Size scraping device for cloth production

A cloth and cloth guide roller technology is applied in the processing of textile materials, the configuration of equipment for processing textile materials, and the removal of liquid/gas/vapor by scraping. Transport and improve the effect of scraping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

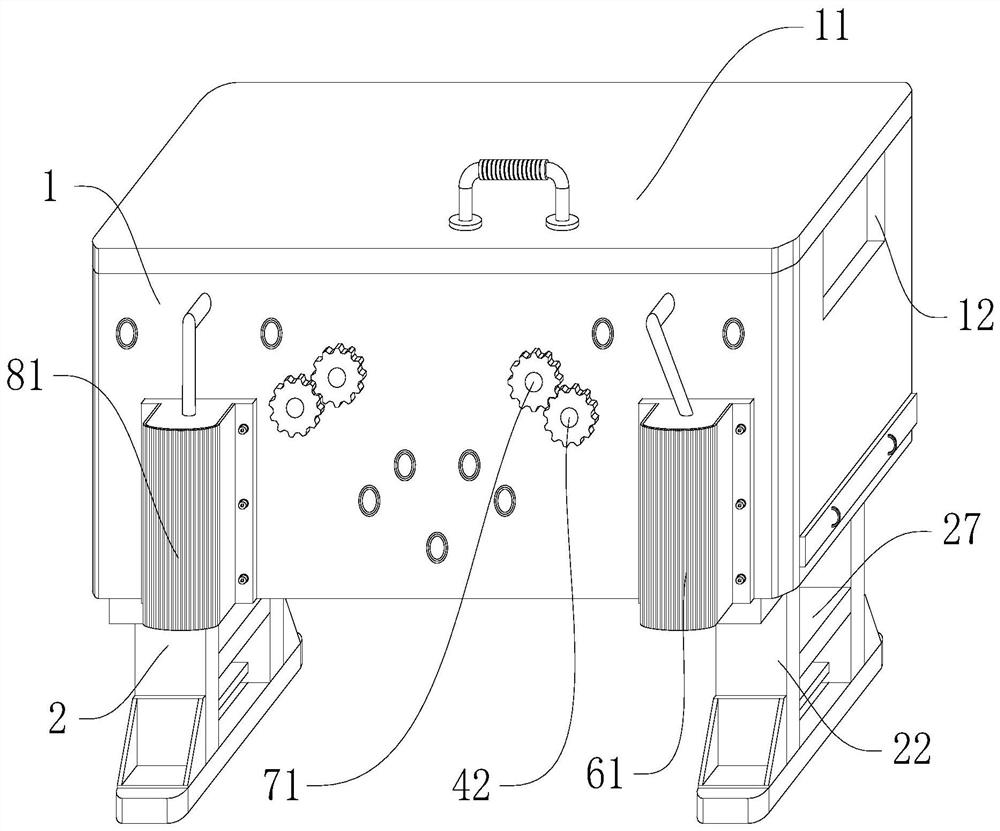

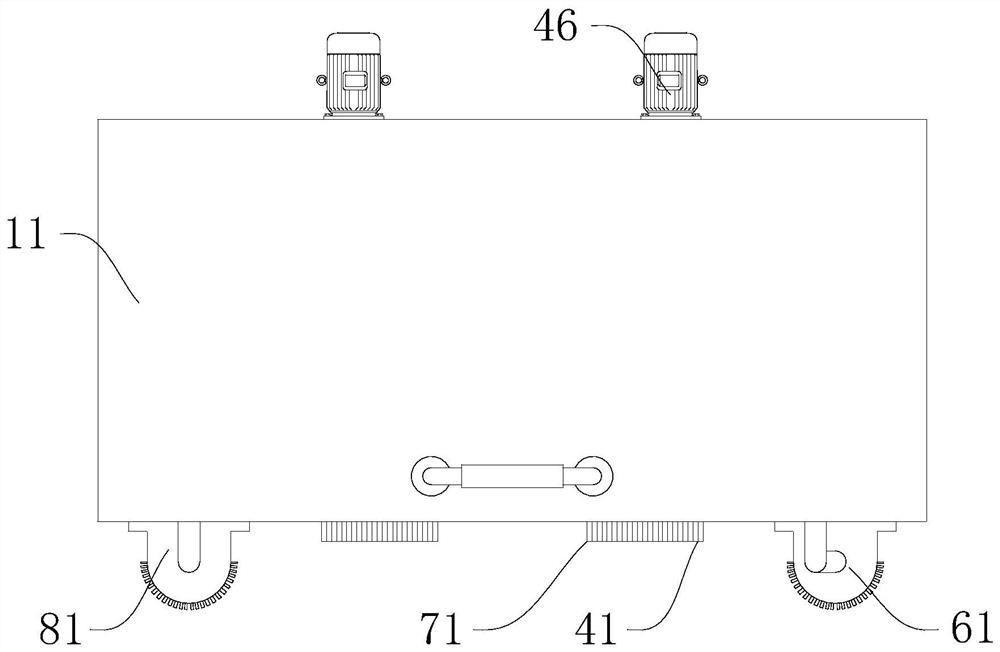

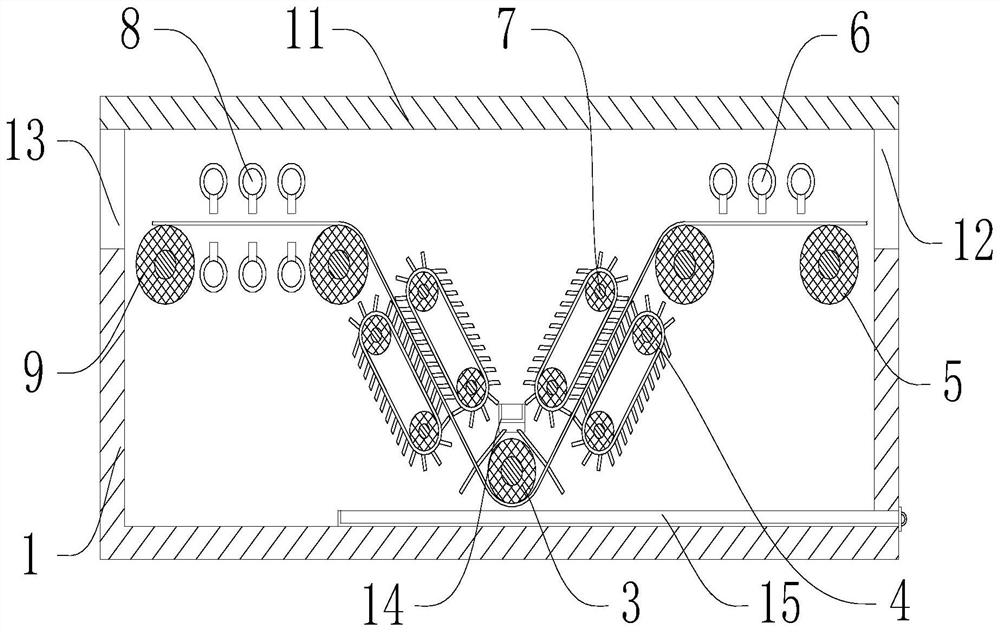

[0037] The specific embodiment, firstly, the adjusting screw rod 29 can be forwardly rotated, because the adjusting screw rod 29 is threadedly connected with the fixed plate 27, so the adjusting screw rod 29 rotates and moves downward at the same time, and then drives the moving plate 26 to move downward between the two supporting plates 22. Move, and then make the moving wheel 25 penetrate the square groove 24 and contact the ground, and lift the bottom plate 23, thereby using the moving wheel 25 to move the device to the required position, and then reversely turn the adjusting screw 29, so that the adjusting screw 29 moves upwards, Then drive the moving plate 26 to move upward, so that the moving wheel 25 returns to the inside of the square channel 24, and the bottom plate 23 is in contact with the ground, so that the device is placed stably, and then the two driving motors 46, the heater 61 and the refrigerator are connected. 81 circuit, then open the cover plate 11, then tr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com