An environmentally friendly roller brush

A kind of roller brush, environmental protection technology, applied in the direction of construction, coating, building structure, etc., can solve the problems of unenvironmental protection, waste of paint, dirty working environment, etc., to prevent dripping, improve efficiency, save the time of dipping paint effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

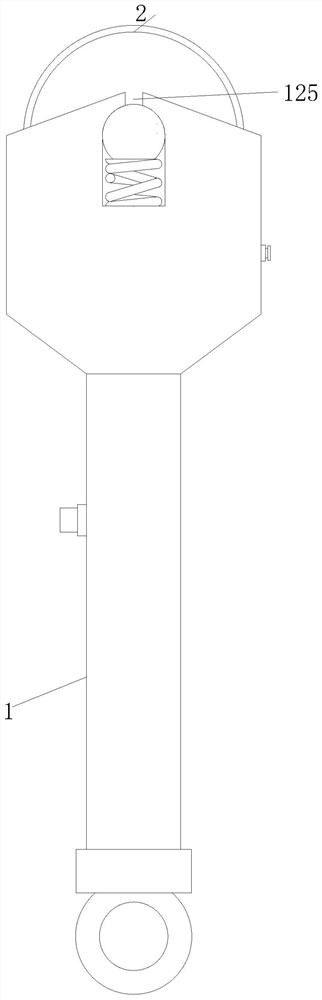

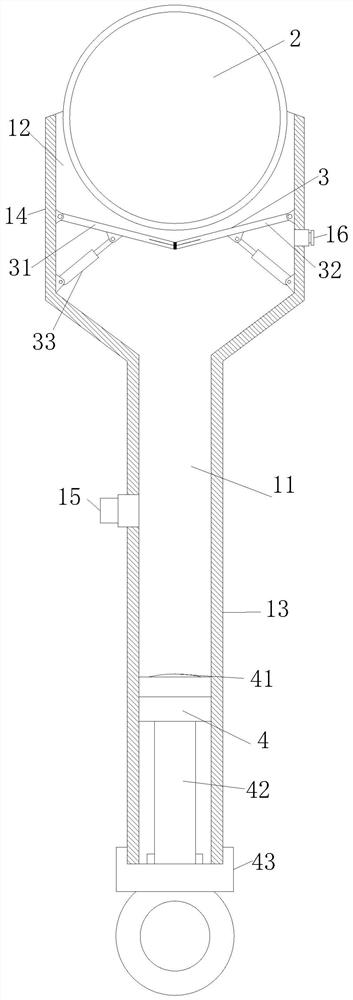

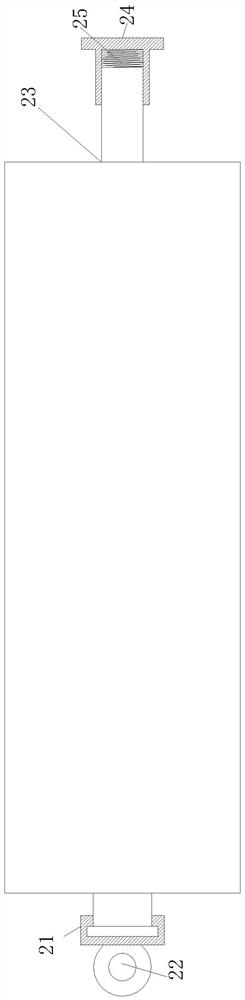

[0027] A kind of environment-friendly roller brush that the present invention provides based on the above-mentioned purpose, as a kind of embodiment of the present invention, such as figure 1 and figure 2 As shown, it includes a grip part 1, a material storage chamber 11 is provided inside the grip part 1, an opening 12 is provided at one end of the grip part 1; a drum main body 2, and the drum main body 2 is rotatably installed In the opening 12, and can move along the length direction of the grip part 1; the closing assembly 3, the closing assembly 3 is arranged in the opening 12; the pressurizing assembly 4, the pressurizing assembly 4 is installed in The end of the gripping portion 1 away from the opening 12; when i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com