Lamp polishing and trimming equipment

A technology of trimming and equipment, applied in the field of electric power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

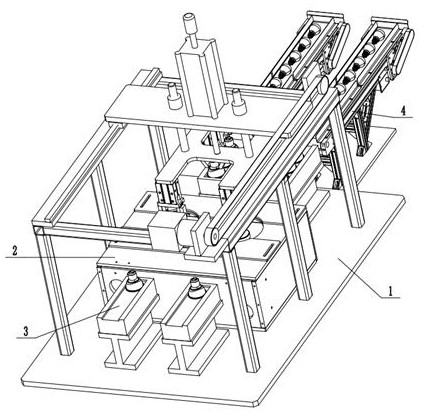

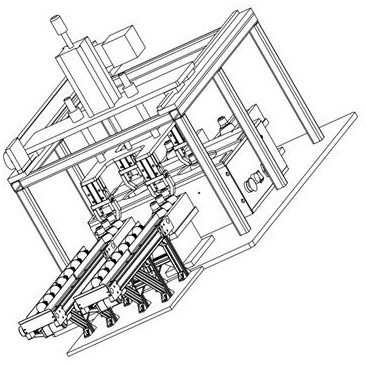

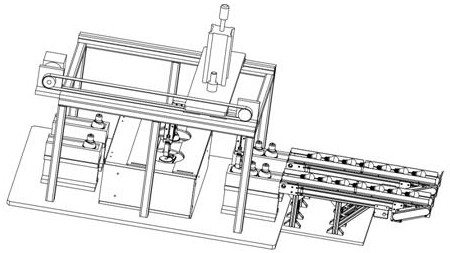

[0021] Example: such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 The lamp grinding and trimming equipment shown includes: a base movable mechanism 1 , a trimming and polishing mechanism 2 , a finished product placement part 3 , and a transport mechanism 4 .

[0022] Base movable mechanism 1 comprises: base plate 101, support frame 102, connecting plate 103, drive motor 104, driving wheel 105, belt 106, driven wheel 111 and movable clamping mechanism; The frame 102 can support equipment; the lower end surface of the connecting plate 103 is fixedly connected with the upper end surface of the supporting frame 102; the driving motor 104 is fixedly installed on the connecting plate 103, and its motor 404 shaft is fixedly connected with the driving wheel 105; the connecting plate 103 is provided with Driven wheel 111; Belt 106 is rolled with driving wheel 105 and driven wheel 111; Movable clamping me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com