A radiographic automatic detection device for girth welds of small cylinders

An automatic detection device and girth weld technology, applied in the field of X-ray detection, can solve the problems of no description or report, no collection of similar data at home and abroad, etc., to reduce tediousness and labor intensity, ensure process stability, Realize the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The following is a detailed description of the embodiments of the present invention: this embodiment is implemented on the premise of the technical solution of the present invention, and provides detailed implementation methods and specific operation processes. It should be noted that those skilled in the art can make several modifications and improvements without departing from the concept of the present invention, and these all belong to the protection scope of the present invention.

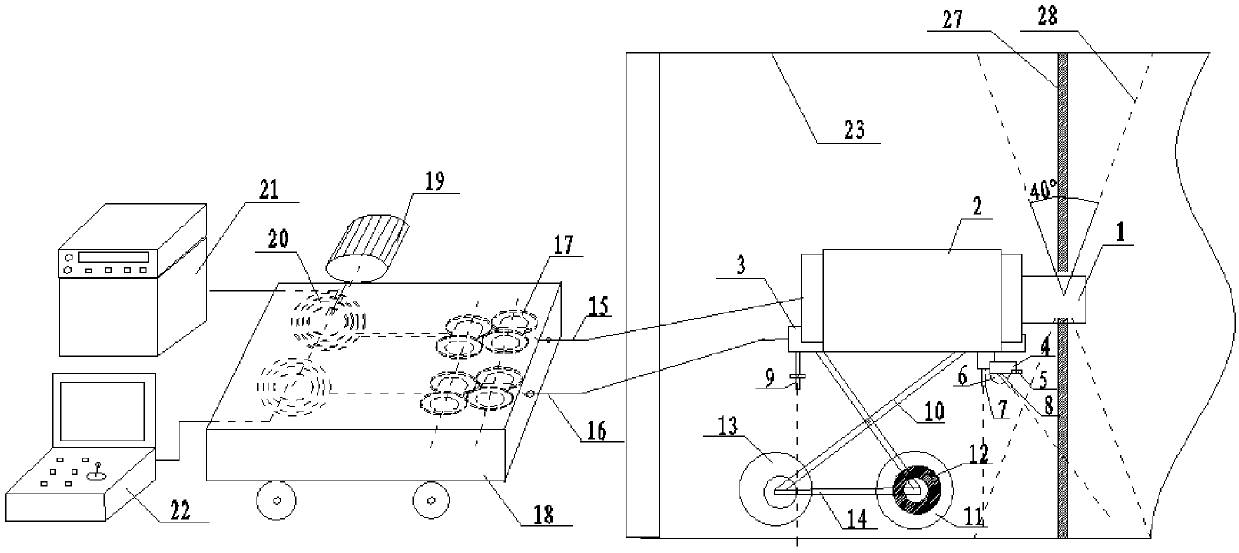

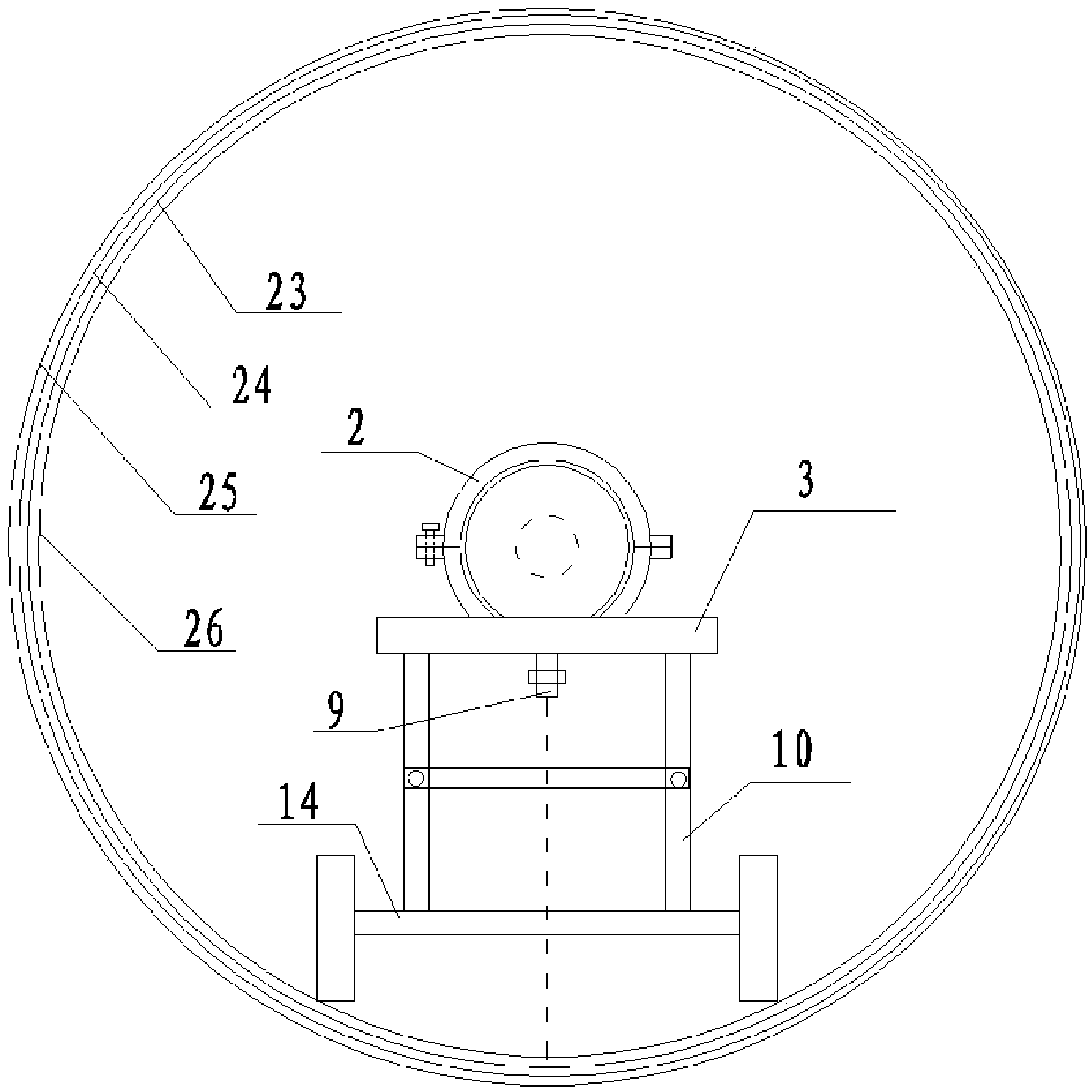

[0025] Please also see figure 1 and figure 2 .

[0026] Such as figure 1 As shown, a preferred embodiment of the present invention provides a small-scale cylinder girth weld automatic radiation detection device, including: a circumferential X-ray machine 1, a hoop 2, a lifting platform 3, a rotating head 4, a camera 5, a half Circular angle ruler 6, laser range finder 7, laser locator 8, "T" type laser range finder 9, telescopic hinge 10, front drive wheel 11, position encoder 12, r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com