Turnover adjusting device for electromechanical machining

An adjustment device, electromechanical technology, applied in the direction of auxiliary devices, metal processing, metal processing equipment, etc., can solve the problems of inability to achieve integration, increase manufacturing costs, and reduce practicability, and achieve simple structure, reduce manufacturing costs, and improve stability sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

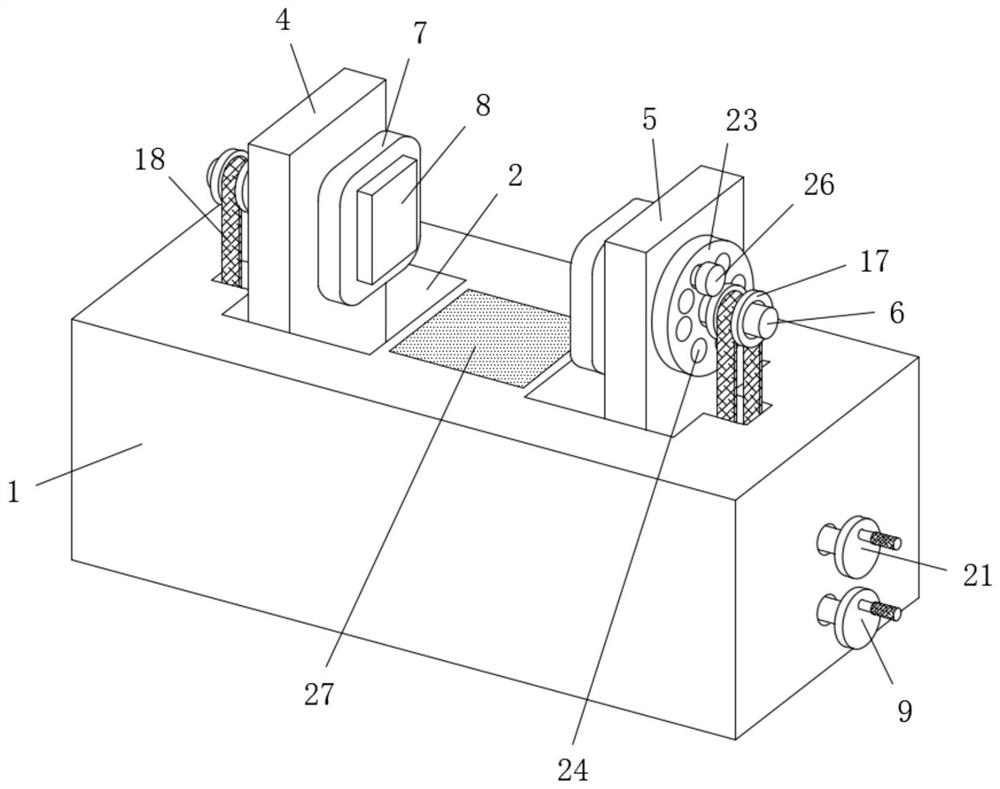

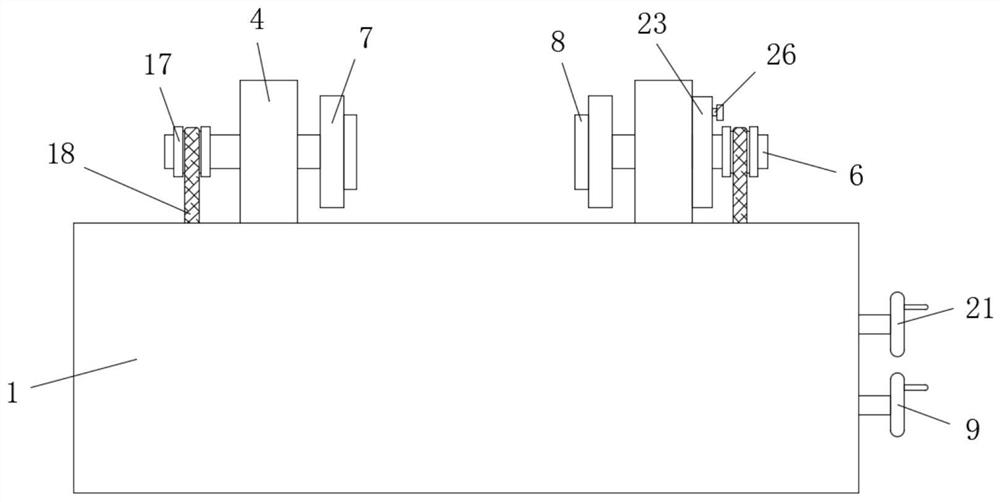

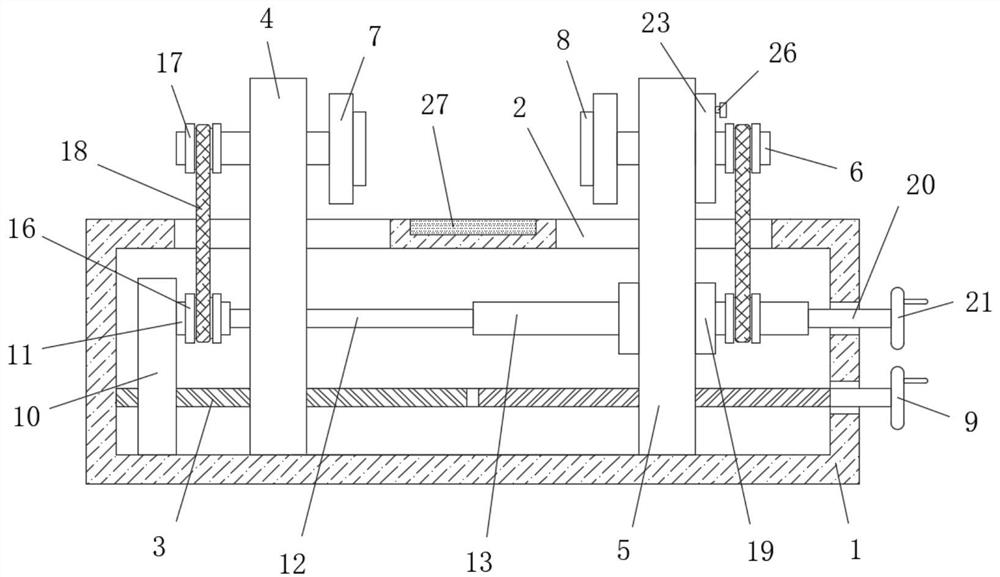

[0030] refer to Figure 1-7 , a flip adjustment device for electromechanical processing, including a base 1, and the base 1 is a hollow structure, two moving holes 2 are symmetrically opened on the top of the base 1, and the two moving holes 2 are connected with the inside of the base 1, and the base The internal rotation of 1 is connected with a screw rod 3, and the screw rod 3 is respectively threaded with a first nut plate 4 and a second nut plate 5, and the first nut plate 4 and the second nut plate 5 are arranged symmetrically, and the first nut plate 4 and the bottom of the second nut plate 5 are respectively slidingly connected with the bottom inner wall of the base 1, and one side of the first nut plate 4 and the second nut plate 5 respectively pass through two moving holes 2 and both extend to the top of the base 1. The top of one side of the nut plate 4 and the second nut plate 5 that are close to each other is connected with a first rotating rod 6 for rotation, and ...

Embodiment 2

[0032] Further improvement on the basis of Embodiment 1: The screw rod 3 is symmetrically provided with two sections of reverse threads, and the first nut plate 4 and the second nut plate 5 are respectively located on the two sections of reverse threads. When the screw rod 3 rotates, The first nut plate 4 and the second nut plate 5 can be moved relative to each other through two sections of reverse threads, and the end of the screw rod 3 close to the second nut plate 5 runs through one side of the base 1 and is fixedly connected with the first turntable 9, the third The end of the rotating rod 20 away from the rotating cylinder 13 runs through the side of the base 1 and is fixedly connected with the second turntable 21, and the side of the first turntable 9 and the second turntable 21 far away from the base 1 is fixedly connected with a rocker. The first rotating disk 9 and the second rotating disk 21 can drive the screw rod 3 and the third rotating rod 20 to rotate respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com