A track automatic intelligent three-dimensional storage system

A storage system and intelligent technology, applied in the stacking, transportation and packaging of objects, storage devices, etc., can solve the problems of inconvenient storage and use of pads alone, cumbersome use of three-dimensional warehouses, etc. The degree of automation and ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

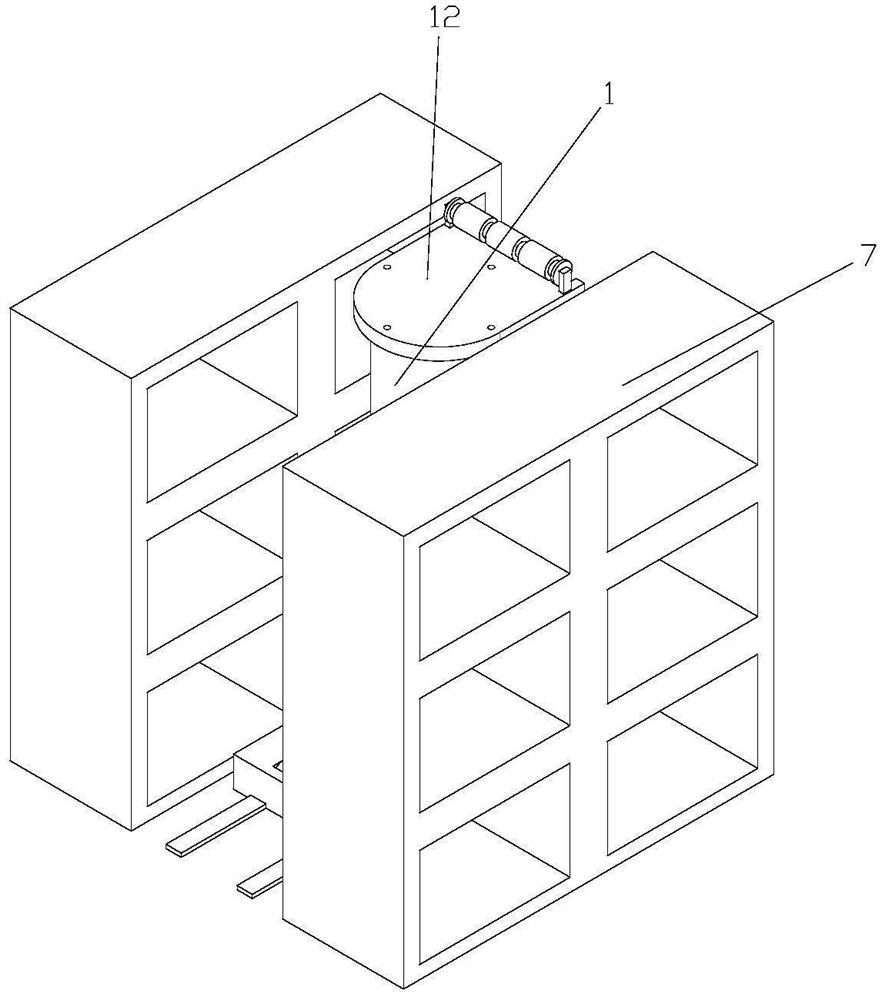

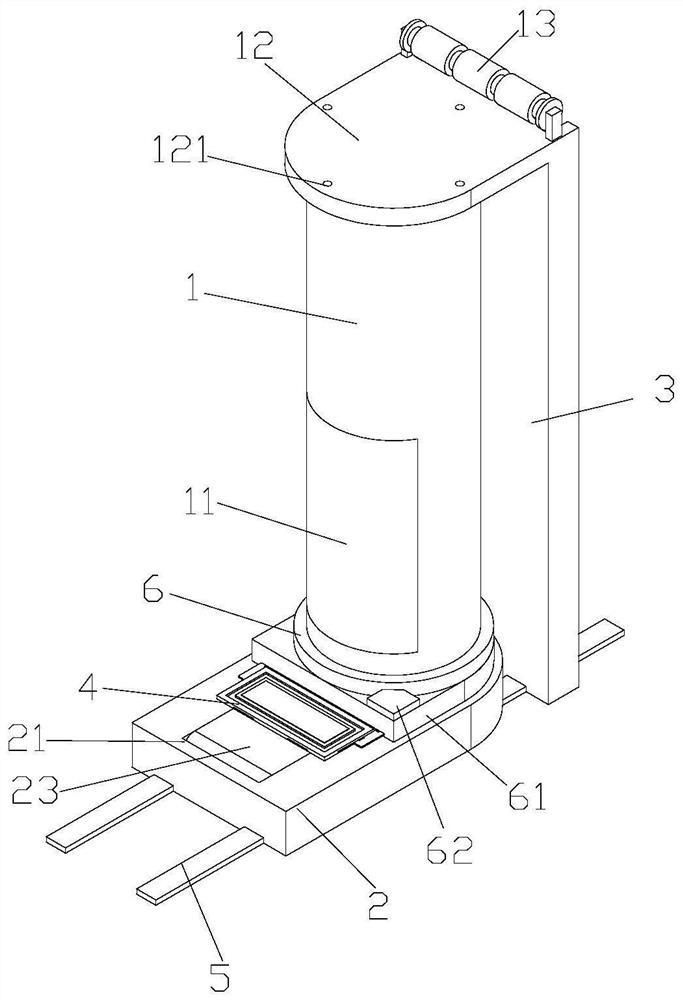

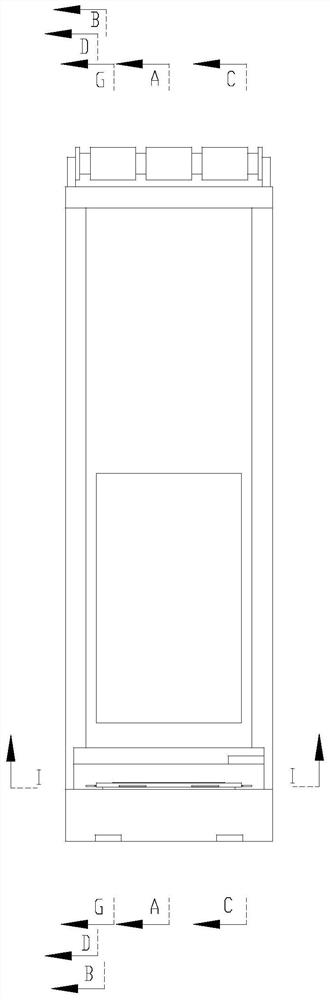

[0036] Such as Figure 1-20 As shown, a track automatic intelligent three-dimensional storage system includes a shelf 7 and a stacker located on one side of the shelf 7, and one side of the shelf 7 is provided with a guide rail 5 for guiding the stacker. The stacker includes a base 2 and a support column 1 arranged on the base 2, the support column 1 is covered with a movable ring 6, and the bottom of the movable ring 6 is rotatably connected with a mounting ring 61, and the mounting ring 61 There is a support plate 4 on it, and the support column 1 is provided with a first cavity 27 for storing the support plate 4; the support plate is placed on the base, and the goods are placed on the support plate to provide support for the goods through the support plate Under the setting of the support plate, the contact area with the goods is increased, thereby increasing the support effect on the goods and ensuring that the goods rise steadily under the action of the stacker; when the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com