Low-viscosity flowing type high-thermal-conductivity flame-retardant packaging material and preparation method thereof

A packaging material, flow-type technology, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems of lack of fluidity, poor flame retardant performance, high consistency, and achieve good curing stability. , the effect of good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

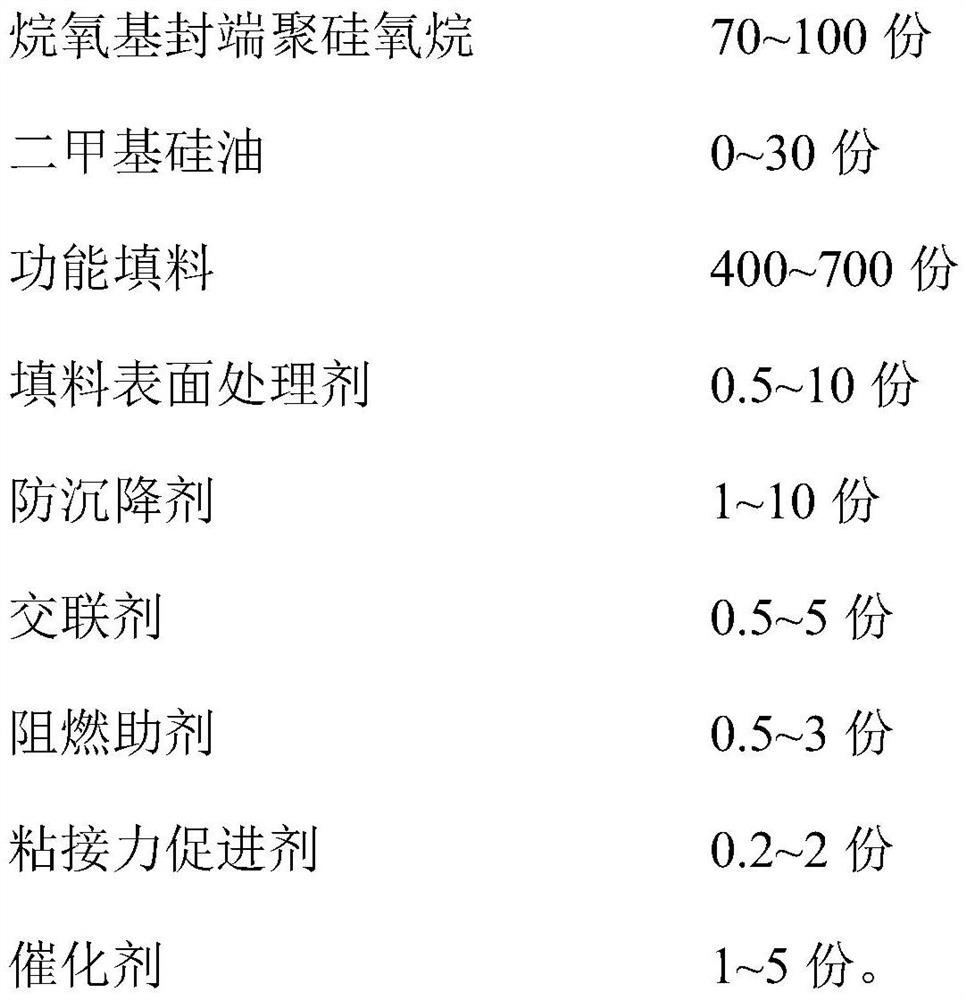

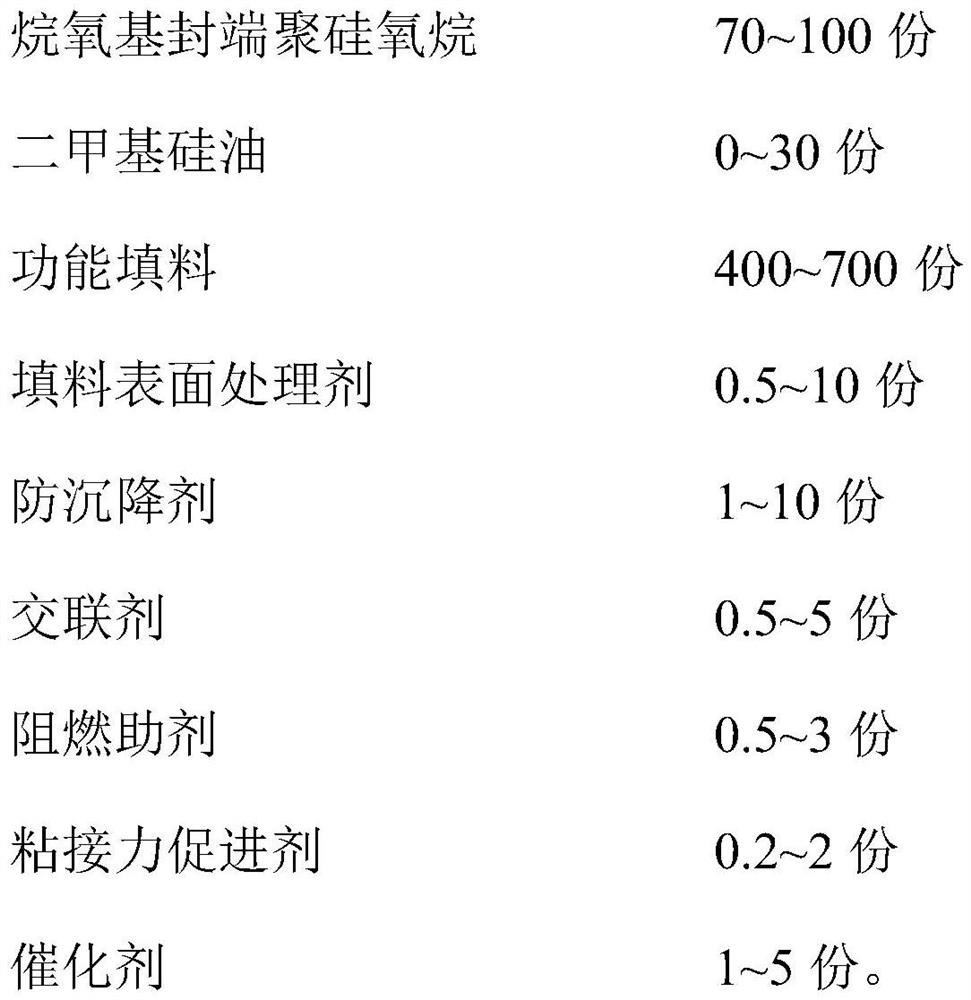

Method used

Image

Examples

Embodiment 1

[0059] (1) React 1.5 parts of γ-aminopropyltriethoxysilane with γ-glycidyloxypropyltrimethoxysilane (molar ratio is 1:2), 3.5 parts of methyltrimethoxysilane and 1.9 parts of acetyl The ethyl acetate titanium complex was pre-mixed uniformly in a clean and airtight container, and then the mixture was reacted at 45 degrees for 90 minutes.

[0060] (2) Add 632 parts of the above-mentioned 1# base glue and 20 parts of the above-mentioned bistrimethoxy-terminated polysiloxane with a viscosity of 1020 mPa.s into the planetary stirring tank, and stir for 30 minutes at a speed of 40 r / min.

[0061] (3) Add 3.5 parts of fumed silica with a specific surface area of 150m2 / g and surface treated with silazane, and stir for 30 minutes at a speed of 45r / min.

