Deep foundation pit protective fence and protective fence mounting method

A technology for guardrails and deep foundation pits, which can be used in fencing, excavation, infrastructure engineering, etc., and can solve problems such as poor installation quality of guardrails

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

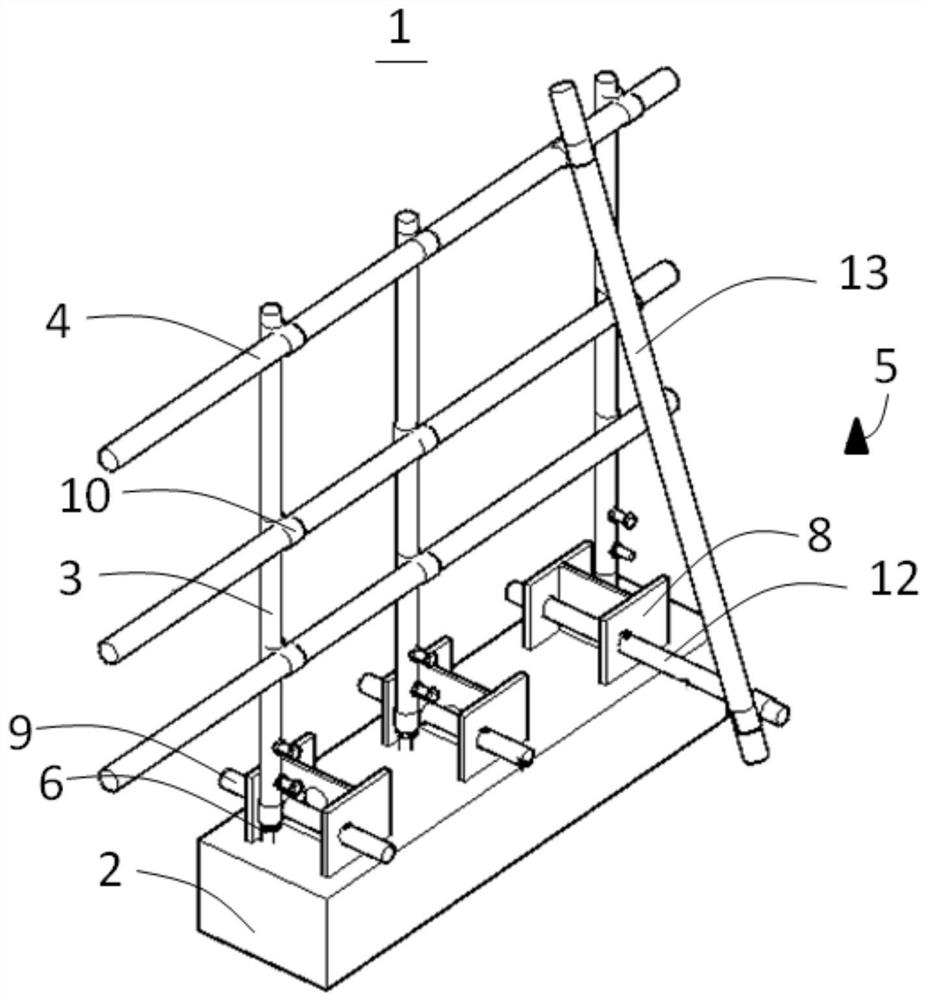

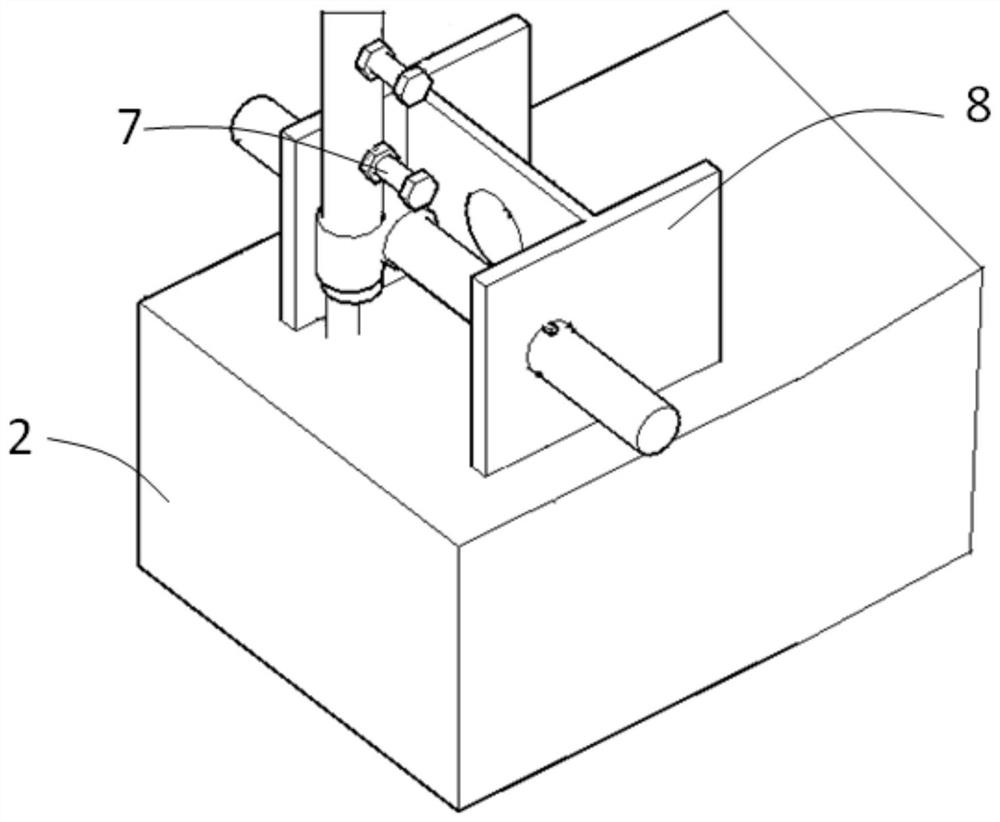

[0036] Please refer to figure 1 , with reference to figure 2 , the application provides a deep foundation pit protection fence, which is suitable for the situation that the pre-embedded steel bar 6 is relatively close to the H-shaped steel 8 of the crown beam 2; The pre-embedded steel bars 6 are embedded in parallel at intervals, and the pre-embedded steel bars 6 are buried in the concrete of the crown beam 2 by 200 mm, and the exposed 400 mm; the bottom ends of a plurality of vertical steel pipes 3 are fixedly socketed on the top of the pre-embedded steel bars 6 through bolts 7; A plurality of horizontal bars 4 are fixedly installed on a plurality of vertical steel pipes 3 in parallel and at intervals, and are arranged at intervals along the height direction of the vertical steel pipes 3. on a vertical steel pipe 3; a plurality of fixed structures 5 are fixedly installed on the crown beam 2 at intervals, and are fixedly connected to the corresponding vertical steel pipes 3 ...

