Automatic stringing equipment for power pole wires

A power line pole and wiring technology, which is applied to overhead lines/cable equipment, etc., can solve the problems of overall operation trouble, physical effort, and speed up the progress of power line pole wiring, so as to achieve the effect of improving efficiency and safety, and saving time and effort in operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

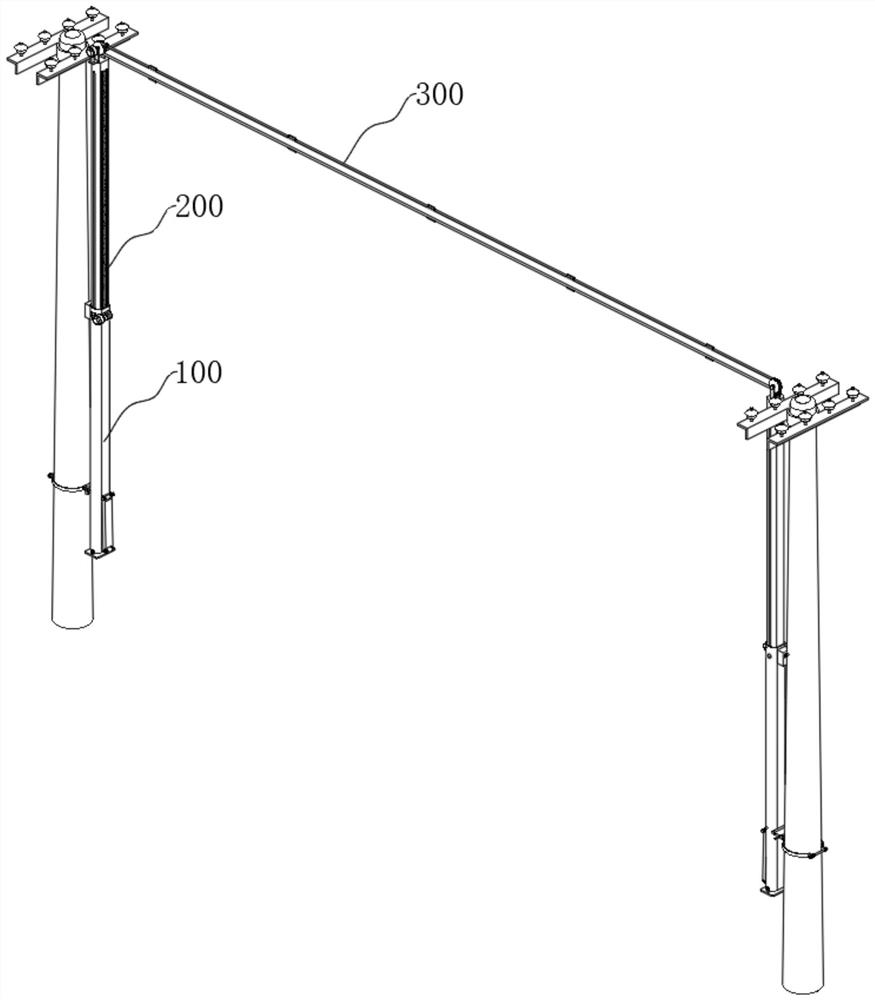

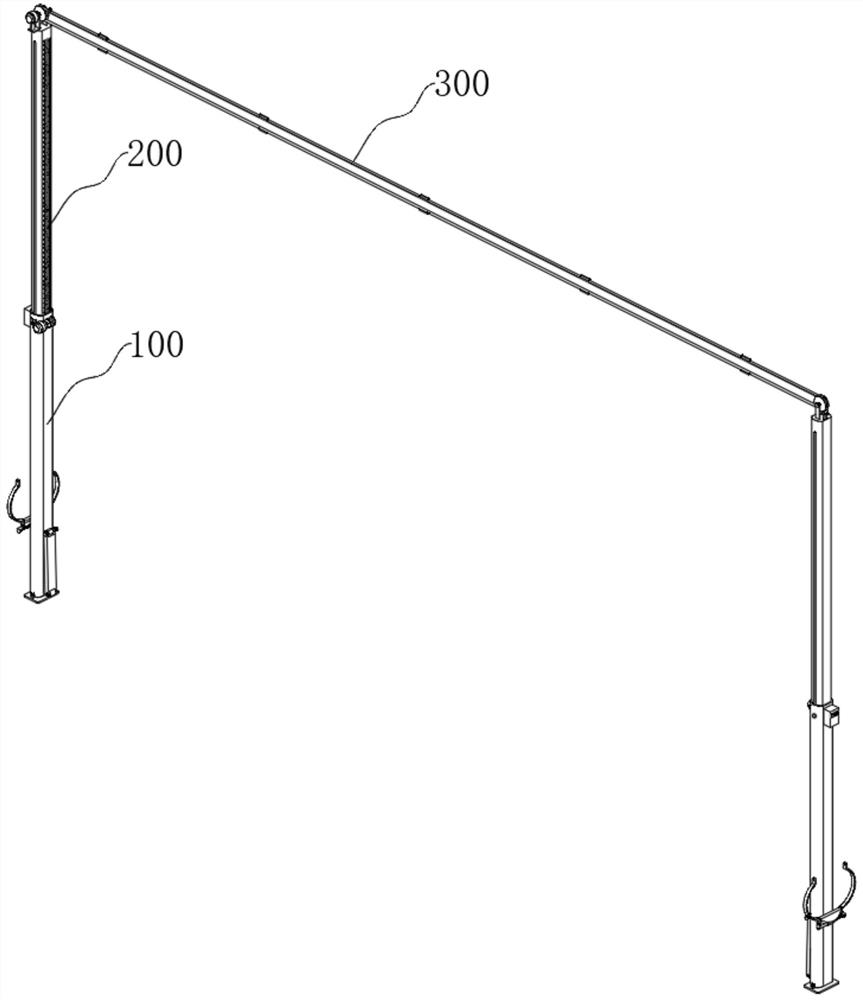

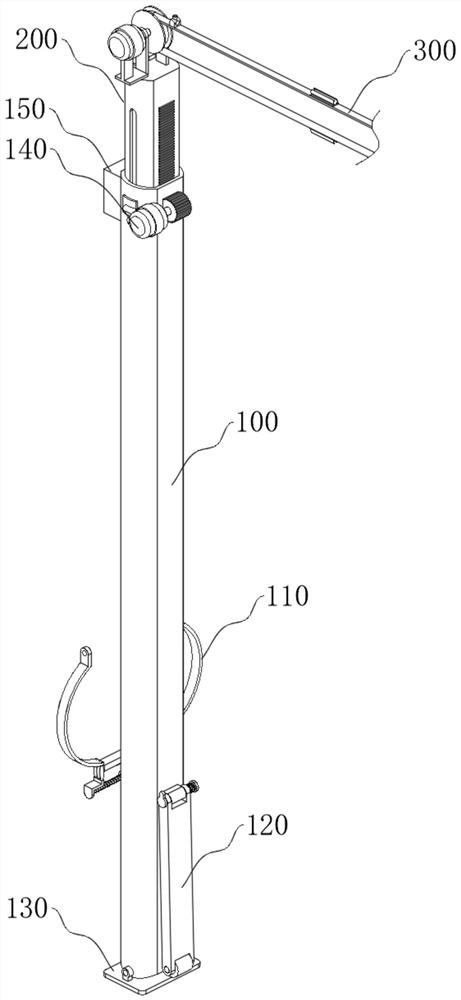

[0048] see Figure 1 to Figure 15 As shown, the present invention provides an automatic wire stringing equipment for electric power poles, including a pair of wire pipes 100 fixed between adjacent power poles, a wire laying pipe 200 and a wire laying pipe 200 for lifting wires inside the wire pipe 100 The top of the laying pipe 200 is provided with a stringing mechanism 300 for conveying electric wires. The wire-laying pipe 100 is in the shape of a cylinder with two flat sides in the radial direction. This structure is easy to form a limiting effect, so that the wire-laying pipe 200 placed therein will not rotate. A binding mechanism 110 for clamping the power pole is provided on the side plane of the lower half of the line pipe 100, so that the line pipe 100 can be stably placed on the ground to ensure the stability of the line without manual support. The binding mechanism 110 is divided into a horizontal folded state and a vertical unfolded state. When in use, turn it to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com