Plastic paper printing machine

A technology for plastic paper and printing machines, applied in printing machines, rotary printing machines, general parts of printing machinery, etc., can solve the problems of inaccurate patterns, waste of raw materials, waste of manpower, etc., to achieve clear printing, reduce workload, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

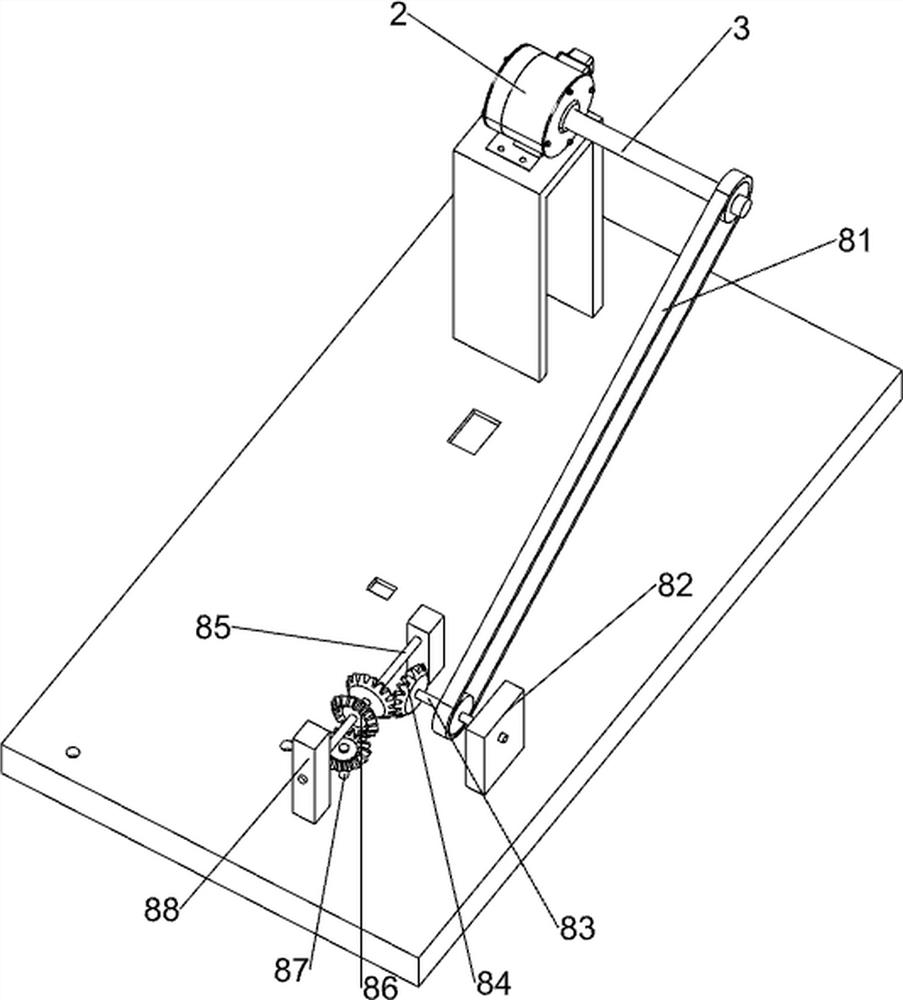

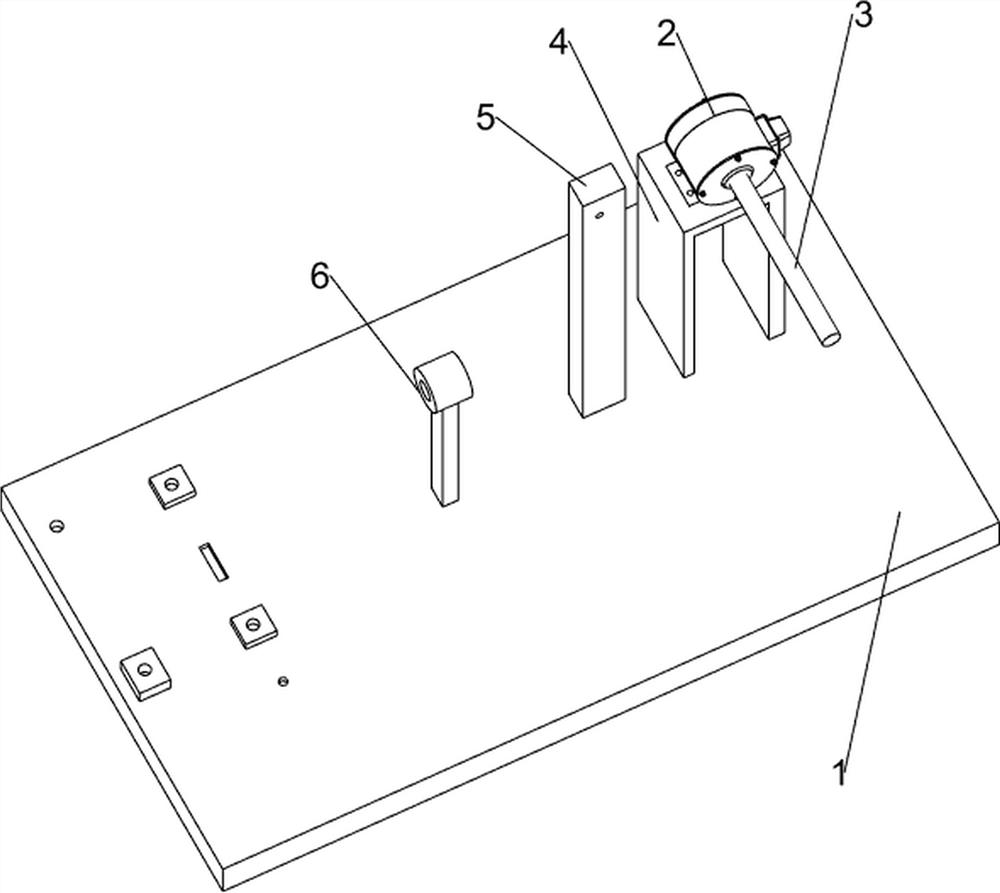

[0076] A plastic paper printing machine, such as figure 1 with figure 2 As shown, it includes a bottom plate 1, a motor 2, a transmission shaft 3, a first support 4, a second support 5, a third support 6, a reciprocating mechanism 7, a sovereign transmission mechanism 8 and a conveying mechanism 9. The first bracket 4 and the second bracket 5 are arranged on the top, the second bracket 5 is located in front of the first bracket 4, the motor 2 is installed on the first bracket 4, the transmission shaft 3 is arranged on the output shaft of the motor 2, and the upper middle of the bottom plate 1 A third support 6 is provided, a reciprocating mechanism 7 is provided on the transmission shaft 3, the second support 5 and the third support 6, and a sovereign transmission mechanism 8 is provided on the right side of the upper front part of the bottom plate 1 and the transmission shaft 3, and on the bottom plate 1 The left side of the front part is provided with a conveying mechanism...

