A high-efficiency integrated excess sludge anaerobic digester

A technology of excess sludge and anaerobic digestion, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of poor resistance to organic load impact and poor liquid-solid mass transfer effect , inconvenient operation and maintenance, etc., to achieve the effect of preventing sludge deposition, compact structure and simple processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

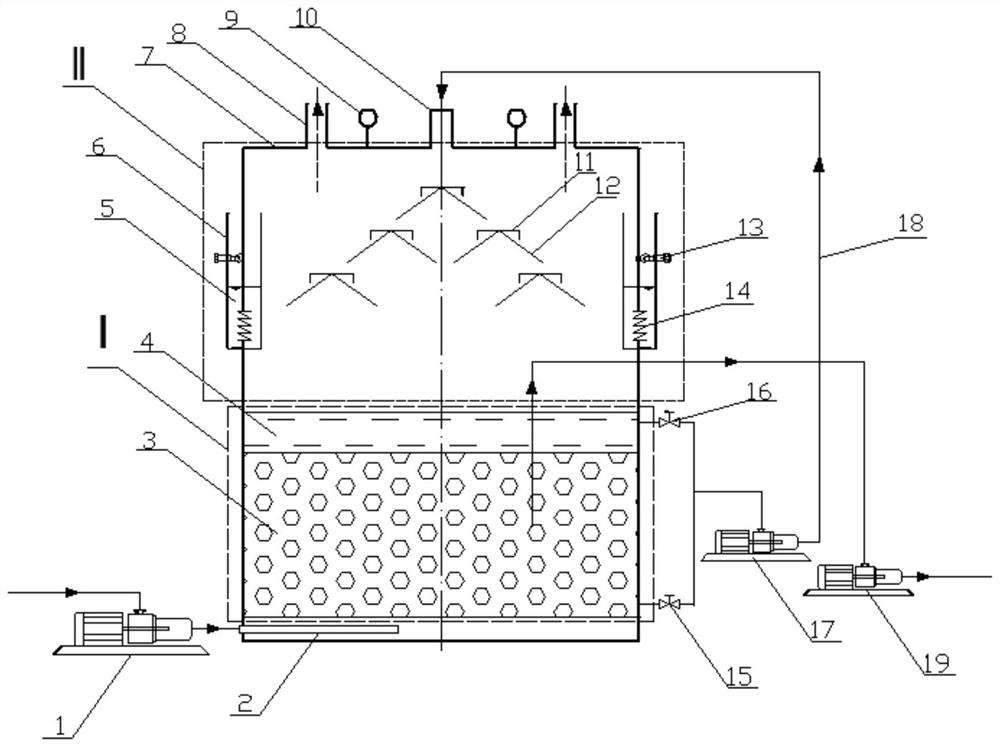

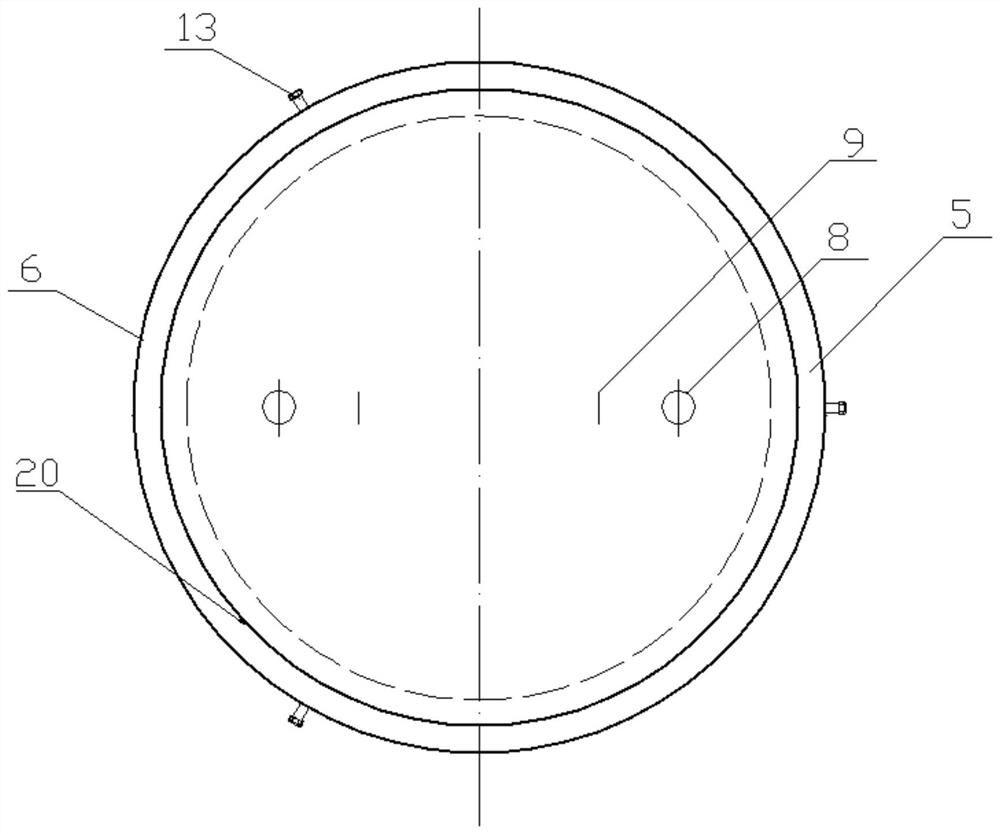

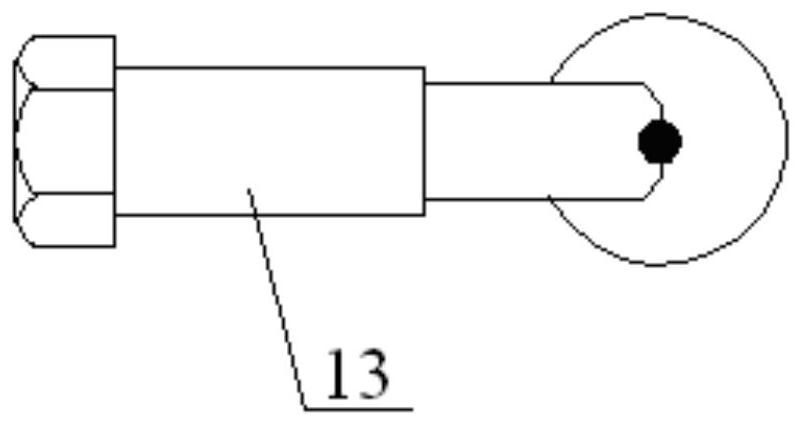

[0029] Such as Figure 1-3 As shown, a high-efficiency integrated excess sludge anaerobic digester provided by the present invention is characterized in that it includes a shell 20, and the top of the shell 20 is provided with a cover plate 7 extending downward around it; the inside and bottom of the shell 20 is a reaction module Ⅰ, the upper part is the gas storage module Ⅱ; the lower part of the reaction module Ⅰ is the sludge area 3, the upper part is the supernatant liquid area 4, and the bottom of the sludge area 3 is laid with a sludge inlet pipe 2, and the sludge passes through the external mud inlet screw pump 1 is connected to the mud inlet pipe 2; the supernatant liquid area 4 and the sludge area 3 are respectively connected to the supernatant liquid circulation pipe 16 and the sludge circulation inlet pipe 15, and after the two are connected in parallel, the sludge circulation is connected through the sludge circulation pump 17 The outlet pipe 18, the sludge circula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com