Motor truck scale weighing platform position detection and calibration device

A technology for detecting and calibrating a device and a weighing platform, applied in the field of truck scales, can solve problems such as low efficiency, time-consuming and labor-intensive, and achieve the effects of time-saving, labor-saving and high-efficiency adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

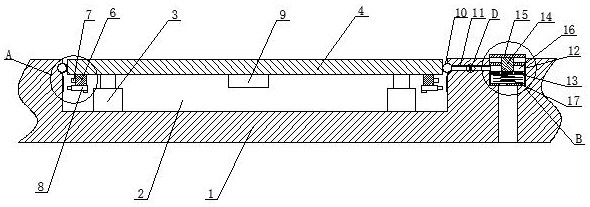

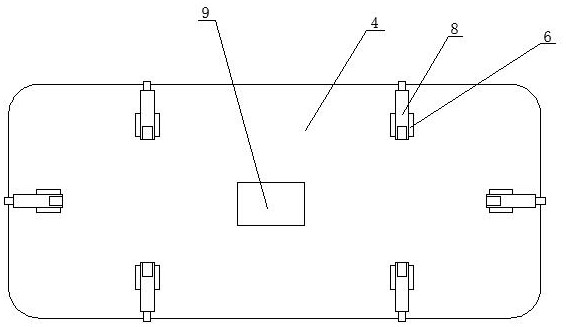

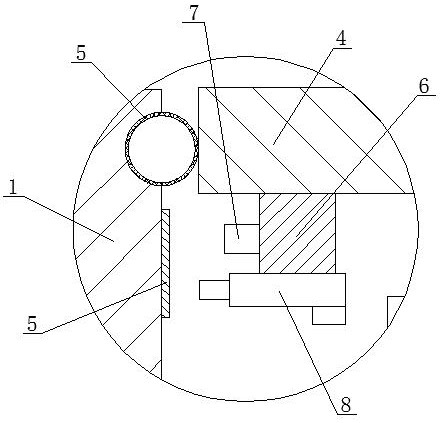

[0023] Such as Figure 1 to Figure 6 As shown, a vehicle scale weighing platform position detection and calibration device includes a base 1 , a weighing platform 4 , and a control device 9 . A foundation pit 2 is arranged on the base 1 , and a weighing platform 4 is arranged in the foundation pit 2 . The weighing platform 4 is in the shape of a rectangular plate. A load cell 3 is arranged between the weighing platform 4 and the bottom of the foundation pit 2 . A detection and calibration mechanism is provided on the circumference of the weighing platform 4 , and the detection and calibration mechanism includes a mounting seat 6 arranged around the weighing platform, a distance measuring device 7 and a distance calibration device 8 arranged on the mounting seat 6 . A reference plate 5 corresponding to the detection and calibration mechanism is provided on the side wall of the foundation pit 2 . The distance measuring device 7 is an infrared distance measuring sensor, and th...

Embodiment 2

[0027] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that in embodiment 2, the ranging device is a laser ranging sensor, and the rest of the structure is the same as that of embodiment 1.

Embodiment 3

[0028] Embodiment 3: The difference between Embodiment 3 and Embodiment 1 is that in Embodiment 3, the distance calibration device is a hydraulic cylinder, and other structures are the same as Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com