Dried kelp having reduced iodine content, and method for producing dried kelp

A manufacturing method and technology of iodine content, which are applied in the fields of food drying, food science, and application, can solve the problems of complicated processing, high manufacturing cost, poor industrial practicability, etc., and achieve the effect of eliminating the drying process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] In this disclosure, "per unit dry weight" refers to the iodine content in a dry product that contains no moisture removed by drying treatment, and "per unit absolute dry weight" refers to the iodine content obtained by heating and drying at 105°C under normal pressure. The moisture content in the leaf is used to convert the moisture content to the value of the iodine content at 0%.

[0060] Hereinafter, the present invention will be described with examples.

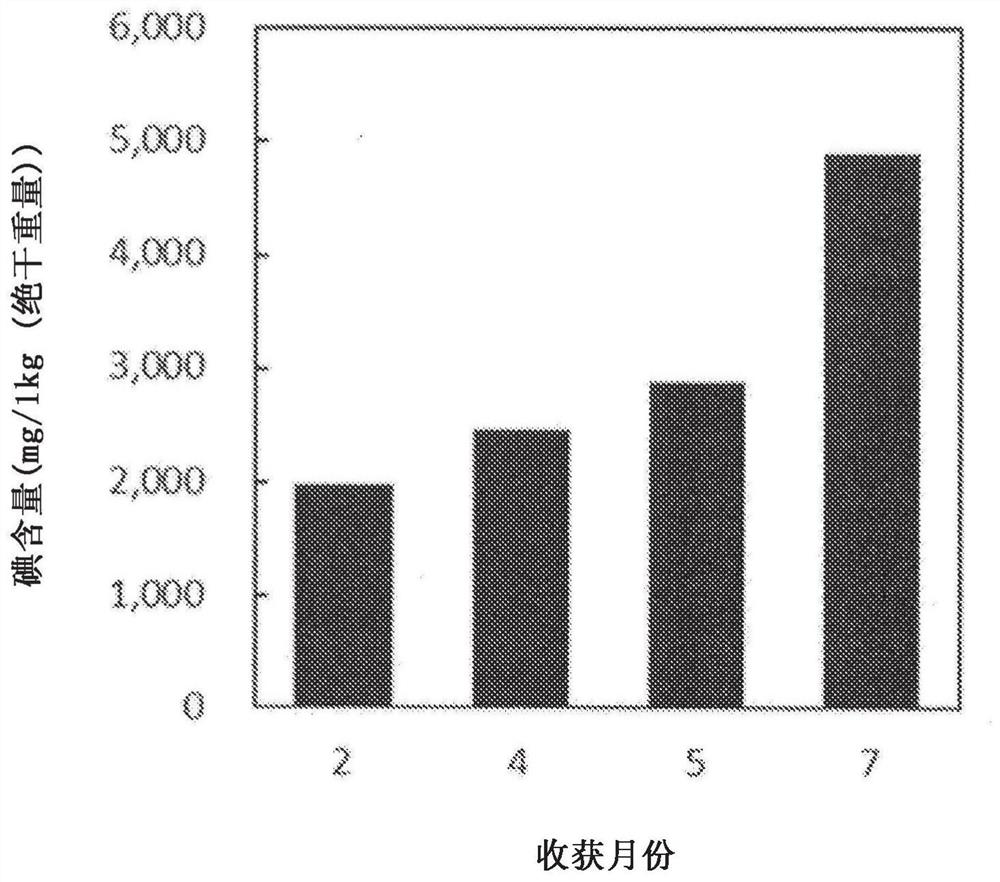

[0061] According to previous research by the present inventors, it is known that the iodine content contained in the leaves of kelp (kelp) harvested in spring is less than that contained in the leaves of kelp harvested in summer, but the details over time are not known. situation (Non-Patent Document 6). Therefore, for the first time, the iodine content contained in fast-growing Japanese kelp (maconbu) harvested in the Hakodate area from February to July in 2017 (Heisei 29) was studied.

[0062] The iodine conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com