Shield cutter

A technology of shield cutters and shield cutterheads, which is applied in mining equipment, tunnels, earthwork drilling and mining, etc. It can solve the problems affecting the construction of mud-water shields and the consolidation of mud cakes in the central area, so as to prevent sedimentation and mud formation, Prevent sedimentation and solve the effect of mud cake consolidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the drawings and specific embodiments.

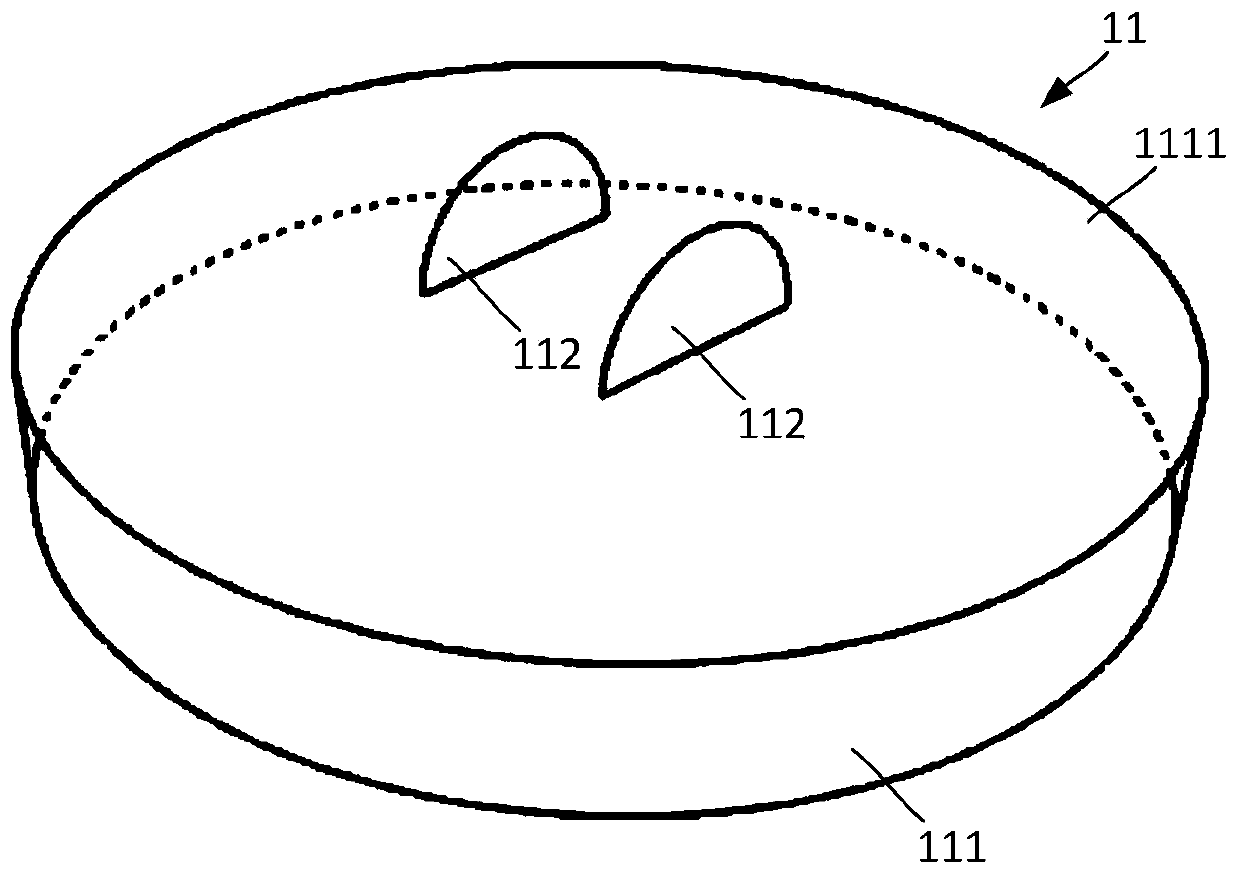

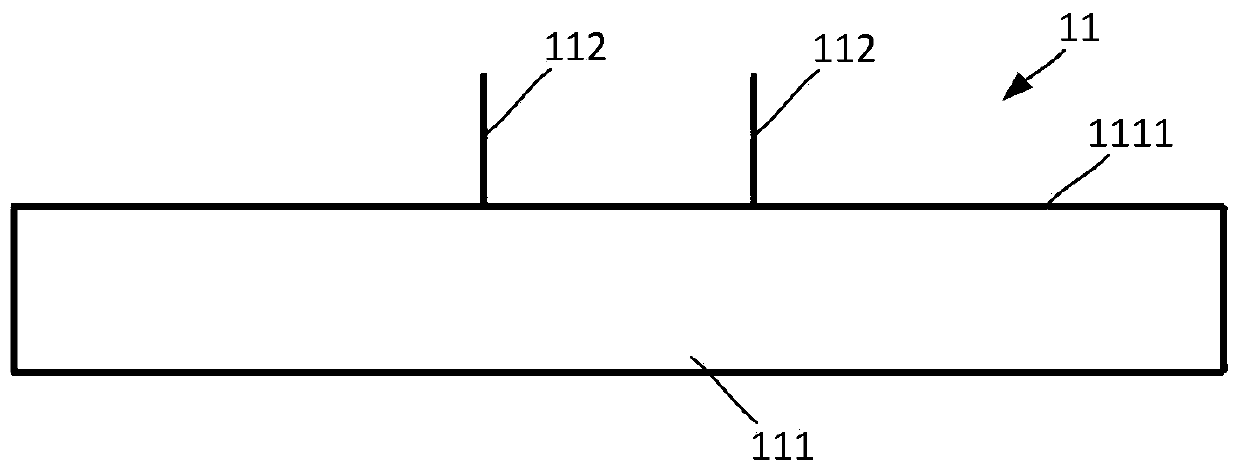

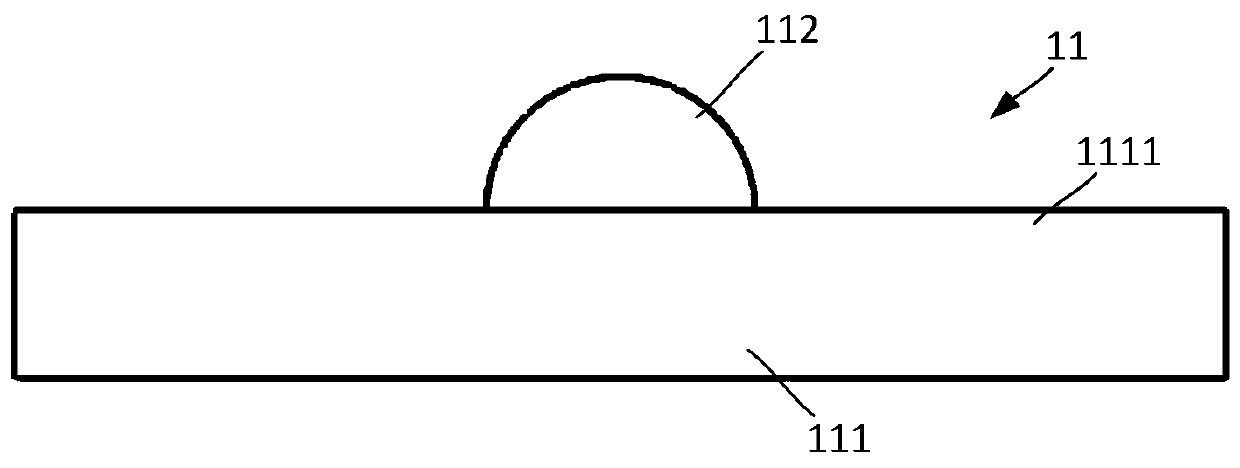

[0025] Refer to Figure 4 The present invention provides a shield cutter, which is used to solve the problem in the prior art that the hob is arranged in the center area of the cutter head to easily produce mud cake consolidation in the center area and affect the construction of the mud water shield. The shield cutter of the present invention is provided with a plurality of blades, and the blades are evenly arranged on the surface of the blade barrel around the center of the blade barrel, so that the blades are arranged in the form of fan blades of a turbine, and the blades are driven to rotate through the power structure In the process of rotation, the blade generates rotational force, which can transport the cut soil particles along the curve of the blade through the rotation force from the inside to the outside, and then transport the soil particles from t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com