A simple test device for the sealing performance and friction state of the dynamic sealing pair on the end face

A state test and dynamic sealing technology, which is applied in the direction of measuring devices, liquid tightness measurement using liquid/vacuum degree, testing of mechanical parts, etc., can solve the problem of not being able to fully verify the sealing performance and friction performance of the dynamic sealing pair, and the friction torque is small Work efficiency, low efficiency and other problems, to achieve the effect of high promotion and application value, convenient operation, simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

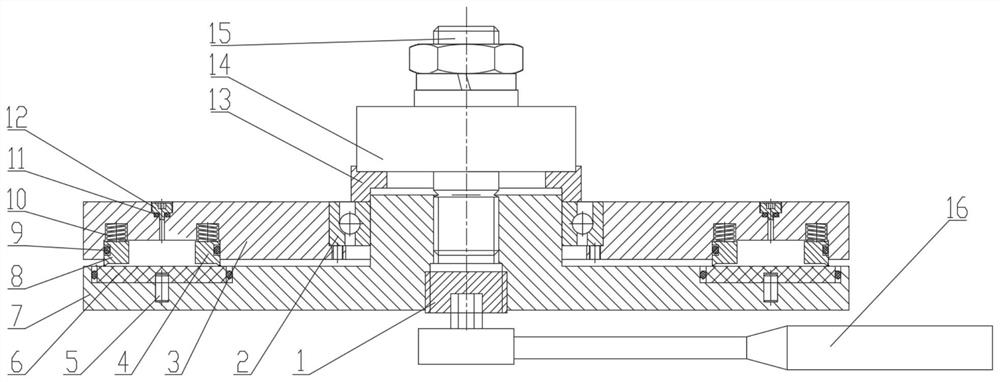

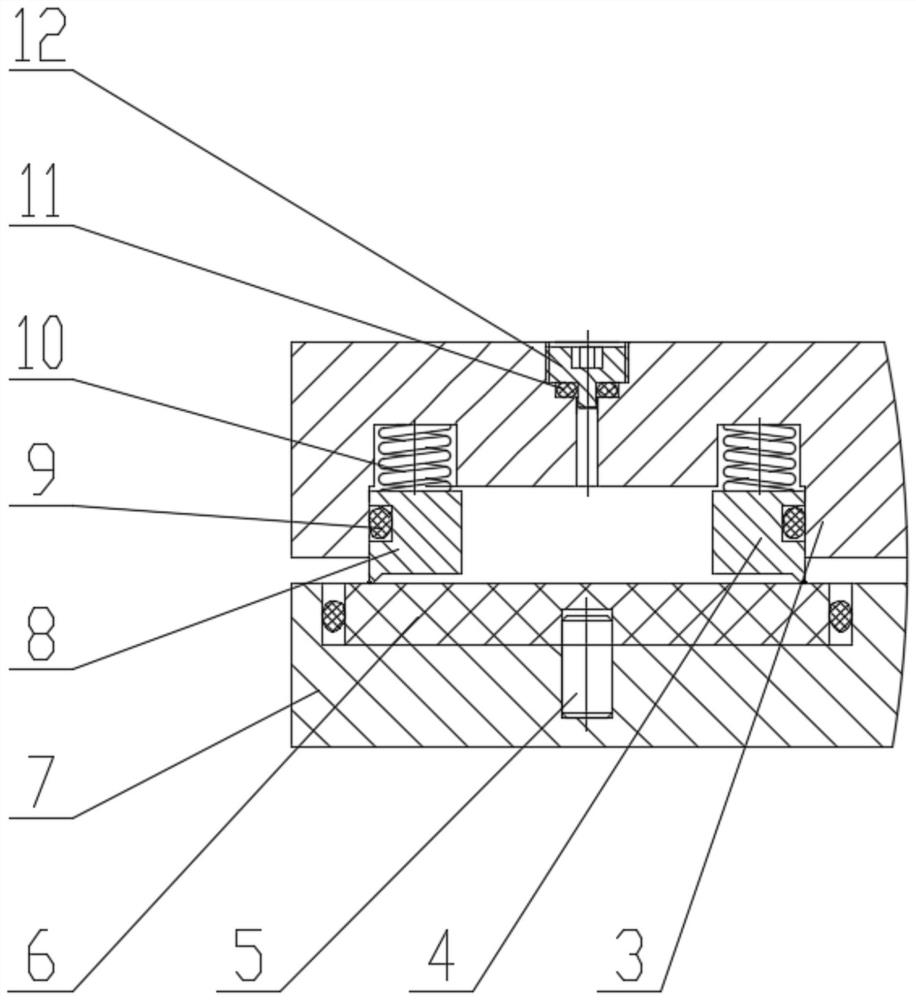

[0022] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 and figure 2 As shown, the simple end face dynamic seal pair sealing performance and friction state testing device in this embodiment includes an upper flange 3, an installation hole is opened in the middle of the upper flange 3, and a concave cavity is provided on the lower surface of the upper flange 3. The two sides of the concave cavity are respectively clamped with an inner metal sliding ring 4 and an outer metal sliding ring 8. A series of cylindrical holes are evenly distributed on the upper surface of the concave cavity along the circumferential direction. Compression springs 10 are installed in the cylindrical holes, and each The compression spring 10 is in contact with the inner metal sliding ring 4 and the outer metal sliding ring 8; it also includes a lower flange 7, the section of the lower flange 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com