A method for preparing recycled aggregate from Bayer process red mud

A Bayer process red mud and recycled aggregate technology, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problem that industrial application cannot be truly realized, red mud dealkalization pretreatment costs are high, and there is no solution High alkalinity of red mud and other problems, achieve good solidification and stability, reduce energy consumption, and protect mineral resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

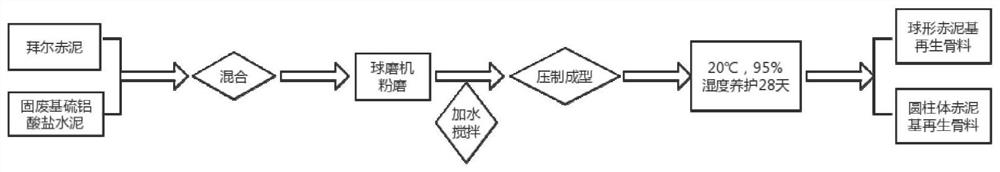

Method used

Image

Examples

preparation example Construction

[0048] In the preparation process of solid waste-based sulfoaluminate cement and red mud-based aggregate, the same batch of red mud, desulfurized gypsum, and carbide slag are used as raw materials.

[0049] The preparation process of solid waste-based sulphoaluminate cement:

[0050] Table 1. The chemical composition of raw materials for the preparation of solid waste-based sulphoaluminate cement

[0051]

[0052]

[0053] Solid waste-based sulphoaluminate cement uses red mud, desulfurized gypsum, aluminum ash, and calcium carbide slag. According to the raw material ratio shown in Table 2, it is ground-mixed-calcined in a rotary kiln at 1250°C and held for 45 minutes. -Solid waste-based sulphoaluminate cement clinker-Solid waste-based sulphoaluminate cement, to realize the preparation of solid waste-based sulphoaluminate cement.

[0054] Table 2. Raw material ratio for preparing solid waste-based sulphoaluminate cement

[0055] red mud Desulfurization gypsu...

Embodiment 1

[0057] The raw materials were weighed according to the following percentages by weight: 30% solid waste-based sulphoaluminate cement, 60% Bayer process red mud, 5% desulfurized gypsum, and 5% carbide slag.

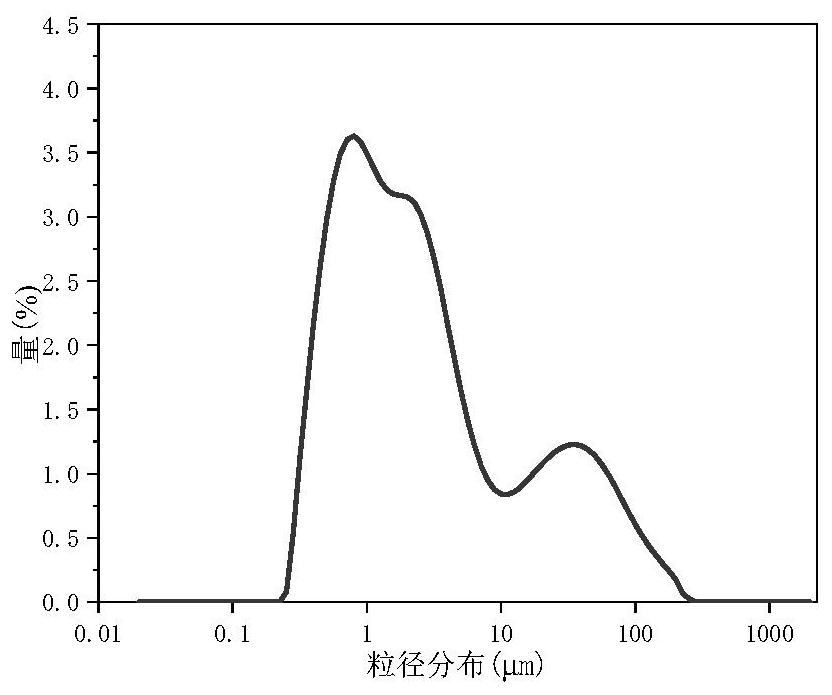

[0058] Dry the Bayer red mud at 105°C, add solid waste-based sulphoaluminate cement according to the above ratio and grind it evenly in a ball mill, control the fineness by controlling the grinding time, and break the red mud by means of mechanical grinding Middle Al 2 o 3 and SiO 2 The Al-O chemical bond and Si-O chemical bond in the mixture can stimulate the potential activity and improve the performance of the red mud-based aggregate. The particle size range of the prepared active mixed powder is more than 200 mesh (0.075mm).

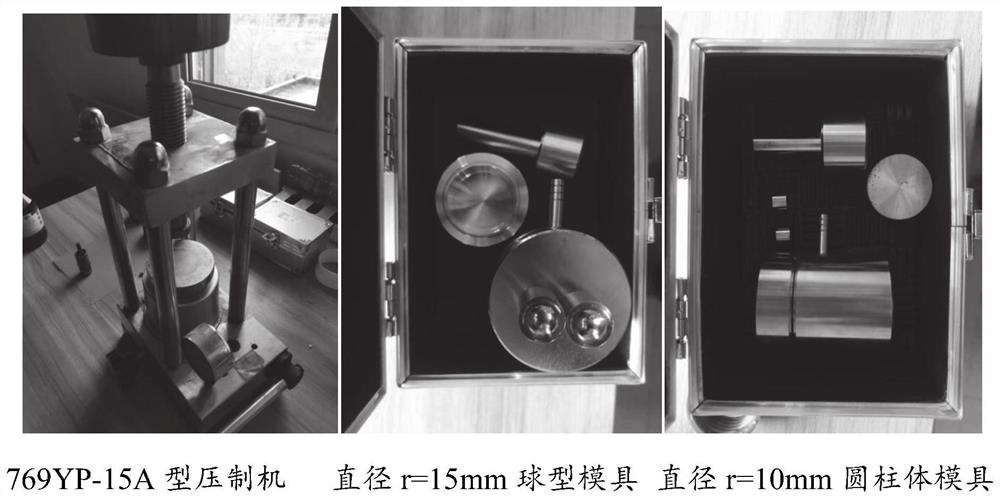

[0059] Then mix and grind the above mixed powder with 5% desulfurized gypsum and 5% carbide slag for 5 minutes, and add water equivalent to 8% of the total mass of solid waste raw materials. Two kinds of molds with a diameter of r = 15mm and a...

Embodiment 2

[0061] The raw materials were weighed according to the following percentages by weight: 25% solid waste-based sulphoaluminate cement, 65% Bayer process red mud, 5% desulfurized gypsum, and 5% carbide slag.

[0062] Dry the Bayer red mud at 105°C, add solid waste-based sulphoaluminate cement according to the above ratio and grind it evenly in a ball mill, control the fineness by controlling the grinding time, and break the red mud by means of mechanical grinding Middle Al 2 o 3 and SiO 2 The Al-O chemical bond and Si-O chemical bond in the mixture can stimulate the potential activity and improve the performance of the red mud-based aggregate. The particle size range of the prepared active mixed powder is above 200 mesh (0.075mm).

[0063] Then mix and grind the above mixed powder with 5% desulfurized gypsum and 5% carbide slag for 5 minutes, and add water equivalent to 8% of the total mass of solid waste raw materials. Two kinds of molds with a diameter of r = 15mm and a cyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap