An automatic plastering machine for the upper surface of wall tiles

A wall brick, automatic technology, applied in the processing of building materials, construction, building structure, etc., can solve the problems of mortar solidification, poor effect, easy to solidify, etc., to achieve good plastering effect, compact structure, and convenient adjustment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

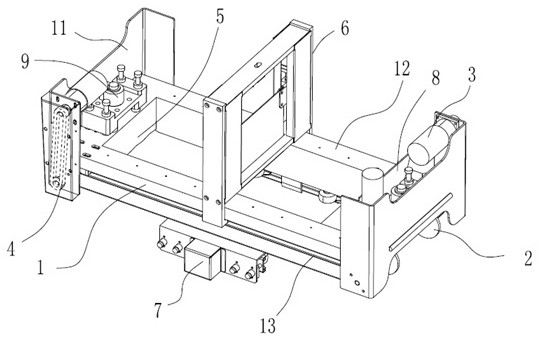

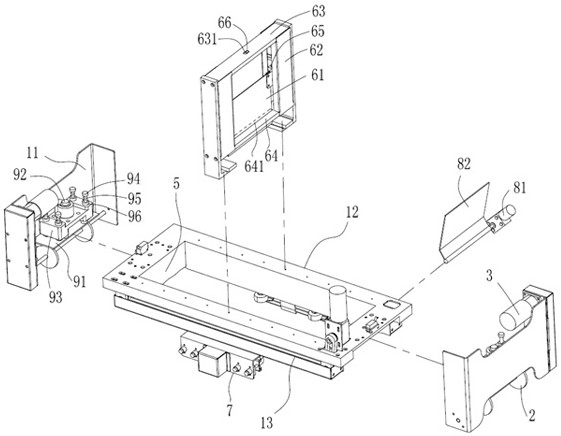

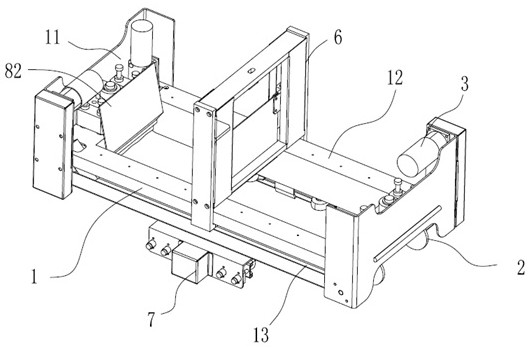

[0047] Such as figure 1 As shown, the present invention discloses an automatic plastering machine for the upper surface of wall tiles, which includes a frame 1, a traveling device 2, a driving device 3, a guiding device 7, a plastering part, a scraping device 6, a pulp moving mechanism 8 and a control system (not shown).

[0048] Such as figure 2 As shown, the frame in this embodiment adopts a split assembly type. The frame 1 includes two side supports 11 and a slurry mold frame 12 located in the middle, and the traveling device 2 and the driving device 3 are installed on the side supports 11 . The first vertical movement module 9 is installed on the side support 11 , the pulp mold frame 12 is installed on the first vertical movement module 9 , and the pulp mold frame 12 moves vertically under the control of the first vertical movement module 9 . The driving device 3 is connected with the running device 2 through a chain transmission mechanism 4 . The driving device 3 cont...

Embodiment 2

[0060] Such as Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that the frame 1 in this embodiment is an integrated frame, the two sides of the frame 1 are provided with installation grooves 14, and the running device 2 is arranged in the installation grooves 14 The running device 2 includes a wheel shaft 21 and road wheels 22 installed on both sides of the wheel shaft 21 . The driving device 3 is arranged above the installation slot 14 , and the driving device 3 is connected to the axle 21 through a chain transmission mechanism 4 .

[0061] combine Figure 11 ~ Figure 13 As shown, a second push rod 15 is fixed above the mounting groove 14. The shaft end of the second push rod 15 is connected to the wheel shaft 21 through a sleeve assembly. Two groups of bearings 23 are arranged on the wheel shaft 21. The sleeve assembly includes a sleeve Body 16 and cylinder cover 17, cylinder body 16 is arranged on the outside of chain transmission mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com