Fire fighting box

A fire box and fire hydrant technology, applied in fire rescue, etc., can solve the problems of wasting time and physical strength, inconvenient pulling process, heavy fire hose, etc., and achieve the effects of energy saving, convenient opening, and avoiding running back and forth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

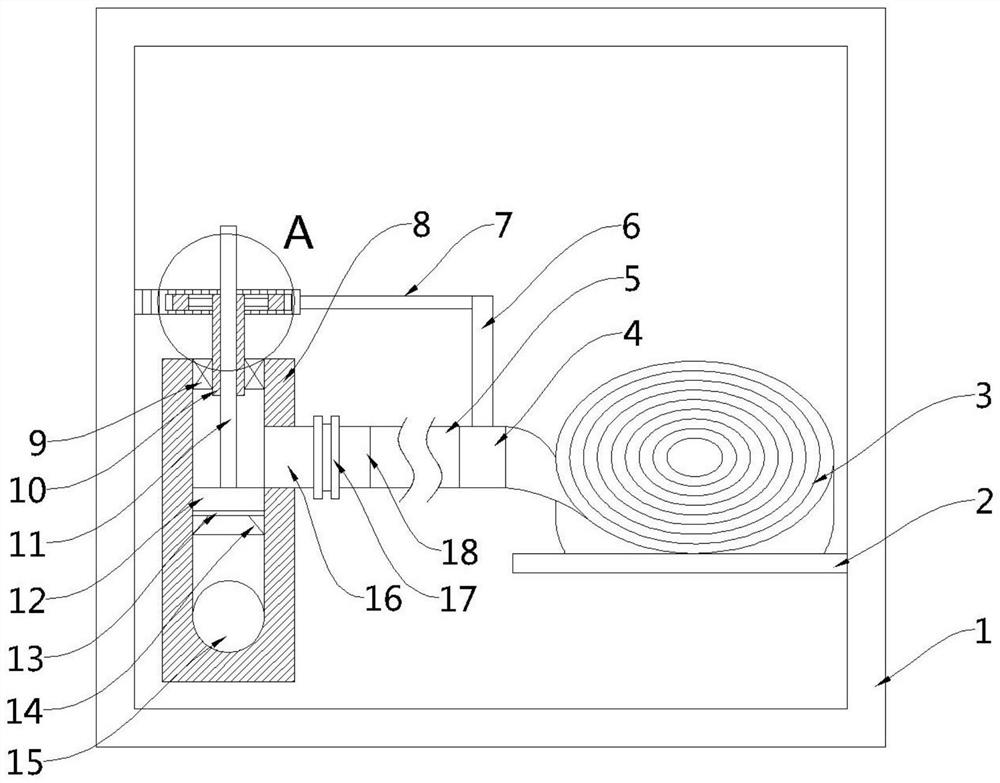

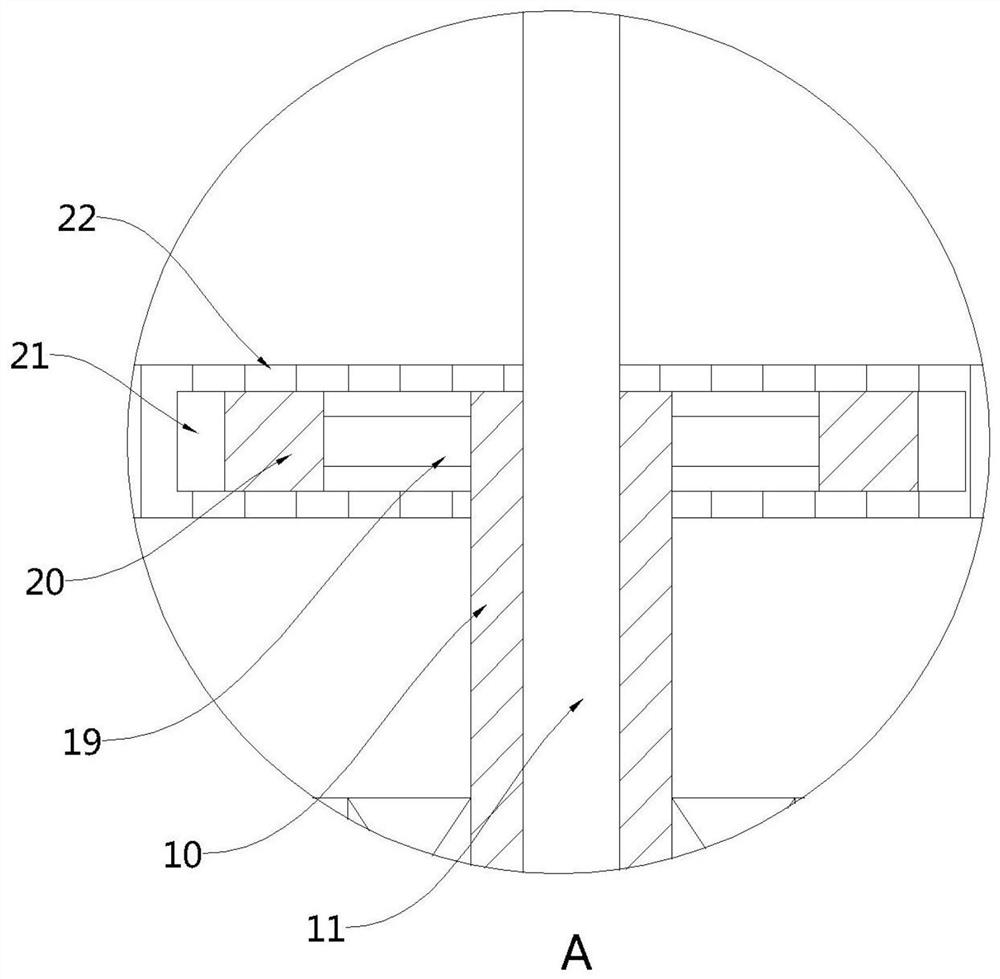

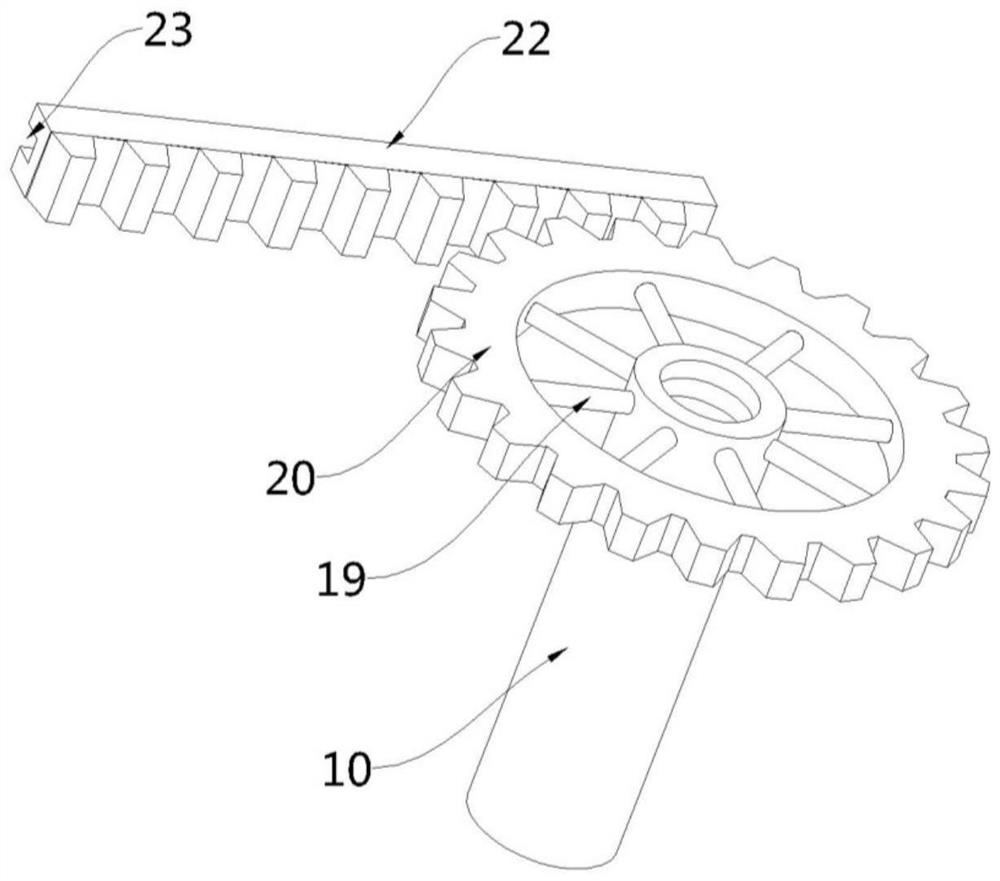

[0025] see Figure 1-3 , the present embodiment provides a fire fighting box, including a box body 1, a fire hydrant body 8 is arranged inside the box body 1, a third joint 16 is arranged on the upper part of the side wall of the fire hydrant body 8, and the side wall of the fire hydrant body 8 is The lower part of the wall is connected to the external water supply pipe network (not shown) through the water inlet pipe 15, the valve body 12 is movable inside the fire hydrant body 8, the sleeve 10 is installed on the upper part of the fire hydrant body 8, and the upper part of the valve body 12 is fixedly arranged There is a valve stem 11, the upper end of the valve stem 11 extends to the inside of the sleeve 10 and is threadedly engaged with the sleeve 10, the upper part of the side wall of the sleeve 10 is connected with a runner 20 through several connecting rods 10, the The outside of the runner 20 is replaced with a number of toothed pieces 21, and the inner wall of the box...

Embodiment 2

[0036] seefigure 1 , a fire box, compared with Example 1 in this embodiment, a holding plate 2 for supporting the fire hose 3 is also fixedly installed inside the box 1, and the fire hose 3 is fixed when not in use Coiled on the upper part of the holding plate 2 .

[0037] The embodiment of the present invention can realize the remote opening of the fire hydrant body 8. Compared with the prior art, it has the advantage of convenient opening of the fire hydrant body 8, avoiding the running back and forth between the fire scene and the fire box by the firefighters, saving Physical strength; by pulling one end of the fire hose 3, the fire hose 3 is unfolded from the inside of the box body 1. After the fire hose 3 is fully unfolded, the first joint 4 can be driven away from the fire hydrant body 8, and then the support vertical bar 6 can be driven , the support bar 7 and the rack 22 move horizontally inside the box body 1, and the sleeve 10 is driven to rotate by the meshing effec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com