Automatic sorting equipment and method for injection molded parts

A technology for automatic sorting and injection molded parts, applied in the field of image processing, can solve the problems of multiple inspectors, many batches, and difficult to guarantee the reliability of detection, and achieve the goal of improving sorting efficiency, reducing costs, and improving sorting accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The technical solutions in the embodiments of the present application will be described below with reference to the drawings in the embodiments of the present application.

[0048] Like numbers and letters denote similar items in the following figures, so that once an item is defined in one figure, it does not require further definition and explanation in subsequent figures. Meanwhile, in the description of the present application, the terms "first", "second" and the like are only used to distinguish descriptions, and cannot be understood as indicating or implying relative importance.

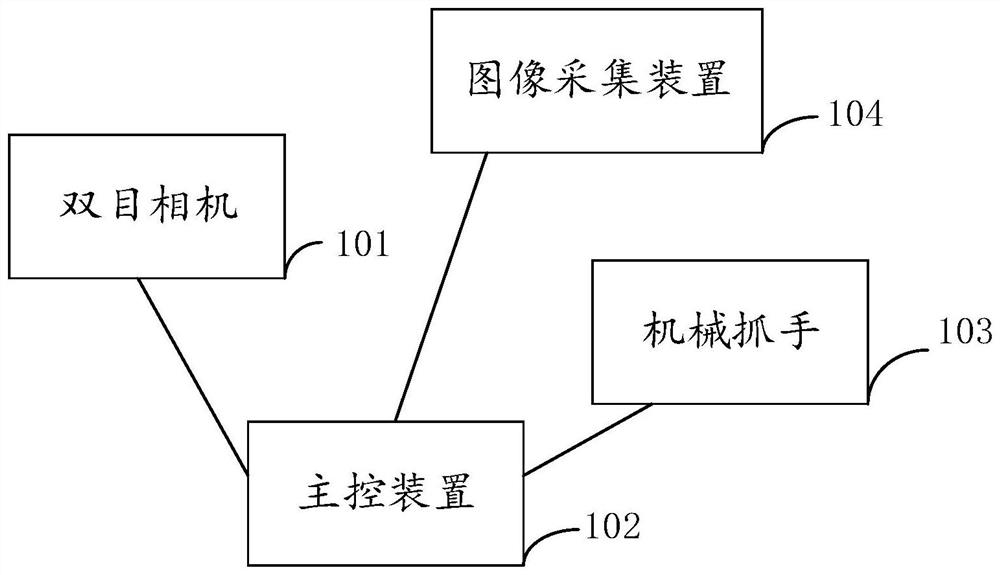

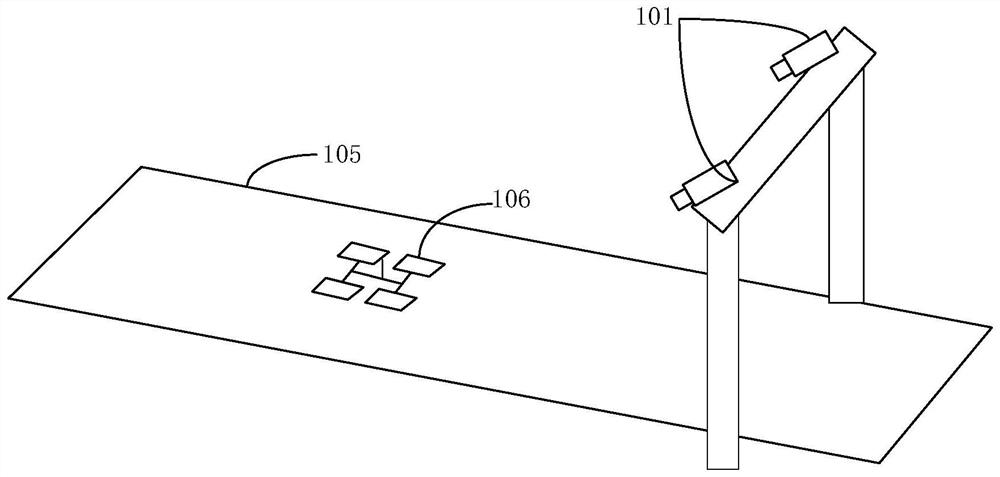

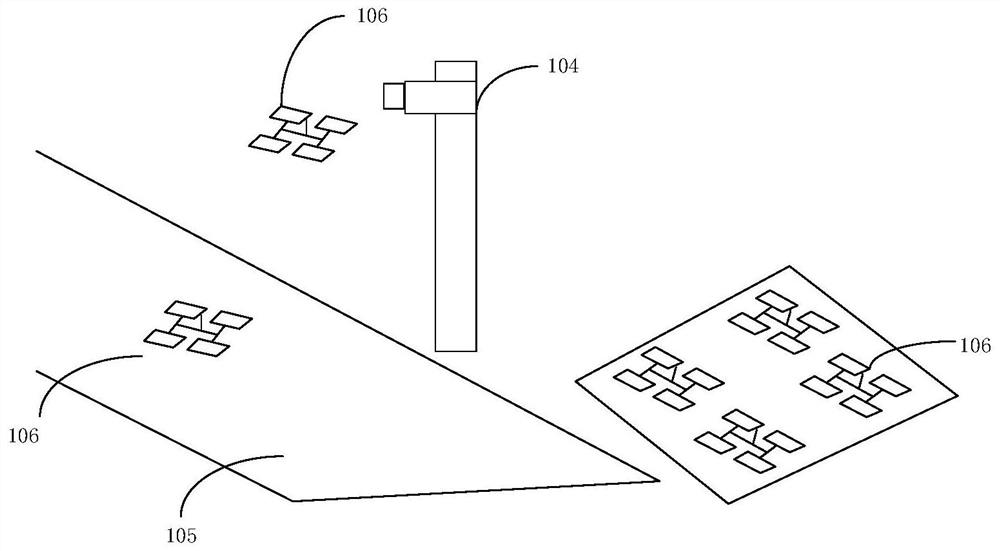

[0049] figure 1 It is a block diagram of an automatic sorting equipment for injection molded parts provided by the embodiment of this application. Such as figure 1 As shown, the device includes: a binocular camera 101, a main control device 102, a mechanical gripper 103 and an image acquisition device 104. The main control device 102 is respectively connected to the binocular camera 1...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap