Slurry pipeline anti-blocking and automatic clogging clearing system and method

An automatic cleaning and mud pipeline technology, applied in the direction of cleaning methods and appliances, chemical instruments and methods, pipe components, etc., can solve the problems of untimely flushing of pipelines, large impact of unit operation, pipeline silting and other problems, and achieve easy silting cleaning , good orientation, strong penetrating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

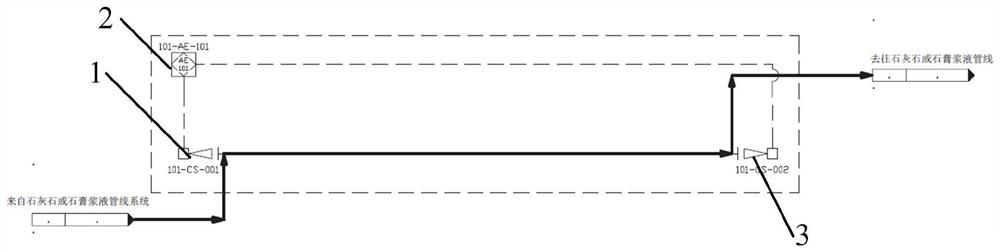

Embodiment 1

[0018] Embodiment 1 of the present invention: a system for anti-blocking and silting automatic cleaning of slurry pipelines, comprising a first dual-frequency ultrasonic generator 1 and a first ultrasonic receiver 3; the first dual-frequency ultrasonic generator 1 is arranged at the bottom of the mud pipeline Upstream, the first dual-frequency ultrasonic generator 1 is electrically connected to the data processor 2, and the first dual-frequency ultrasonic generator 1 is used to send ultrasonic waves. When the first dual-frequency ultrasonic generator 1 and the first ultrasonic receiver 3 When the mud pipeline is blocked, the ultrasonic waves emitted by the first dual-frequency ultrasonic generator 1 are reflected by the blockage, and the ultrasonic waves received by the first ultrasonic receiver 3 are weakened or disappeared. 2. A slurry pipeline anti-blocking and silting automatic cleaning system according to claim 1, the first dual-frequency ultrasonic generator 1 and the fir...

Embodiment 2

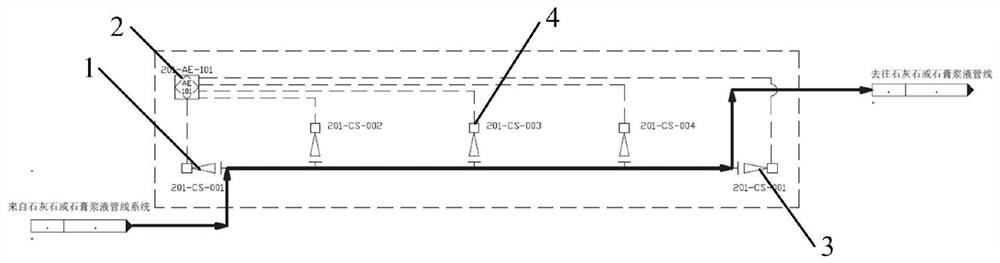

[0021] Embodiment 2: A slurry pipeline anti-blocking and silting automatic cleaning system, including a first dual-frequency ultrasonic generator 1 and a first ultrasonic receiver 3; the first dual-frequency ultrasonic generator 1 is arranged upstream of the mud pipeline, and the first A dual-frequency ultrasonic generator 1 is electrically connected to the data processor 2, and the first dual-frequency ultrasonic generator 1 is used to emit ultrasonic waves. When the mud pipeline between the first dual-frequency ultrasonic generator 1 and the first ultrasonic receiver 3 generates When silting occurs, the ultrasonic waves emitted by the first dual-frequency ultrasonic generator 1 are reflected by the silting, and the ultrasonic waves received by the first ultrasonic receiver 3 weaken or disappear. Both the first dual-frequency ultrasonic generator 1 and the first ultrasonic receiver 3 are arranged at the elbow or tee of the mud pipeline. The mud pipeline between the first dual...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com