Pretreatment method for flavored kelp processing

A pretreatment, kelp technology, applied in microorganism-based methods, biochemical equipment and methods, food ingredients as odor modifiers, etc. problem, to achieve the effect of emerald green color, safe and hygienic process, and obvious effect of removing fishy smell

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

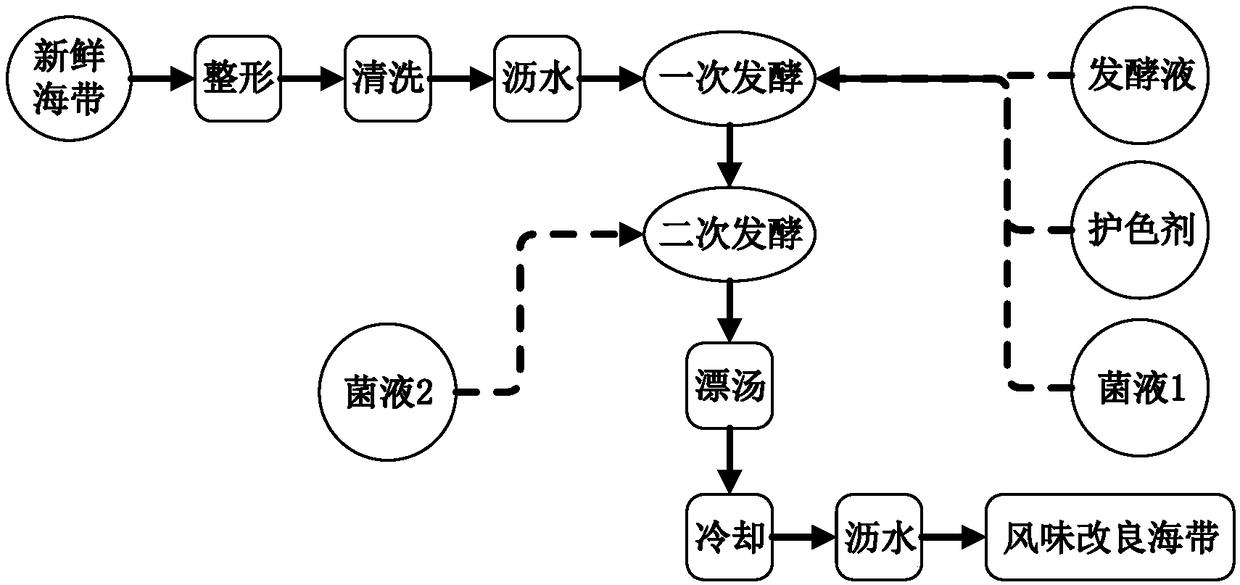

Image

Examples

preparation example Construction

[0030] The preparation method of dry bread yeast activation liquid in the embodiment of the present invention is as follows:

[0031] Salt, glucose, and water were mixed and dissolved at a ratio of 0.1:0.25:100, sterilized at 121°C for 20 minutes, and then 2wt% Angel active dry yeast powder was added according to the quality of the water, sealed, shaken, and activated by magnetic stirring in a constant temperature water bath at 28°C for 30 minutes. Concentration diluted to 10 6 cfu / mL, stored in a refrigerator at 4°C, and used on the same day.

[0032] The preparation method of Streptococcus thermophilus and Lactobacillus bulgaricus activation solution is as follows: the ampoule tube of freeze-dried Streptococcus thermophilus powder or Lactobacillus bulgaricus powder is broken with tweezers, absorb 0.5mL of sterilized M17 broth medium to dissolve the bacteria powder, and then inoculate Put it into M17 broth medium, shake well, cultivate at 37°C until clearly visible colonies ...

Embodiment 1

[0034] (1) Cut the fresh kelp in the young and tender stage into long strips, wash it with clean water for 1.5 minutes to remove sediment and sundries, and then drain;

[0035] (2) Mix the drained long strips of kelp and the fermentation broth in a mass ratio of 1:3, put them under ultraviolet light for 30 minutes, and then insert 3 wt% of bread dry yeast activation liquid with reference to the quality of kelp, seal it, and store it at 28°C, 140r / min shaker fermentation. The above fermented liquid is mixed with glucose and color-protecting agent green tea extract at a ratio of 1:0.09:100; the color-protecting agent is mixed with EDTA-2Na and zinc acetate at a ratio of 2:1; the green tea extract is brewed at a tea-to-water ratio of 1:60 , leaching at 85°C for 10 minutes;

[0036] (3) After 2 hours of yeast fermentation, the seal was opened, and 9 wt% lactic acid bacteria activation solution was added according to the mass of kelp, sealed, and fermented on a shaking table at 37...

Embodiment 2

[0039](1) Cut the fresh kelp in the young and tender stage into long strips, wash it with clean water for 1 minute to remove sediment and sundries, and then drain;

[0040] (2) Mix the drained long strips of kelp with the fermentation broth in a mass ratio of 1:2, put them under ultraviolet light for sterilization for 30 minutes, add 5wt% bread dry yeast activation solution with reference to the quality of kelp, seal it, and store it at 28°C, 160r / min shaker fermentation. The above fermented liquid is mixed with glucose and color-protecting agent green tea extract at a ratio of 0.5:0.04:100; the color-protecting agent is mixed with EDTA-2Na and zinc acetate at a ratio of 1:1; the green tea extract is brewed at a tea-to-water ratio of 1:50 , leaching at 85°C for 8 minutes;

[0041] (3) After 0.5 h of yeast fermentation, the seal was opened, and 6 wt% lactic acid bacteria activation solution was added according to the mass of kelp, sealed, and fermented on a shaking table at 37...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com