Feeding equipment in assembly line

A technology for assembling lines and feeding equipment, which can be used in conveyors, conveyor objects, transportation and packaging, etc., and can solve problems such as the impact of parts precision and the impact and wear of conical parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

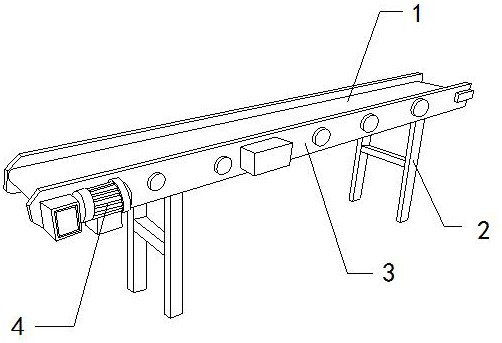

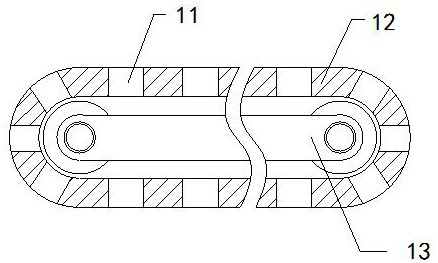

[0026]As for examplefigure 1 -exampleFigure 5 Shown:

[0027]The present invention provides a feeding equipment in an assembly line. The structure includes a conveyor belt 1, a support frame 2, a bearing platform 3, and a driver 4. The support frame 2 is welded to the bearing platform 3, and the driver 4 is installed on the bearing platform 3. The conveyor belt 1 is movably engaged with the carrying platform 3; the conveyor belt 1 includes an introduction groove 11, a belt body 12, and a transmission frame 13. The introduction groove 11 and the belt body 12 are an integrated structure. The belt body 12 is movably engaged with the transmission frame 13.

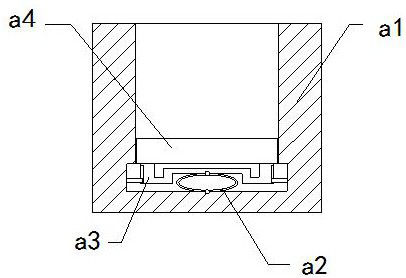

[0028]Wherein, the introduction groove 11 includes an outer frame a1, an elastic ring a2, a shrink frame a3, and a lower shrink plate a4. The elastic ring a2 is installed between the bottom of the shrink frame a3 and the bottom of the inner wall of the outer frame a1. The frame a3 is movably engaged with the outer frame a1, the lower shri...

Embodiment 2

[0034]As for exampleFigure 6 -exampleFigure 8Shown:

[0035]Wherein, the outer frame a1 includes a force rod c1, a resilient bar c2, a frame c3, the force rod c1 is movably engaged with the frame c3, and the resilient bar c2 is installed between the force rod c1 and the frame c3 At the same time, the force rod c1 is provided with six, and three of them are a group of evenly distributed symmetrically on the inner side of the frame c3. The pressure rod c1 can be squeezed by the conical part to make the force rod c1 Shrink backward along the frame c3.

[0036]Wherein, the force rod c1 includes a contact plate c11, a suction plate c12, a reel c13, and a receiving plate c14. The contact plate c11 is movably engaged with the right side of the receiving plate c14 through the reel c13, and the suction plate c12 It is an integrated structure with the contact plate c11. The tapered part generates a leftward thrust to the contact plate c11, which can make the contact plate c11 shrink backwards to fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com