Cleaning device applied to production of chip wafers

A technology for cleaning devices and wafers, which is applied to cleaning methods using liquids, cleaning methods and utensils, static electricity and other directions, which can solve the problems of large size limitations of chips, insufficient fixation, and separation from metal stencils, etc., to improve the cleaning work. Efficiency, the effect of preventing damage to the chip

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

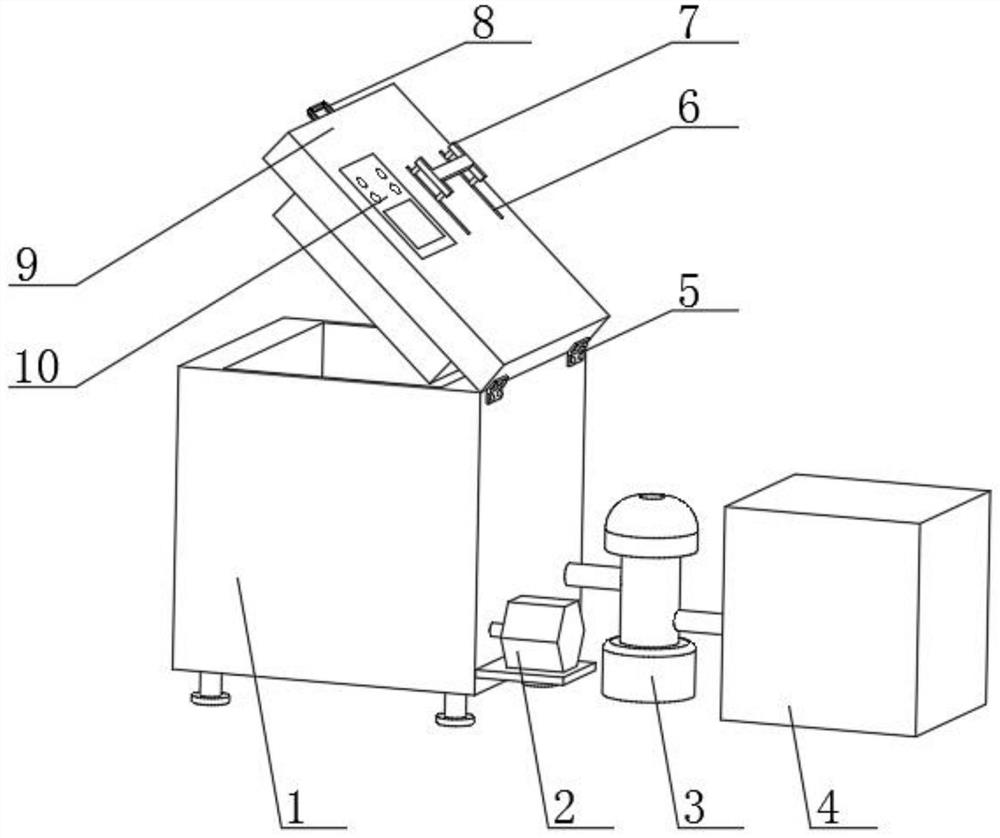

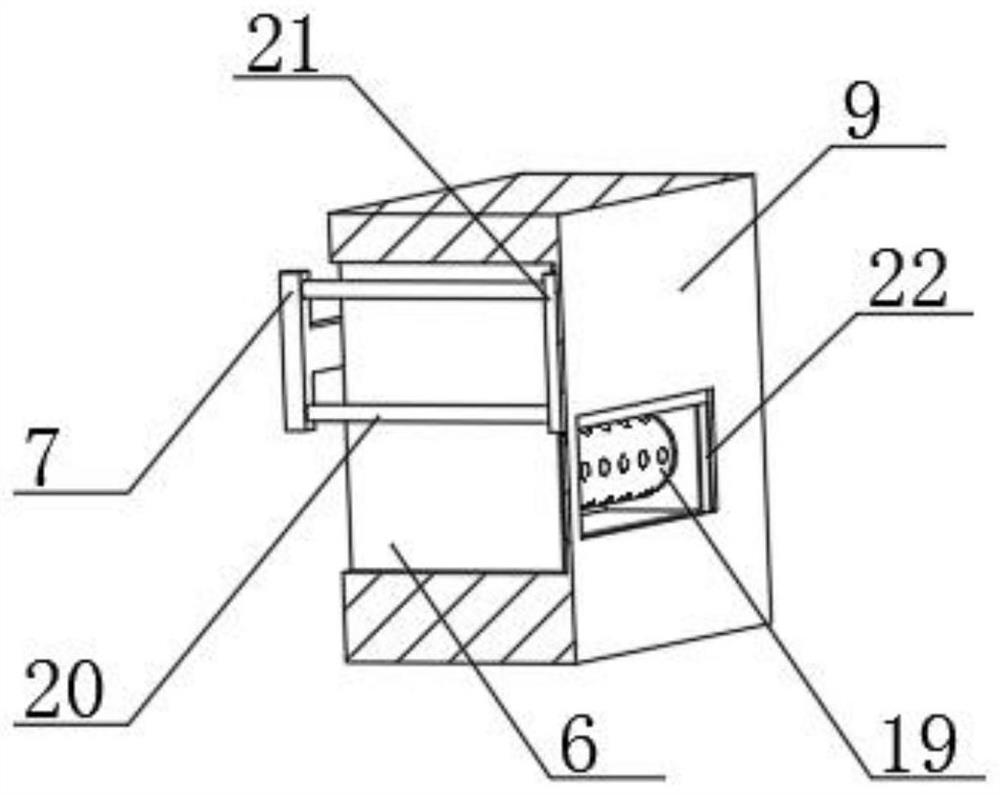

[0025] like figure 1 , 2 As shown in . and 3, a cleaning device for chip wafer production includes a device main body 1, an air pump 2 is arranged on the outer surface of the side end of the device main body 1, and a water pump 3 is arranged on the side end of the air pump 2. The model of the water pump 3 is WQ, the outer surface of the side end of the water pump 3 is provided with a cleaning liquid tank 4, the outer surface of the upper end of the device main body 1 is provided with a cover plate 9, the connection between the device main body 1 and the cover plate 9 is provided with a hinge 5, and the front end of the cover plate 9 The outer surface is provided with a handle 8, the upper outer surface of the cover plate 9 is embedded with a control panel 10, the side end of the control panel 10 is provided with a No. 1 groove 6, the upper end of the No. 1 groove 6 is provided with a limit frame 7, and the The lower end is fixedly installed with a fixed plate, and the side en...

Embodiment 2

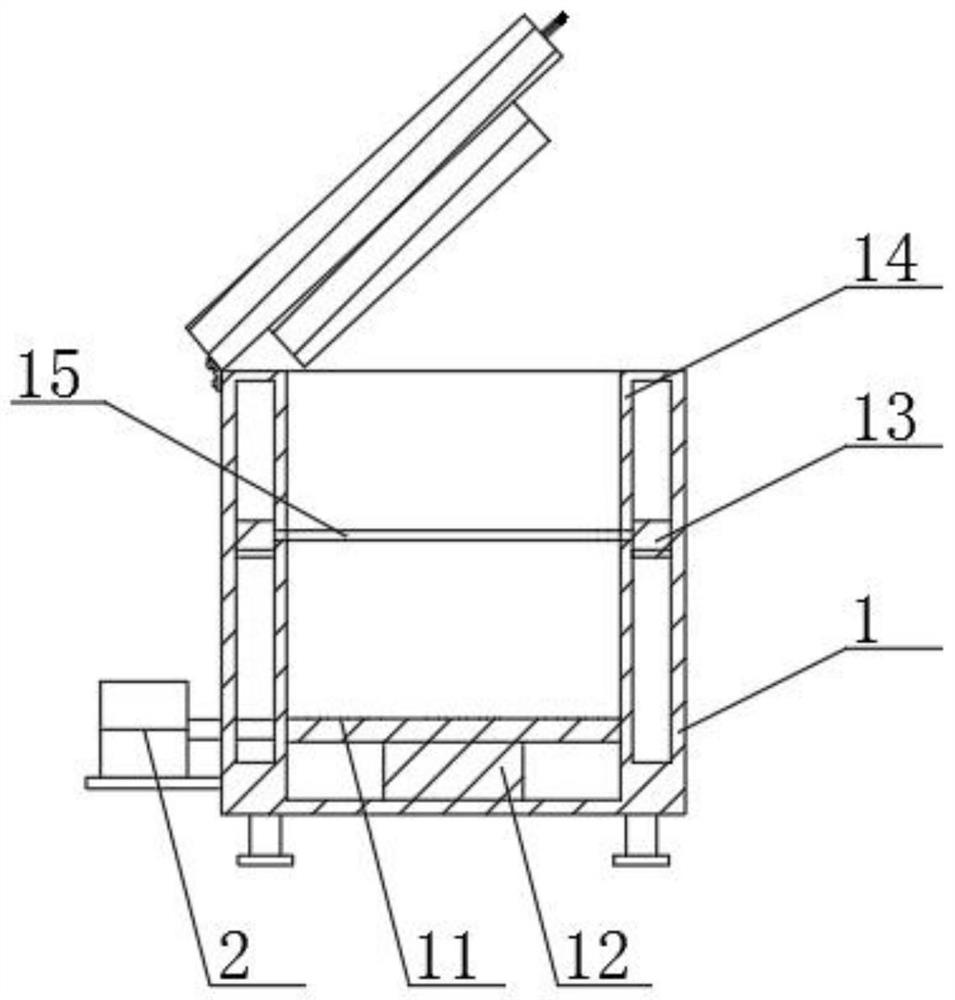

[0027] On the basis of Example 1, as figure 1 , 4 , 5, the number of motors 13 is two groups, and they are symmetrically arranged. The lower end of the motor 13 is fixedly equipped with a fixed plate, the fixed plate is embedded in the inner side of the partition plate 14 and the device main body 1, and the inner side of the metal mesh plate 15 is fixed. A connecting shaft is installed, the left and right ends of the connecting shaft run through the partition 14, and are fixedly embedded in the inner side of the motor 13, and the upper end of the air intake plate 11 is provided with several air holes, which are arranged in a rectangular array and arranged symmetrically The motor 13 can drive the metal mesh plate 15 to rotate through the connecting shaft. The metal mesh plate 15 drives the chip wafer in the cleaning liquid to rotate and clean, so as to improve the cleaning efficiency. The upper end of the metal mesh plate 15 is provided with a fixed rod 16, and the fixed rod T...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap