Interior wall painting equipment for building construction

A technology for building construction and interior walls, which is applied in the direction of architecture and building construction, etc., to achieve the effects of good safety, improved wall painting effect, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

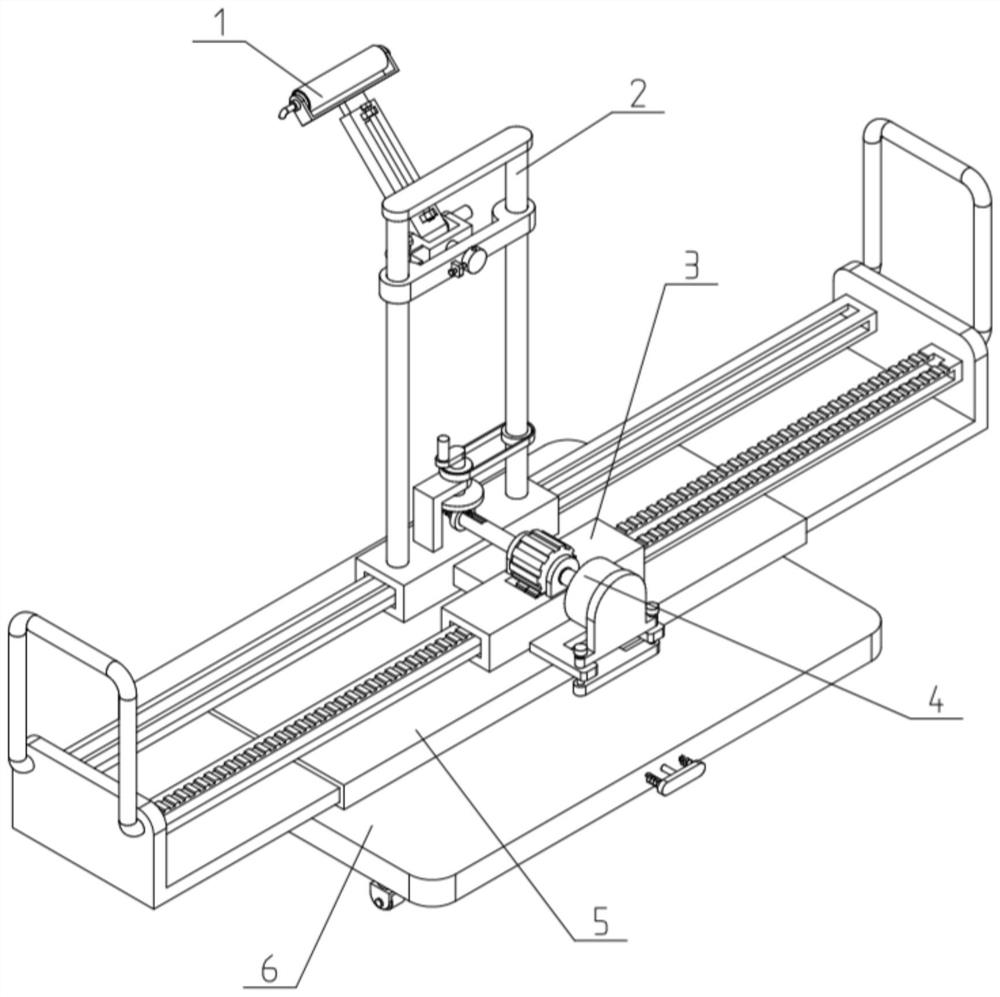

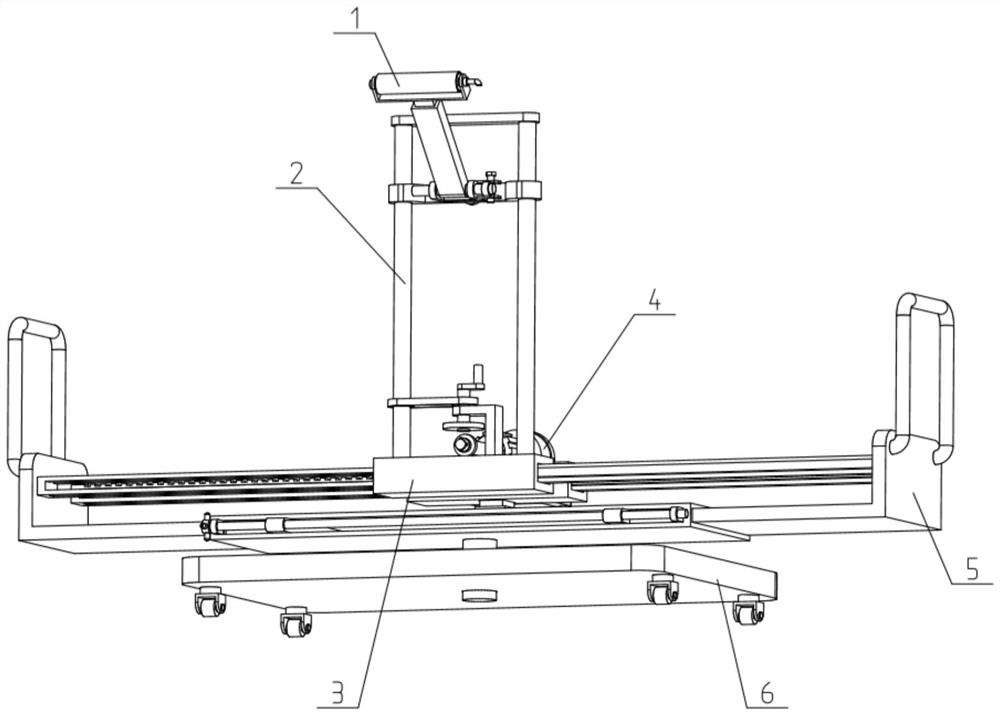

[0041] like Figure 1-16 As shown, the interior wall painting equipment for building construction includes a painting mechanism 1, a lifting control mechanism 2, a sliding seat mechanism 3, a motor drive mechanism 4, a bracket mechanism 5 and a base mechanism 6, and the painting mechanism 1 is matched and connected to the the lift control mechanism 2; the lift control mechanism 2 is matched and connected to the sliding seat mechanism 3; the sliding seat mechanism 3 is matched and connected to the bracket mechanism 5; on the base mechanism 6 ; the motor driving mechanism 4 is matched and connected to the sliding seat mechanism 3 ; the motor driving mechanism 4 is drivingly connected to the bracket mechanism 5 or the lifting control mechanism 2 . The interior wall painting equipment for building construction of the present invention can be used to drive the entire body of the present invention to move through the base mechanism 6 by pushing the bracket mechanism 5, so as to be e...

