Automatic production line collaboration device and control method thereof

An automated production line and main production line technology, applied in the direction of program-controlled manipulators, manufacturing tools, manipulators, etc., can solve problems such as wasting electric energy, difficulty in developing productivity, unreasonable production line scheduling, etc., and achieve the effect of simplifying installation work and improving installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

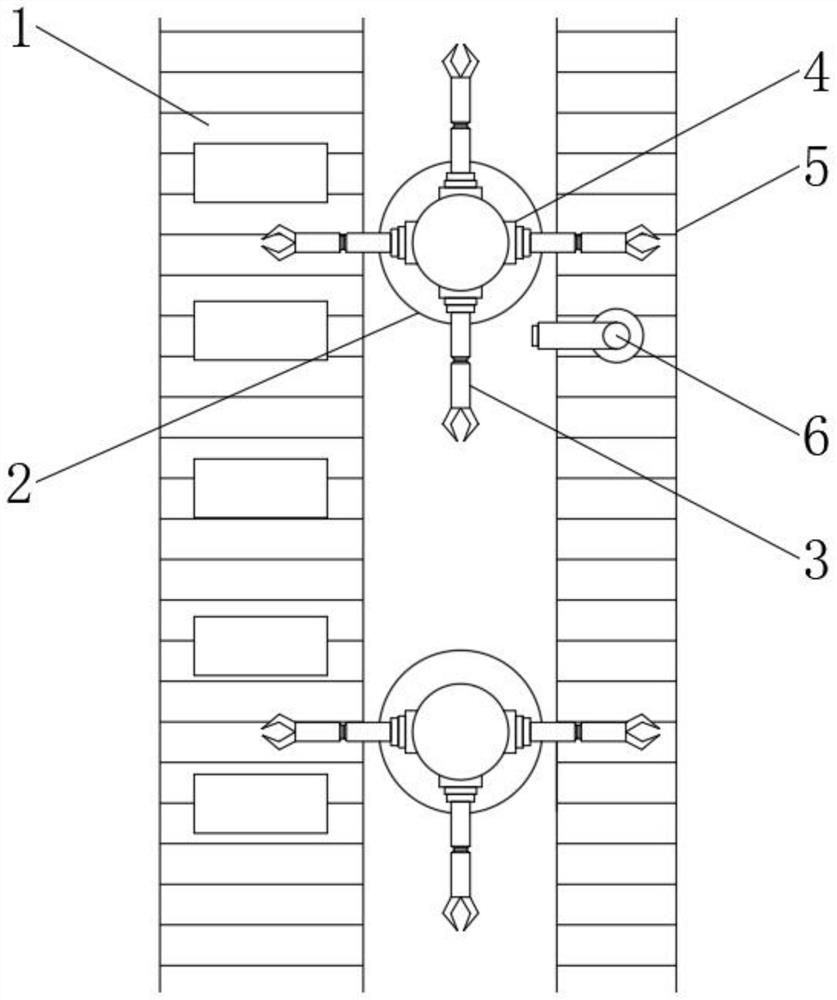

[0043] see figure 1 , an automatic production line coordination device, including a main production line 1 and a plurality of production stations 2, the production station 2 is embedded with a main controller module, and the outer end of the production station 2 is equipped with a plurality of auxiliary connection seats 4, the auxiliary connection A production manipulator 3 is detachably mounted on the seat 4, a sub-cooperative transmission line 5 is installed laterally on the main production line 1, and a sub-coordination manipulator 6 is installed on the sub-coordination transmission line 5.

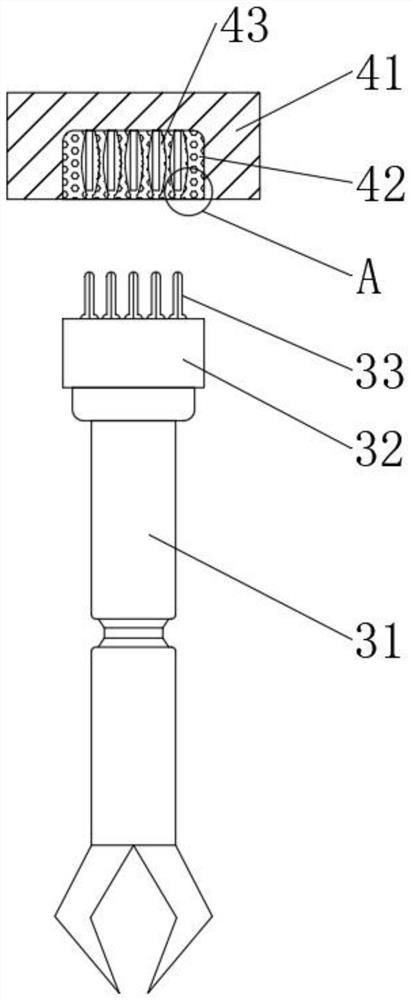

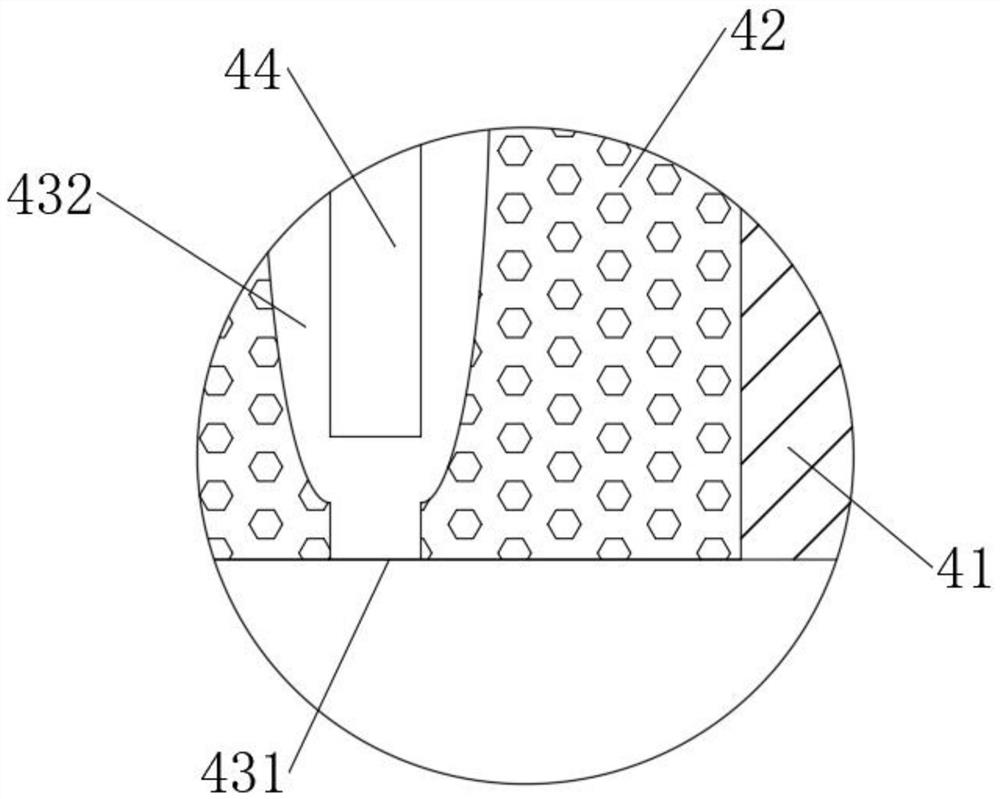

[0044] see figure 2 and Figure 4 The production manipulator 3 includes a manipulator body 31 connected in sequence, a control base 32 and a plurality of connection tentacles 33, the control base 32 is embedded with a sub-controller module, and the connection tentacles 33 include a male connection end 331 and a plurality of phase-change locking valve sleeves 332, the phase-change lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com