Embodiment 2

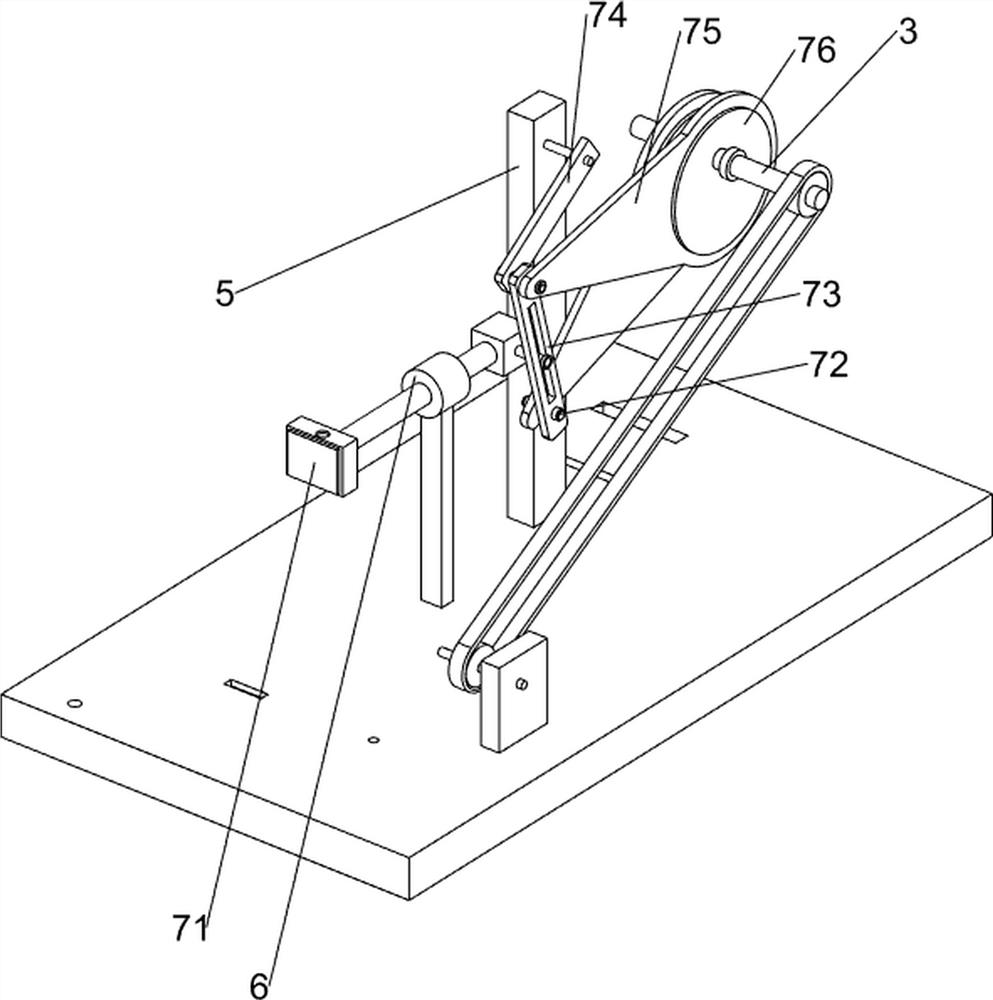

[0079] On the basis of Example 1, such as image 3 , Figure 4 with Figure 5 As shown, the reciprocating mechanism 7 includes a printing rod 71, a motion shaft 72, a sliding frame 73, a turret 74, a sector block 75 and a round wheel 76, and the third support 6 upper sliding type is provided with a printing rod 71, and the front of the printing rod 71 The upper part of the printing rod 71 is provided with a printing block, and the upper side of the printing rod 71 has a circular through hole, and the right side of the second support 5 is rotatably provided with a turret 74, and the left and right parts of the transmission shaft 3 are provided with a round wheel 76, and the round wheel 76 are all provided with fan-shaped block 75, between the fan-shaped block 75 of the right part and the turret 74, the rotating type is provided with motion shaft 72, and the rotation type in the middle part of motion shaft 72 is provided with sliding frame 73, and sliding frame 73 and printing ...

Embodiment 3

[0086] On the basis of Example 2, such as figure 1 , Image 6 , Figure 7 , Figure 8 , Figure 9 with Figure 10 Shown, also comprise clamping mechanism 10, supporting mechanism 11 and paint adding mechanism 12, the sixth rotating shaft 97 on the right side is provided with clamping mechanism 10, and base plate 1 upper front part is provided with supporting mechanism 11, and supporting mechanism 11 tops Located inside the conveyor belt 95 , the upper middle part of the bottom plate 1 is provided with a paint adding mechanism 12 , and the paint adding mechanism 12 is located in front of the third support 6 .

[0087] During the printing process, the clamping mechanism 10 clamps and fixes the plastic paper to make the printing position more accurate, the support mechanism 11 supports the conveyor belt 95 to make the printing clearer, and the pigment adding mechanism 12 adds pigment to the printing block on the printing rod 71 in time to make the printing block always Maint...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com