specific Embodiment approach 2

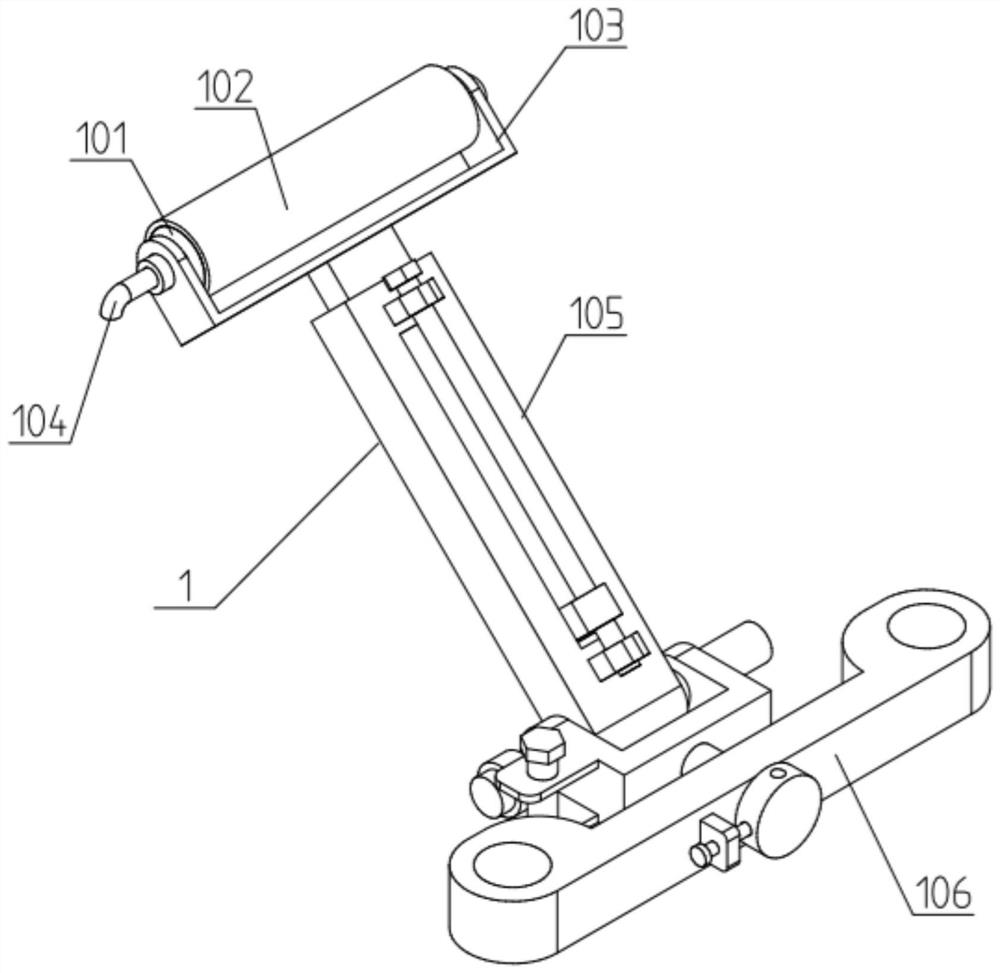

[0042] like Figure 1-16 As shown, the painting mechanism 1 includes a painting roller 101, a bristle sleeve 102, a door-shaped roller frame 103, a rotating nozzle 104, a turning bracket assembly 105 and a lifting bracket assembly 106; the roller surface of the painting roller 101 is fixedly connected with bristles Sleeve 102; the roller surface of the paint roller 101 is provided with a plurality of slurry through holes that communicate with the interior of the paint roller 101; ; The door-shaped roller frame 103 is fixedly connected to the overturning bracket assembly 105; The overturning bracket assembly 105 is fixedly connected to the lifting bracket assembly 106; 2; one end of the rotating pipe 104 is sealed and rotatably fitted inside the paint roller 101, and the other end of the rotating pipe 104 is fixedly connected and communicated with a suction pipe with a suction pump. The painting roller 101 and the bristle sleeve 102 inside the painting mechanism 1 cooperate to...

specific Embodiment approach 3

[0043] like Figure 1-16 As shown, the flipping bracket assembly 105 includes a flipping frame 105A, a telescopic frame 105B, a guide slider 105C, a first screw 105D and a screw base 105E; the inner end of the flipping frame 105A is fixedly connected to the lifting bracket assembly 106 ; The outer end of the turning frame 105A is slidingly connected to one end of the telescopic frame 105B; the other end of the telescopic frame 105B is fixedly connected to the middle of the door-shaped roller frame 103; the inner end of the telescopic frame 105B is fixedly connected Wire slider; the guide slider 105C is slidably fitted in the guide slideway of the flip frame 105A; the guide slider 105C is threadedly fitted in the middle of the first screw rod 105D; the first screw rod 105D is rotatably fitted On the screw base 105E; the screw base 105E is fixedly connected to the turning frame 105A. The inversion bracket assembly 105 is used to cooperate with the lift bracket assembly 106 to p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com