no. 2 example

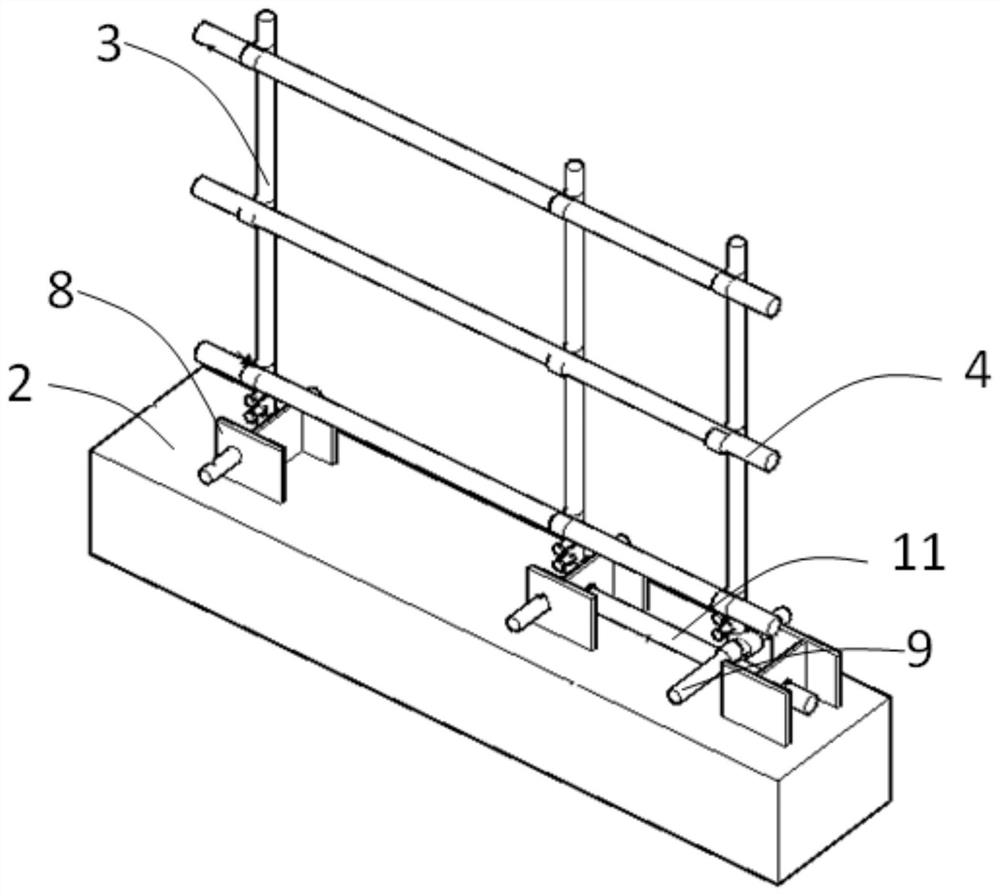

[0049] Please refer to image 3 , the application provides a deep foundation pit protection fence, which is mainly applicable to the situation where the distance between the H-shaped steel 8 and the embedded steel bar 6 is far away. The deep foundation pit protection fence in this embodiment is roughly the same as that in the first embodiment. The difference is that the connection between the fixed structure 5 and the vertical steel pipe 3 is different.

[0050] Further, in this embodiment, the fixed structure 5 includes H-shaped steel 8, longitudinal short steel pipe 11 and first transverse short steel pipe 9; ; The web of each H-shaped steel 8 is provided with a corresponding second hoisting hole, and the two ends of the longitudinal short steel pipe 11 respectively pass through two adjacent second hoisting holes, and are fastened to the first hoisting hole by a wooden wedge. Two hoisting holes. At the same time, the middle part of the longitudinal short steel pipe 11 is v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com