Embedded beam falling prevention device

An anti-falling beam, built-in technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as beam damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

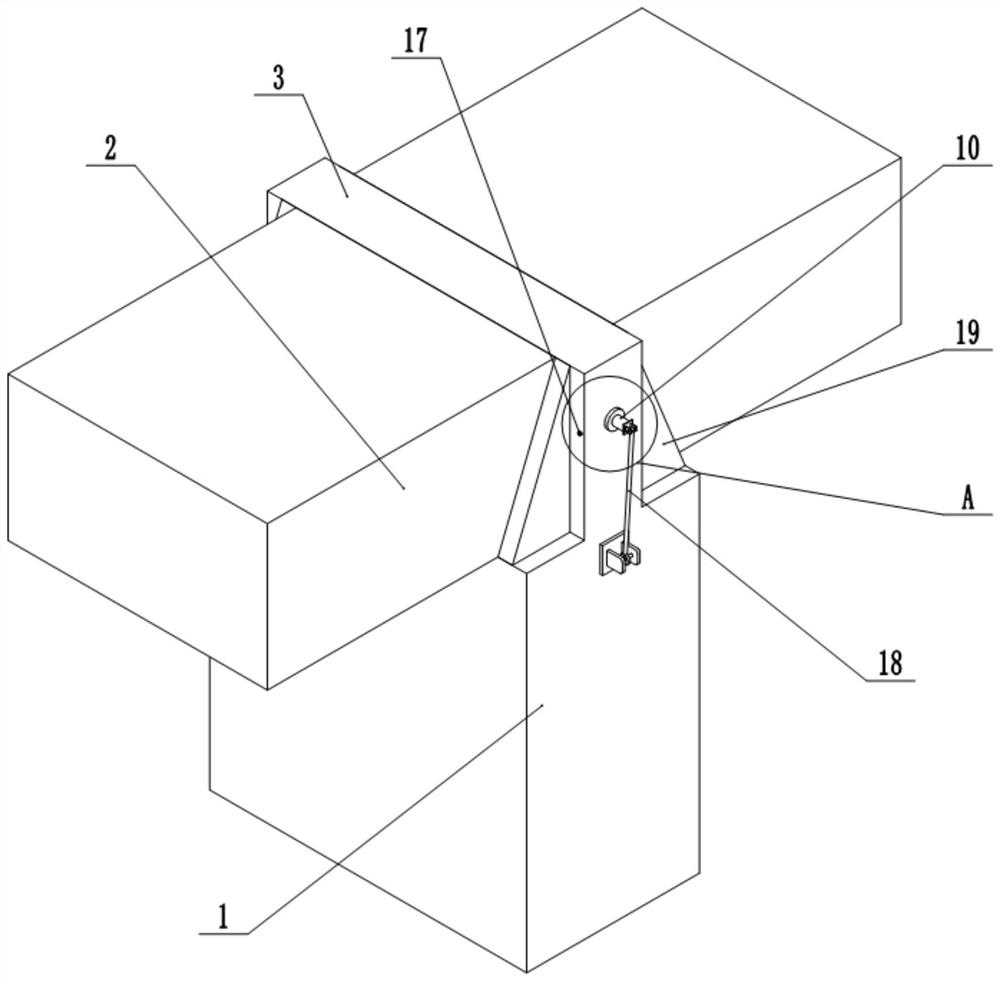

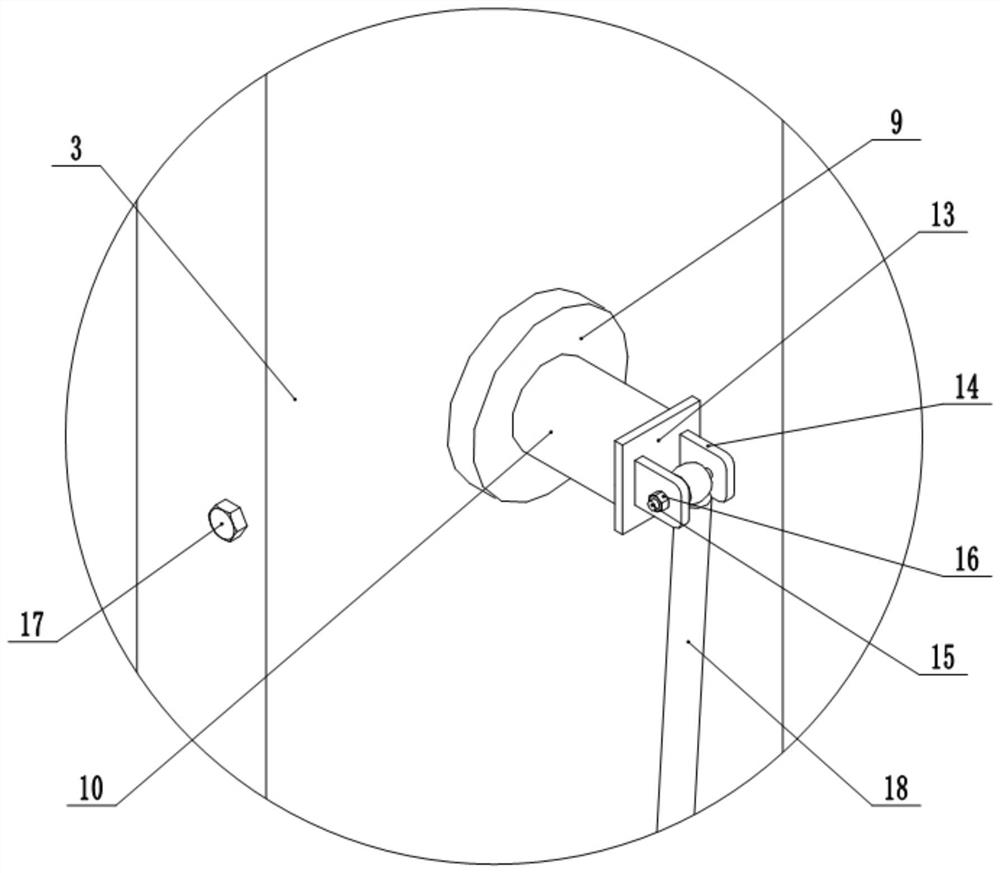

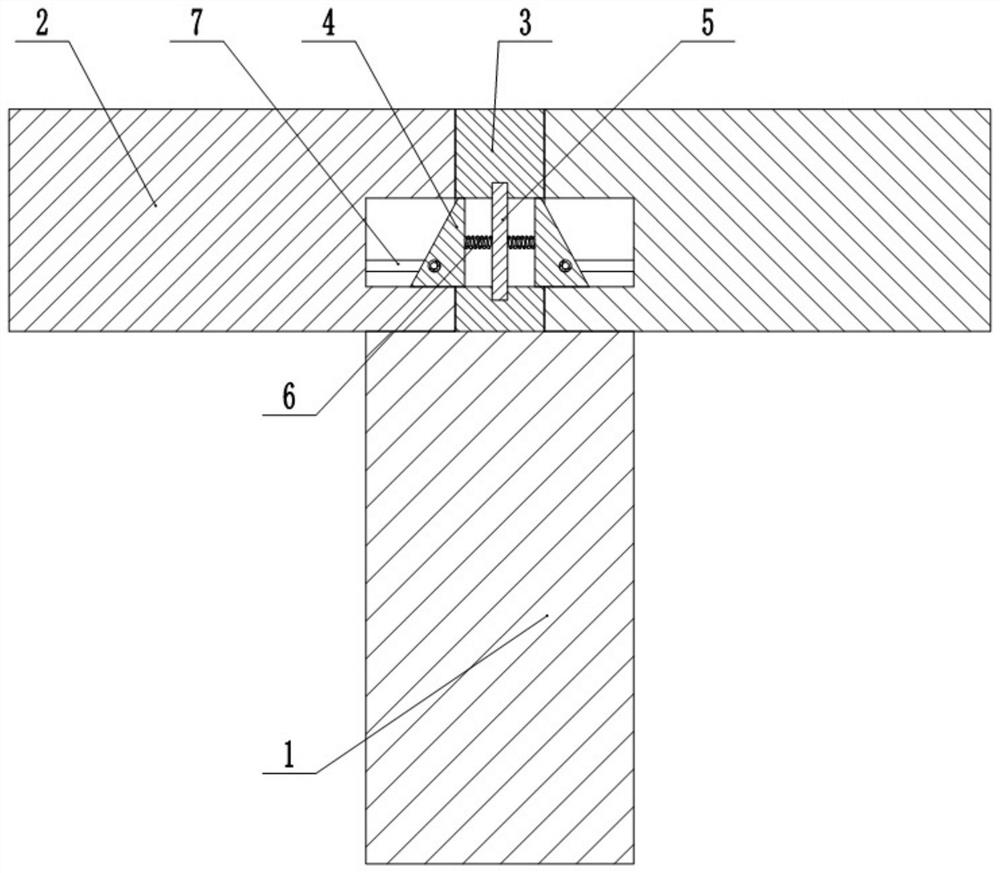

[0024] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Shown: a built-in anti-drop beam device, including a bridge pier 1, the upper surface of the bridge pier 1 is fixed with a partition 3, the partition 3 is perpendicular to the bridge pier 1, and the partition 3 is provided with a horizontally arranged through groove, inside the through groove The limit column 4 is horizontally slidably connected, and the two ends of the limit column 4 protrude from the through groove, and the end faces at both ends of the limit column 4 are all inclined inwardly. Positioning column 5 is arranged to the direction, and the diameter of positioning column 5 contacts with the side wall of chute, and the two ends of positioning column 5 pass through limit column 4 and connect with the inner wall of through groove, and the two ends of chute are all fixed with toward positioning bar. Spring 6; two sections of beam body 2 are placed on the pier 1, the beam body 2 ...

specific Embodiment approach

[0025] Lift the beam body 2 at the left end and place it at the specified position. During the process of lowering the beam body 2 at the left end, the beam body 2 squeezes the inclined surface at the left end of the limit column 4, so that the limit column 4 slides to the right, and the beam body 2 at the left end reaches the designated position. After the position, the limit column 4 slides to the initial position under the action of the spring 6 and the positioning column 5, and the left end of the limit column 4 stretches into the cavity of the left end beam body 2; The limit rod 8 on the side is squeezed by the inner wall of the cavity and slides into the groove until the limit rod 8 contacts the limit groove 7. At this time, the limit rod 8 pops up under the action of the spring 6 and extends into the limit In groove 7; Place the beam body 2 at the right end after hoisting and place it at the designated position. During the process of putting down the beam body 2 at the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com