Wall surface flatness detection device for building construction

A detection device, a technology for building construction, applied in the direction of mechanical roughness/irregularity measurement, etc., can solve the problems of damage to the wall, poor detection effect, low detection efficiency, etc., to improve the use effect, improve detection efficiency, detection full effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

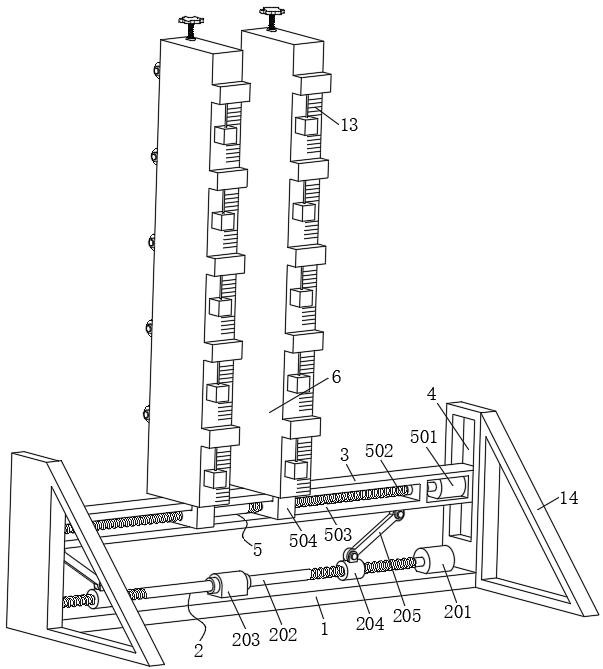

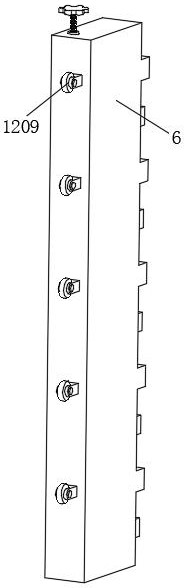

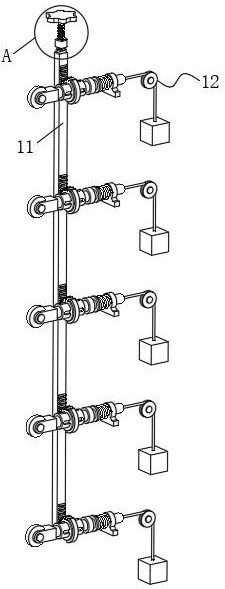

[0029] Such as Figure 1-7 As shown, the present invention provides a kind of wall flatness detection device for building construction, comprising U-shaped frame 1, movable plate 3 is movably connected with lifting mechanism 2 on U-shaped frame 1, and the two sides of movable plate 3 are respectively slidably connected In the limit chute 4 offered on the inner side wall of the U-shaped frame 1, a two-way moving mechanism 5 is fixed in the movable plate 3, and two casings 6 are connected on the two-way moving mechanism 5, and the top of the casing 6 is embedded with a screw. The sleeve 7, and the inner screw drive of the screw sleeve 7 is connected with a screw 8, and the end of the screw 8 outside the shell 6 is fixedly connected with a turning handle 9, and the end of the screw 8 inside the shell 6 passes through the first bearing sleeve 10 and the adjusting tooth plate 11 Rotationally connected, the adjusting tooth plate 11 is limited and slidingly connected in the housing 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com