A dual-spindle core-moving CNC lathe

A CNC lathe and dual-spindle technology, applied in the field of lathes, can solve the problems of increasing friction, accumulating between the two workpiece spindles and the turning tools at both ends, squeezing and jamming, etc., and achieving the effect of preventing tool collision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

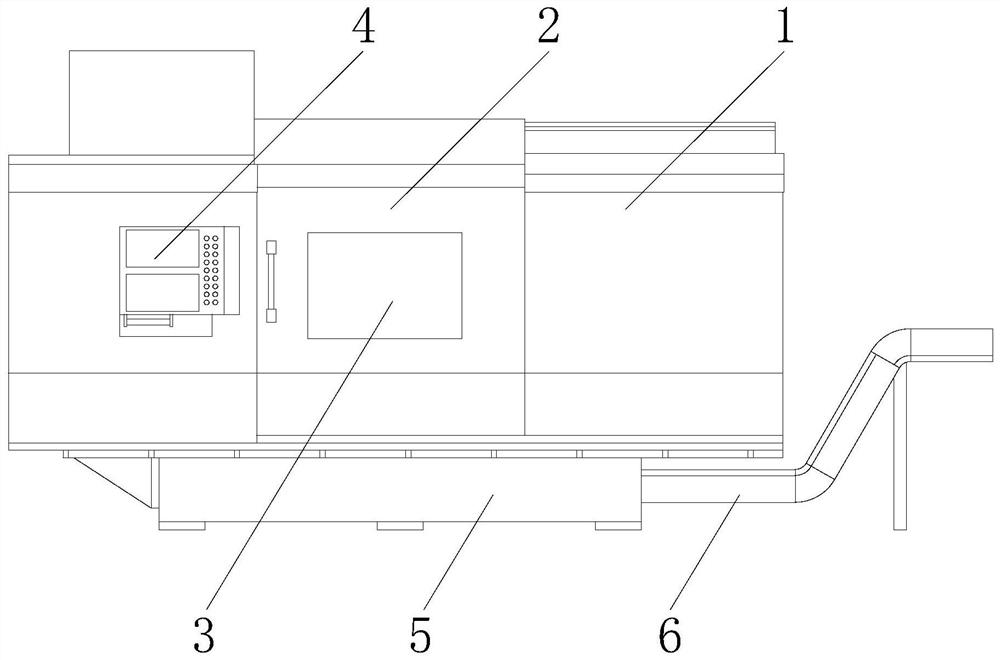

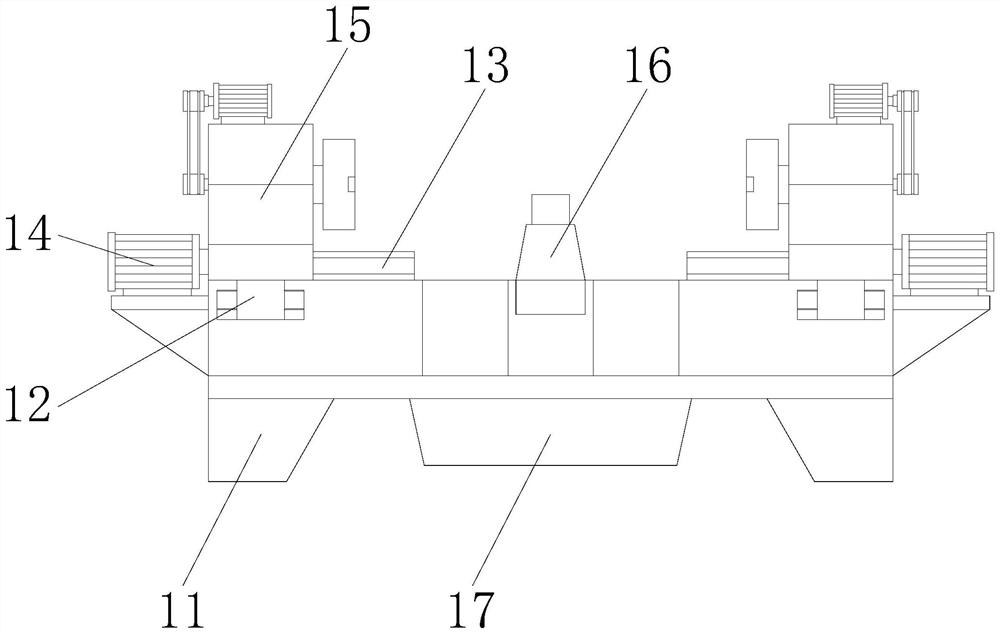

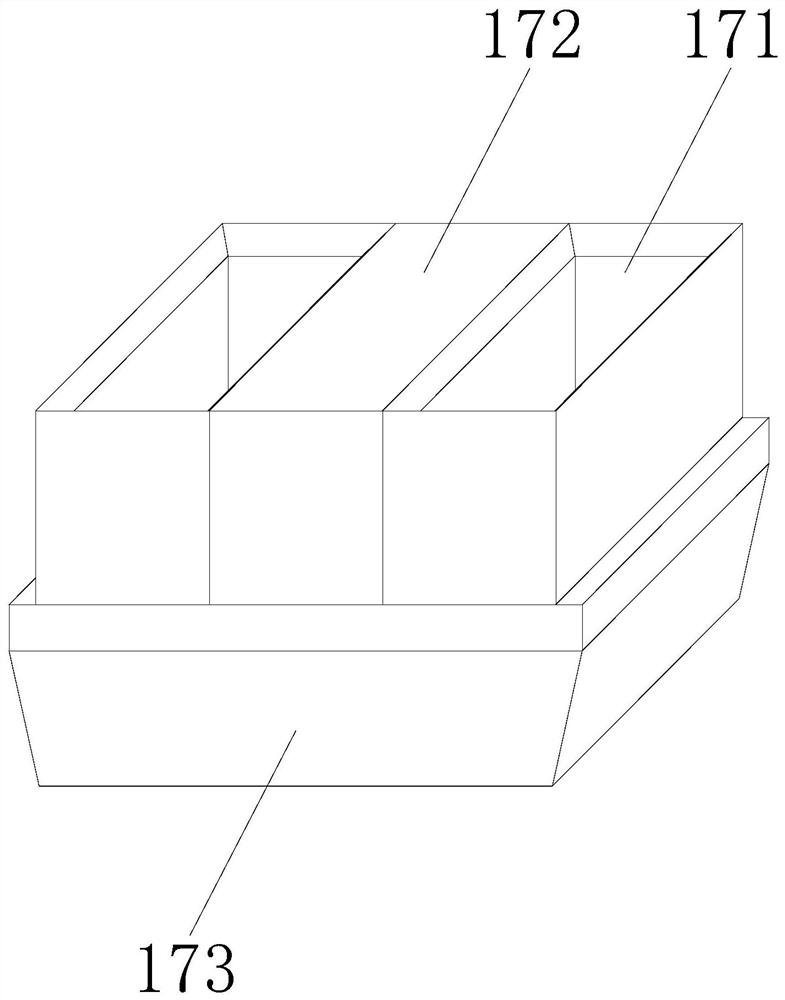

[0026] as attached figure 1 to attach Figure 6 Shown:

[0027] The present invention is a dual-spindle core-moving CNC lathe, the structure of which includes a lathe main machine 1, a movable door 2, a window 3, a control panel 4, a fixed base 5, and a chip removal pipe 6. The front end of the lathe main machine 1 is provided with a movable door 2 , and the front surface of the movable door 2 is embedded with a window 3, the control panel 4 is fixedly installed on the left end of the front surface of the lathe host 1, the bottom of the lathe host 1 is fixed to the fixed base 5, and the lower end of the lathe host 1 is connected to the chip discharge pipe The lathe host 1 includes a supporting frame 11, a mover 12, a slide rail 13, a motor 14, a workpiece clamping device 15, a tool clamping head 16, and a chip guide mechanism 17. The upper end of the supporting frame 11 is provided with a There is a mover 12, and the upper end of the mover 12 is fixed to the bottom of the sl...

Embodiment 2

[0035] as attached Figure 7 to attach Figure 9 Shown:

[0036] Wherein, the blocking mechanism 72d includes a supporting bottom plate d1, a shielding horizontal plate d2, and an opening and closing mechanism d3. The supporting bottom plate d1 is fixedly installed on the inner bottom surface of the fixed frame 72a, and the outer side of the supporting bottom plate d1 is welded to the bottom of the shielding horizontal plate d2. , the inner side of the shielding horizontal plate d2 is hinged to the lower end of the opening and closing mechanism d3, the bottom of the opening and closing mechanism d3 is in conflict with the upper surface of the supporting base plate d1, there are eighteen shielding horizontal plates d2, and the opening and closing mechanism d3 is set There are fourteen, and nine shielding horizontal plates d2 and seven opening and closing mechanisms d3 form a group, and an opening and closing mechanism d3 is arranged between every two shielding horizontal plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com