Automatic leveling system for photoelectric rotary table and automatic leveling photoelectric rotary table

A photoelectric turntable and automatic leveling technology, which is applied in the direction of machine/stand, measuring device, instrument, etc., can solve the problems that cannot meet the second-level precision requirements of the photoelectric turntable, is easily disturbed by environmental factors, and takes a long time to level. Realize the effect of high-precision automatic leveling, less personnel occupation, and shorter time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

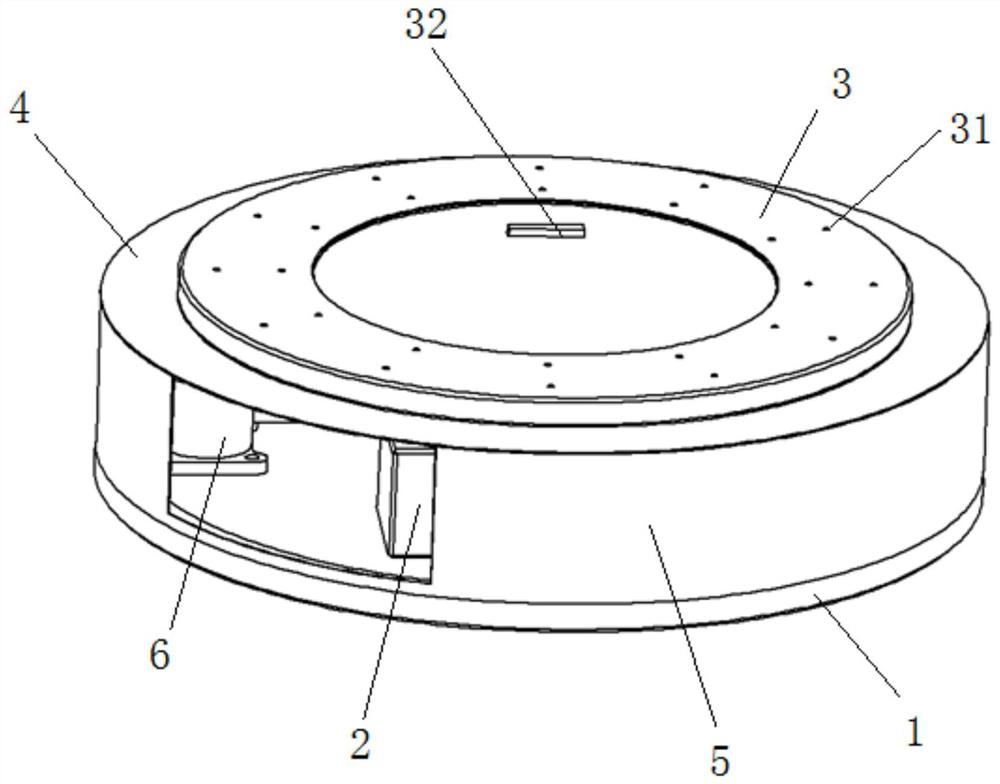

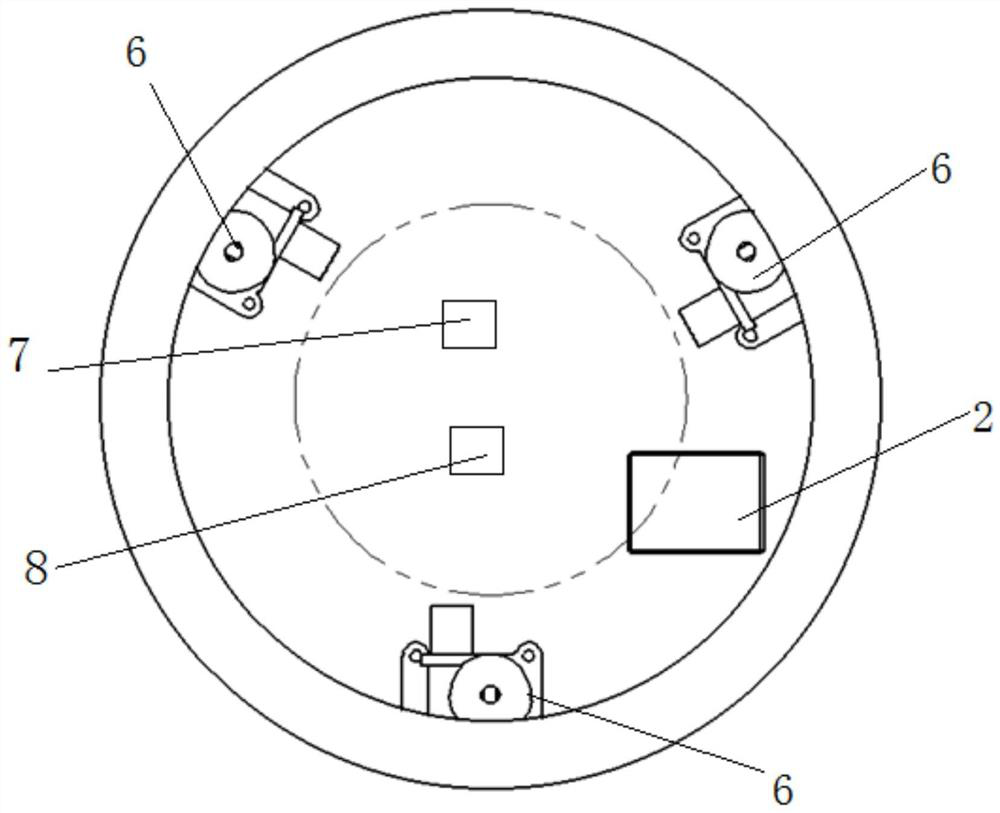

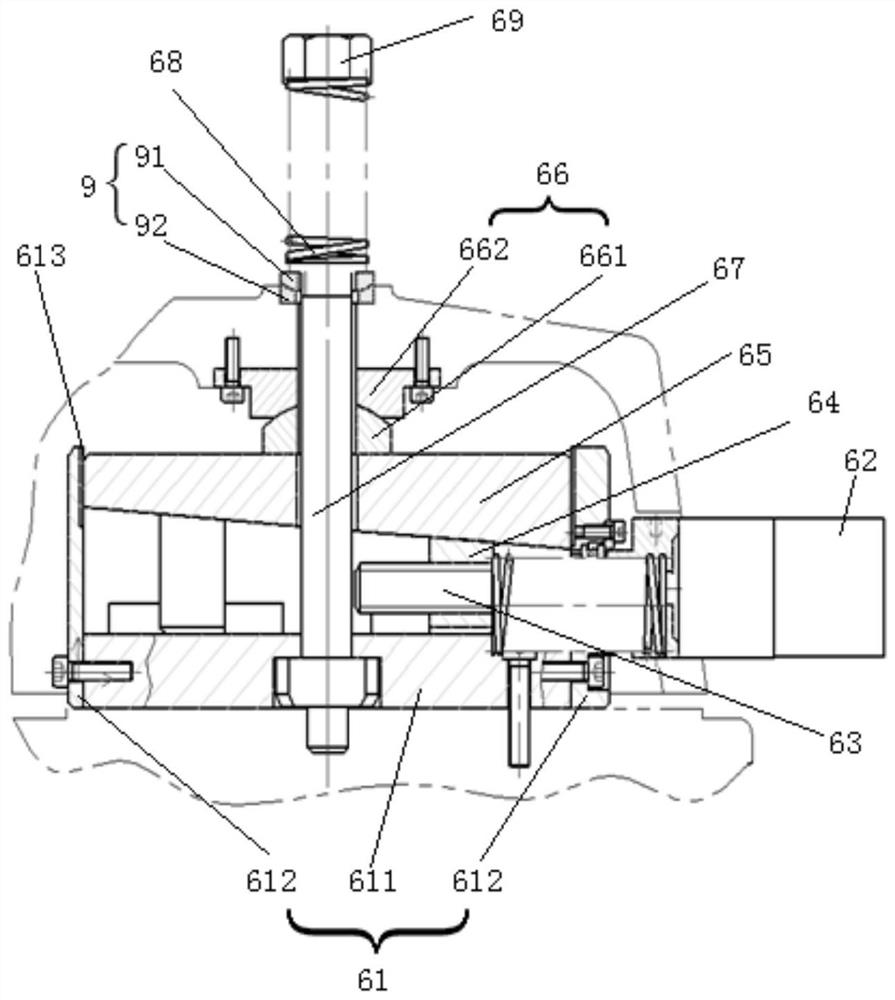

[0056] Such as figure 1 and figure 2 As shown, an automatic leveling system for a photoelectric turntable includes a base 1, an electric control system 2 arranged on the base 1, an adjustment platform 3 arranged above the base 1, and an elastic body arranged on the circumferential side of the adjustment platform 3. The sealing ring 4, the sealing shell 5 between the circumferential side of the elastic sealing ring 4 and the circumferential side of the base 1, the three electric adjustment leg assemblies 6 whose circumference is evenly distributed between the base 1 and the adjustment platform 3; the base 1 , the sealing shell 5, the elastic sealing ring 4 and the adjustment platform 3 form a hollow shell, and the electric control system 2 is located in the hollow shell.

[0057] The adjustment platform 3 is also provided with an electrical interface 32 and a plurality of general-purpose mechanical interfaces 31 along the circumference. The plurality of mechanical interfaces ...

Embodiment 2

[0088] The difference from Embodiment 1 is that there are four electrically adjustable outrigger assemblies 6, which can be adjusted by using the connected two electrically adjustable outrigger assemblies 6 as fulcrums and the remaining two electrically adjustable outrigger assemblies 6 to form surface-to-face adjustment. , this adjustment method is more convenient.

Embodiment 3

[0090] The difference from Embodiment 1 is that both the inclination sensor 7 and the electronic level 8 are arranged on the photoelectric turntable, and the flatness of the photoelectric turntable is directly monitored by the inclination sensor 7 and the electronic level 8, so that the leveling accuracy of the photoelectric turntable is higher.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap