Honeycomb core strip splicing device

A splicing device, honeycomb core technology, applied in the direction of connecting components, material gluing, mechanical equipment, etc., can solve the problems of poor adhesion of double-sided adhesive, low efficiency of gluing, broken honeycomb core, etc. High and efficient splicing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below through specific embodiments.

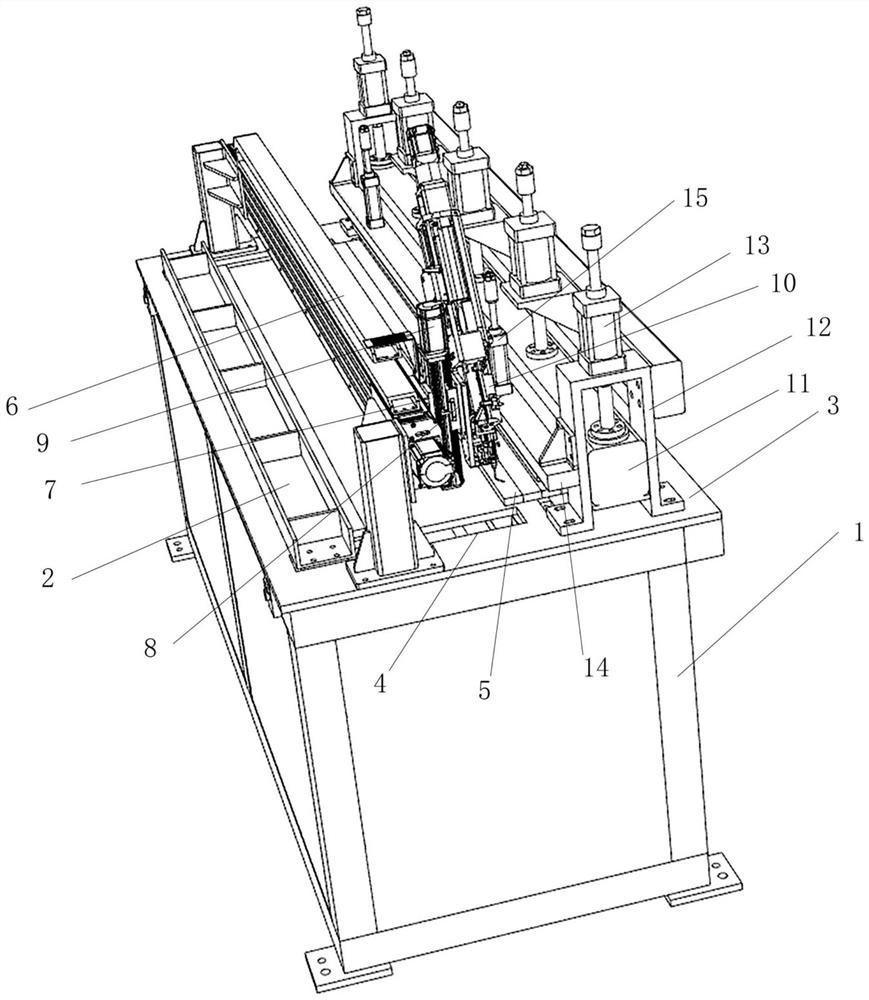

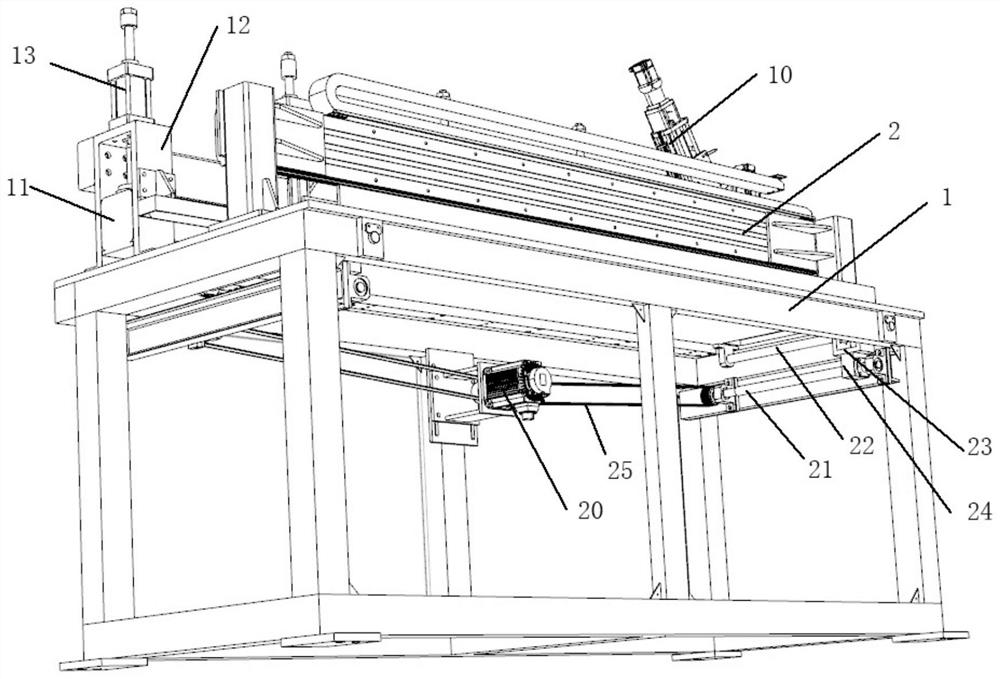

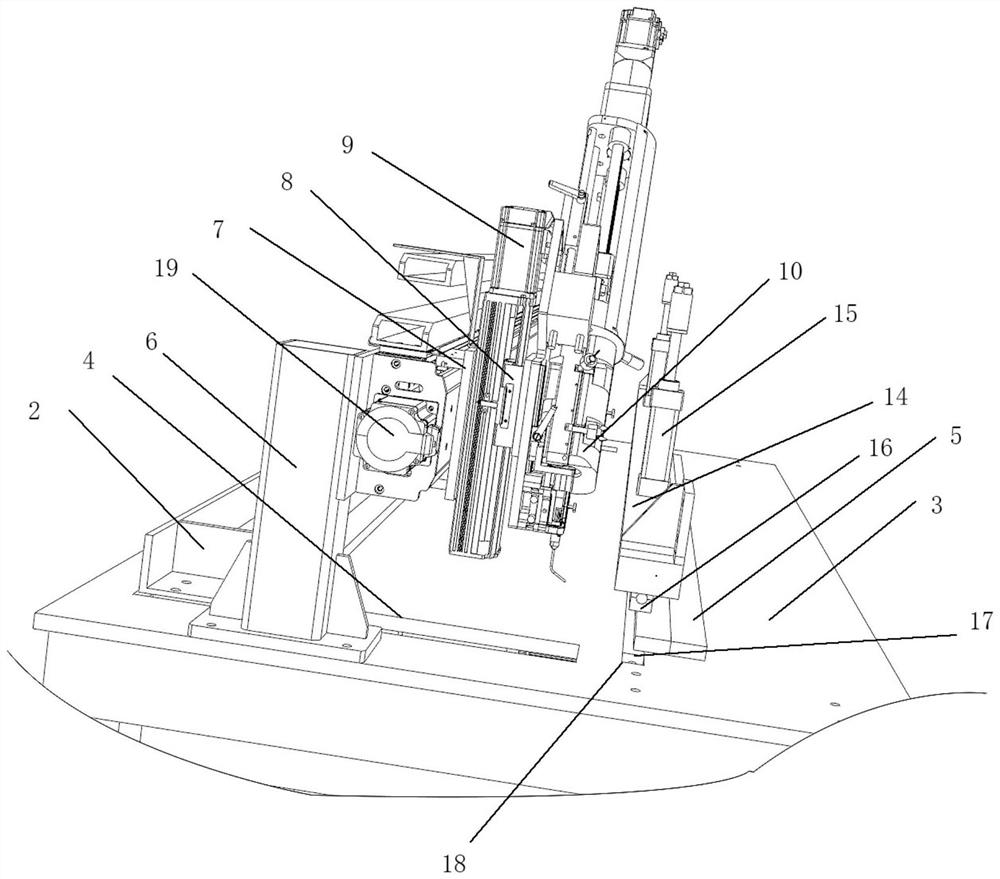

[0024] like figure 1 , figure 2 and image 3 As shown, a splicing device for honeycomb core strips 5 includes a frame 1, and a workbench 3 is arranged on the frame 1, and the workbench 3 is provided with a feeding station, a gluing station, and a heating station. Position and auxiliary pressure station, the extruded beam 2 is installed horizontally on the table 3, and the sliding direction of the extruded beam 2 is perpendicular to the length direction of the honeycomb core bar 5, and the extruded beam 2 is spliced by the power unit 20. The drive keeps the honeycomb core strips 5 on the feeding station in sequence at the gluing station, the heating station and the auxiliary pressing station.

[0025] Wherein, the extrusion beam 2 includes a body of the extrusion beam 2 arranged on the table top of the workbench 3 , two sliding seats 23 are fixedly connected to the body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com