[0062] (4) Add 7.7 parts of the mixed reactants in the above-mentioned first step (1), 0.7 parts of divinyltetramethyldisiloxane platinum complex with a platinum content of 3000ppm, and depressurize the planetary stirring tank to -0....

Embodiment 2

[0065] (1) With embodiment 1.

[0066] (2) Add 632 parts of the above-mentioned 2# base glue and 20 parts of the above-mentioned bistrimethoxy-terminated polysiloxane with a viscosity of 1020 mPa.s into the planetary stirring tank, and stir for 30 minutes at a speed of 40 r / min.

[0067] (3) Add 2.5 parts of fumed silica with a specific surface area of 150m2 / g and surface treated with silazane, and stir for 30 minutes at a speed of 45r / min.

[0068] (4) (5) with embodiment 1.

Embodiment 3

[0070] (1) Same as embodiment 1

[0071] (2) Add 627 parts of the above-mentioned 4# base glue and 20 parts of the above-mentioned bistrimethoxy-terminated polysiloxane with a viscosity of 1020 mPa.s into the planetary stirring tank, and stir for 30 minutes at a speed of 40 r / min.

[0072] ⑶Add 3.5 parts specific surface area 150m 2 / g, fumed silica whose surface was treated with silazane, stirred at 45r / min for 30 minutes.

[0073] (4) (5) with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap