Vehicle lifting system and method

A lifting system and vehicle technology, applied in the field of automation, can solve the problem that the vehicle lifting system is difficult to be compatible at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

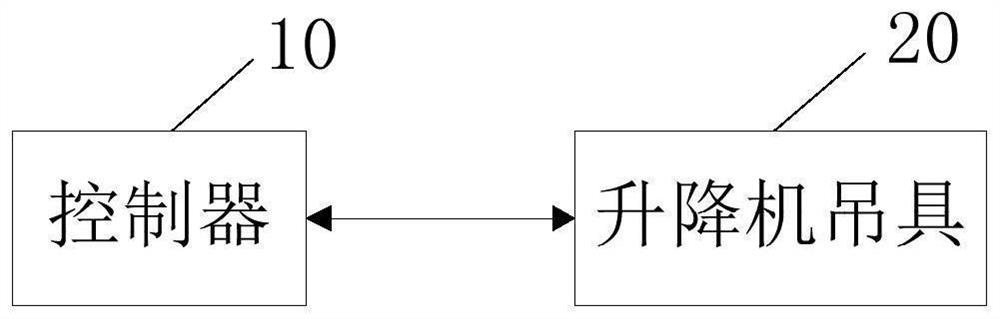

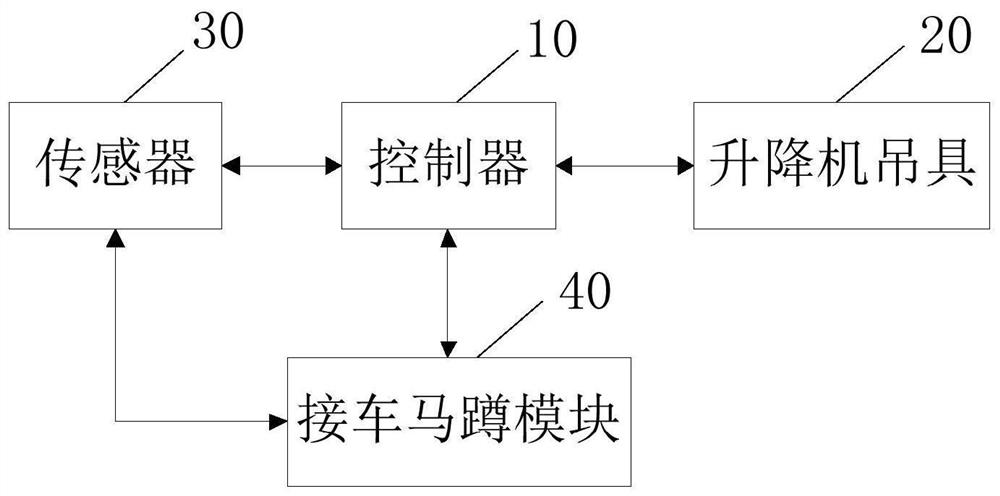

[0056] The vehicle lifting system includes: a controller 10 and an elevator spreader 20;

[0057] The controller 10 is used to acquire the vehicle model information of the vehicle being transferred, search for the corresponding limiter number according to the vehicle model information, and send a control command and the limiter number to the elevator spreader 20 .

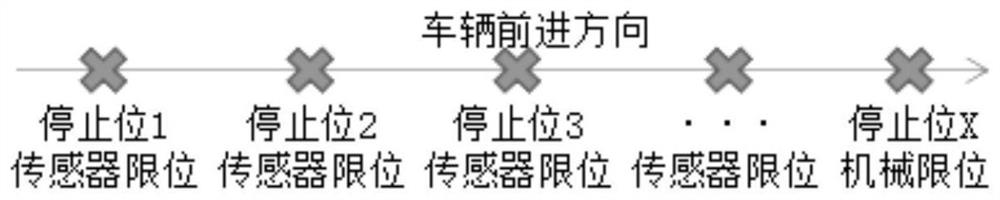

[0058]It should be understood that the vehicle to be transferred is suspended at the waiting station, and the sensor passes through the model feature recognition point to identify the model information and upload the model information to the controller 10, which can be a programmable logic Controller (Programmable Logic Controller, PLC), the controller 10 judges that the vehicle type information should travel to the set limiter (or stopper) number, that is, determines which secondary limiter function is activated. Set up multiple stop positions, and set corresponding sensors to identify the vehicle type, when the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com