Parameter selection and optimization method for diesel particulate filter

A particle filter and parameter selection technology, which is applied in design optimization/simulation, complex mathematical operations, special data processing applications, etc., can solve the problems of insufficient consideration of parameters and the inability to realize the optimal selection of diesel engine particle filter, and achieve The overall effect of influencing factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

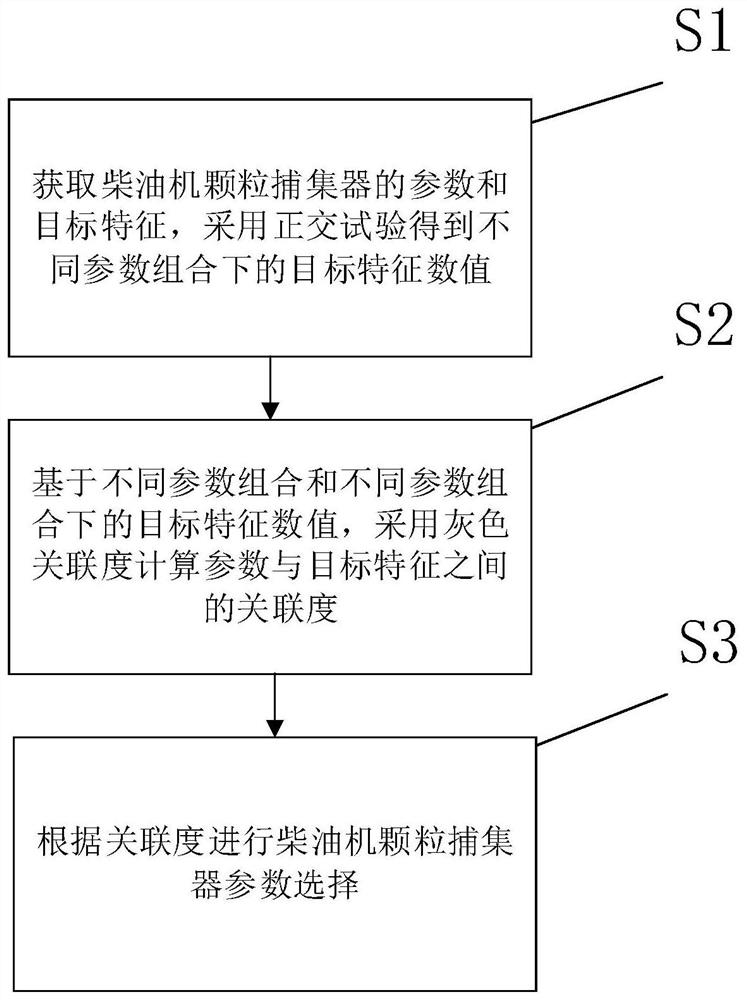

[0049] This embodiment provides a method for selecting and optimizing parameters of a diesel particulate filter, including the following steps:

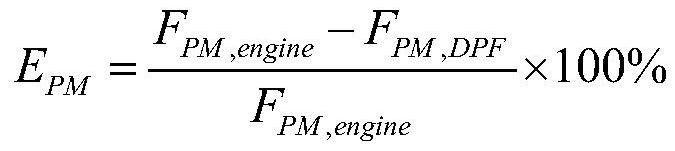

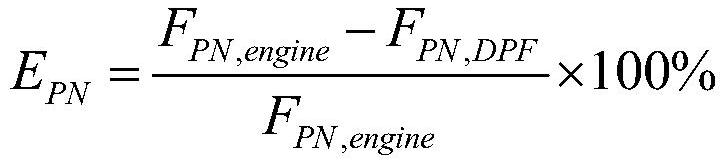

[0050] Step S1: Obtain the parameters and target characteristics of the diesel particulate filter, and use the orthogonal test to obtain the target characteristic values under different parameter combinations; the orthogonal test is based on the engine bench test method, and the parameters include structural parameters and catalyst parameters. The structural parameters include Wall thickness, pore density and porosity, catalyst parameters include catalyst loading and catalyst ratio; target characteristics include PM emission reduction efficiency, PN emission reduction efficiency and front-to-back pressure difference; PM emission reduction efficiency E PM for:

[0051]

[0052] Among them, F PM,engine Indicates the diesel engine PM emission factor, F PM,DPF Indicates the PM emission factor after the diesel particulate filter; ...

specific example

[0081] (1) Determine the design variables of diesel particulate filter

[0082] First, determine the diesel particulate filter design variables. Diesel particulate filter design variables include structural parameters and catalyst parameters. In terms of structural parameters, the more commonly used optimization parameters include wall thickness, pore density, porosity, etc.; in terms of catalysts, the performance of diesel particulate filters is significantly affected by the catalyst loading and the Pt / Pd ratio (catalyst ratio). Therefore, the wall thickness (ω), pore density (σ) and porosity (ε) are selected as the structural parameters of the diesel particulate filter, and the catalyst loading and catalyst ratio are selected as the catalyst parameters.

[0083] (2) Determine the target characteristics

[0084] Particulate matter emission reduction performance and back pressure characteristics are the most important performance of diesel particulate filter. When optimizin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com