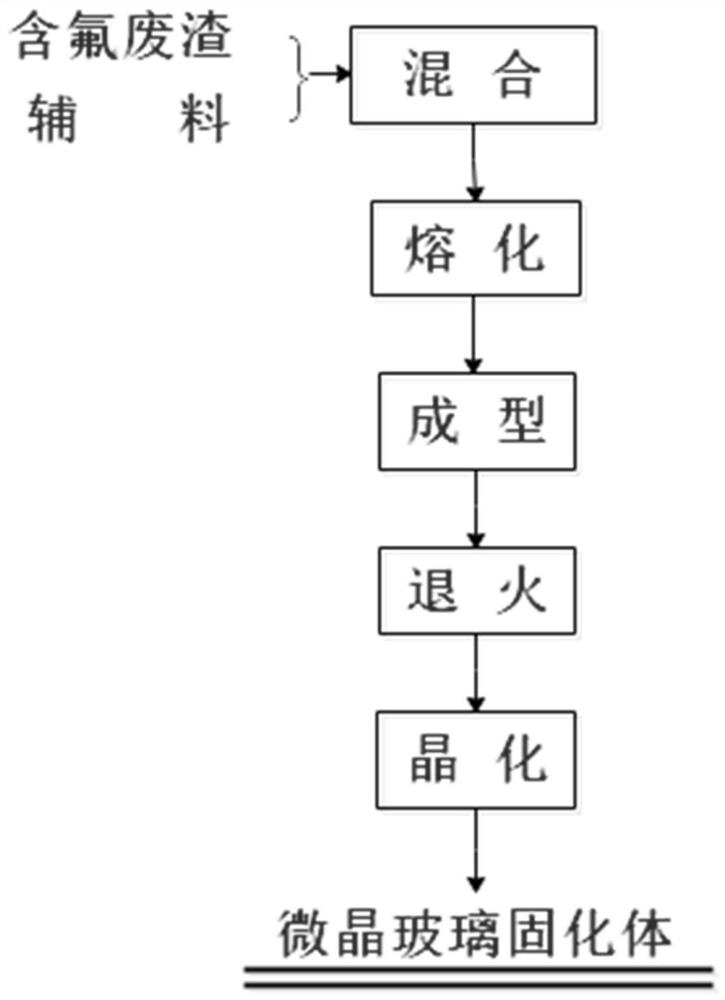

[0074] The preparation method comprises the following steps:

[0075] The fluorine-containing waste slag is mixed with auxiliary materials, melted, and then formed, annealed, and crystallized in sequence to obtain a solidified glass-ceramic body.

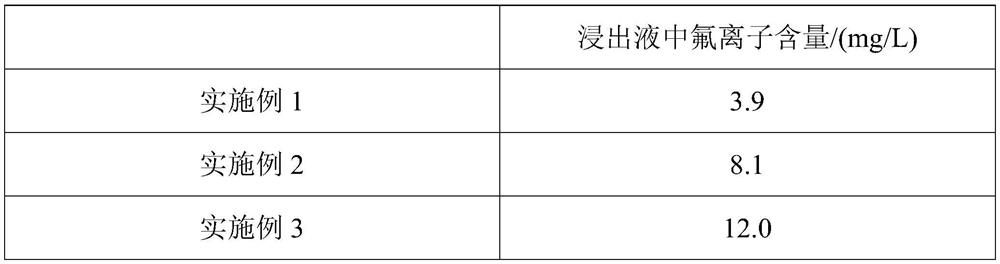

Embodiment 1

[0078] This embodiment provides a glass-ceramic block, the raw materials of the glass-ceramic block include 81.2kg electrolytic aluminum ash, 20.0kg Na 2 SiF 6 , 142.0kg CaCO 3 , 22.5kg MgO, 100.0kg Fe 2 o 3 and 310.0kg SiO 2 , 1.0kgNa 2 CO 3 ;

[0079] The composition of the electrolytic aluminum ash is by weight percentage: 52.7% Al 2 o 3 , 13.0% MnO 2 , 8.0% MgO, 12.0% SiO 2 , 7.0%K 2 O, 4.3% CaF 2 , 3.0% CaO;

[0080] The main crystal phase of the glass-ceramic block is a diopside crystal phase; the secondary crystal phase of the glass-ceramic solidified body is a pyroxene crystal phase.

Embodiment 2

[0082] This embodiment provides a glass-ceramic plate, the raw material of the glass-ceramic plate includes 25.0kg graphite fluorine-containing sludge, 23.5kg Na 2 CO 3 , 13.5kg CaCO 3 、9.3kgK 2 CO 3 , 1.0kg MgO and 112.5kg SiO 2 ;

[0083] The composition of the graphite fluorine-containing sludge is by weight percentage: 78.0% CaF 2 , 9.5% CaCO 3 and 12.5% CaSO 4 ;

[0084] The main crystal phase of the glass-ceramic plate is xonotlite crystal phase; the secondary crystal phase of the solidified glass-ceramic body is diopside crystal phase and quartz crystal phase.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap