Electroplating oiling device

An oiling device and oiling technology are applied to the device and coating of the surface coating liquid, which can solve the problems of difficult to identify the replacement nodes and lower oil quality, and achieve convenient maintenance, waste reduction, and overall structure compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention will be further described in detail below in conjunction with the drawings.

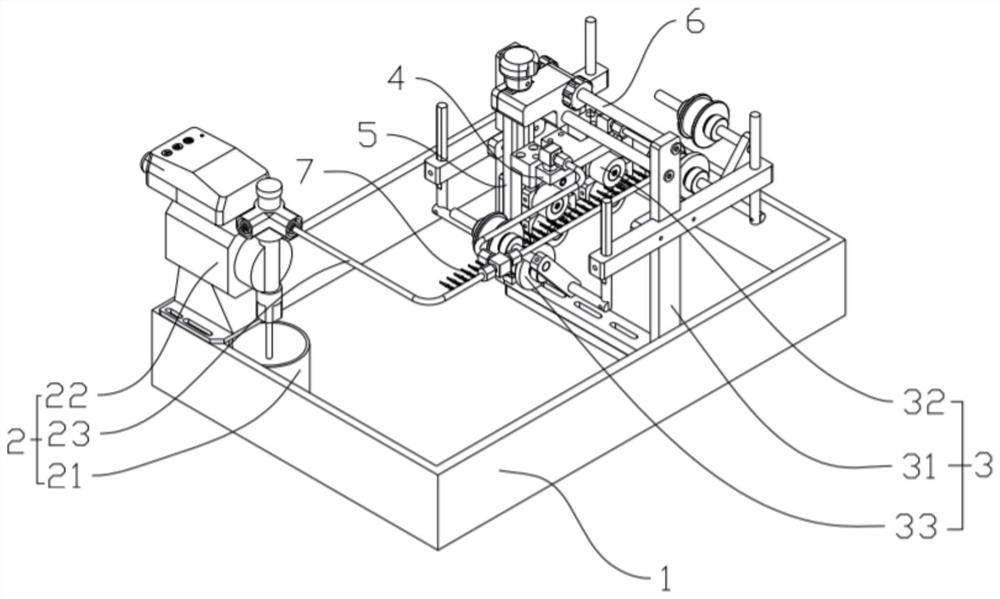

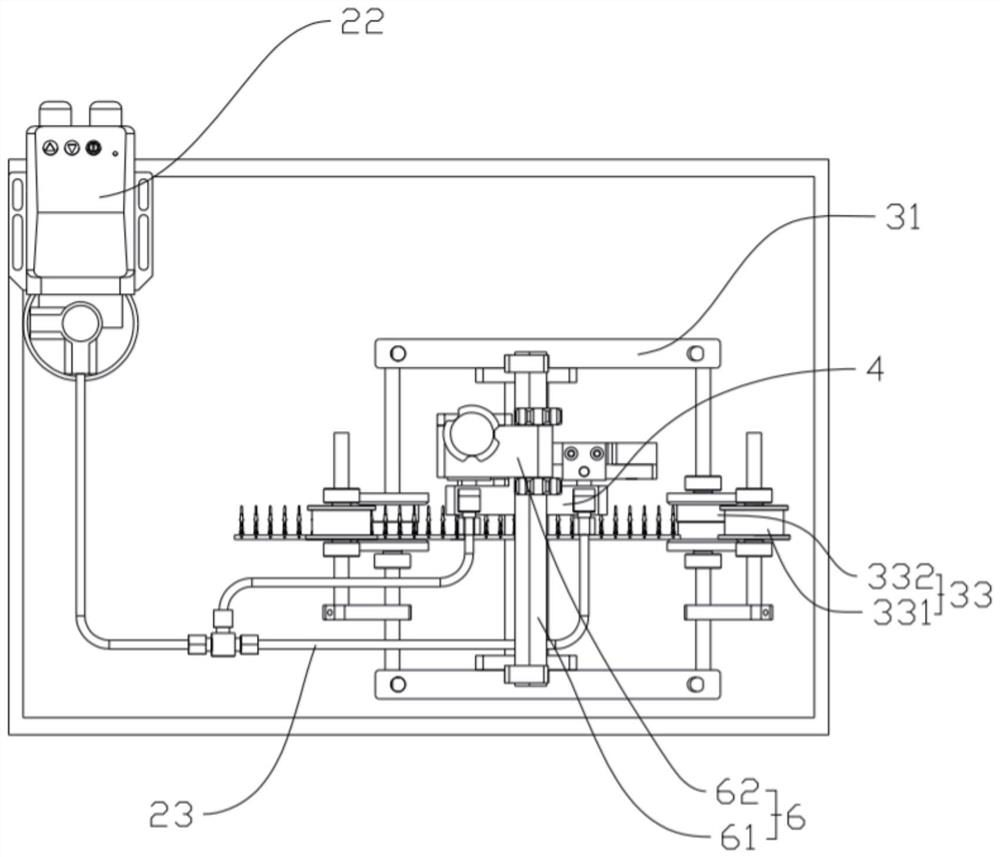

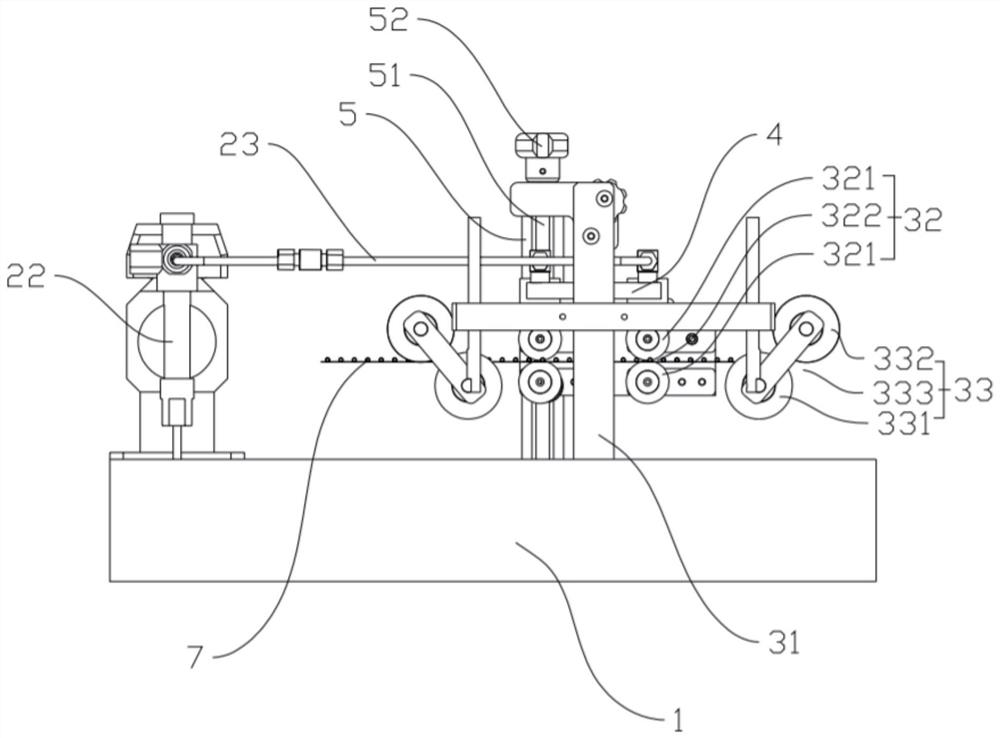

[0032]Such asFigure 1 to Figure 5As shown, an electroplating oiling device includes a tray, an oil supply component and an oil application component are arranged in the tray, and the oil supply component includes an oil cup for storing oil and a quantitative pump for supplying oil And a liquid supply pipe connecting the quantitative pump and the oil application assembly; the oil application assembly includes a base arranged in the tray, a guide wheel set and an oil application wheel set on the base, and the guide wheel set is arranged at the On both sides of the oiling wheel set, the oiling wheel set includes two oppositely arranged rollers and an oil supply block located above the rollers. An oiling gap through which the supply belt passes is formed between the two rollers. The roller is made of porous elastic material, and the liquid supply pipe is connected with the oil supply b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap