Real-time monitoring method for grouting construction compactness of steel bar sleeve

A steel sleeve, real-time monitoring technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of internal non-compact, difficult to fill grouting channels, etc., to achieve real and effective data, ensure grouting density, improve The effect of monitoring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

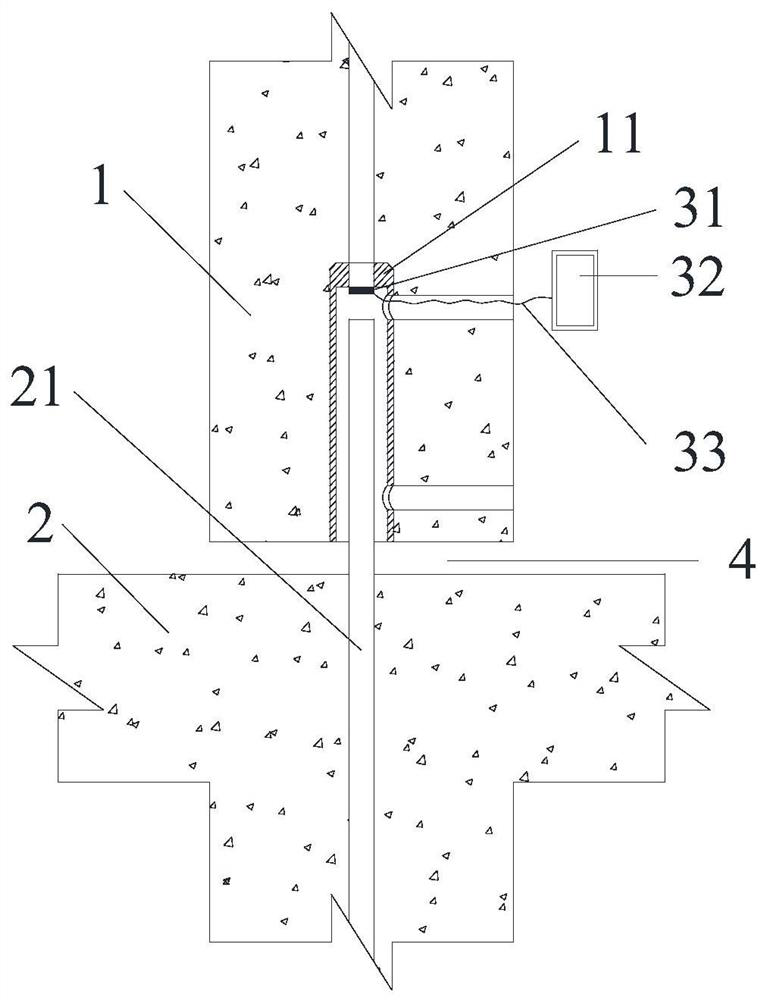

[0031] Such as figure 1 As shown, the method for real-time monitoring of the density of steel sleeve grouting construction includes the following steps:

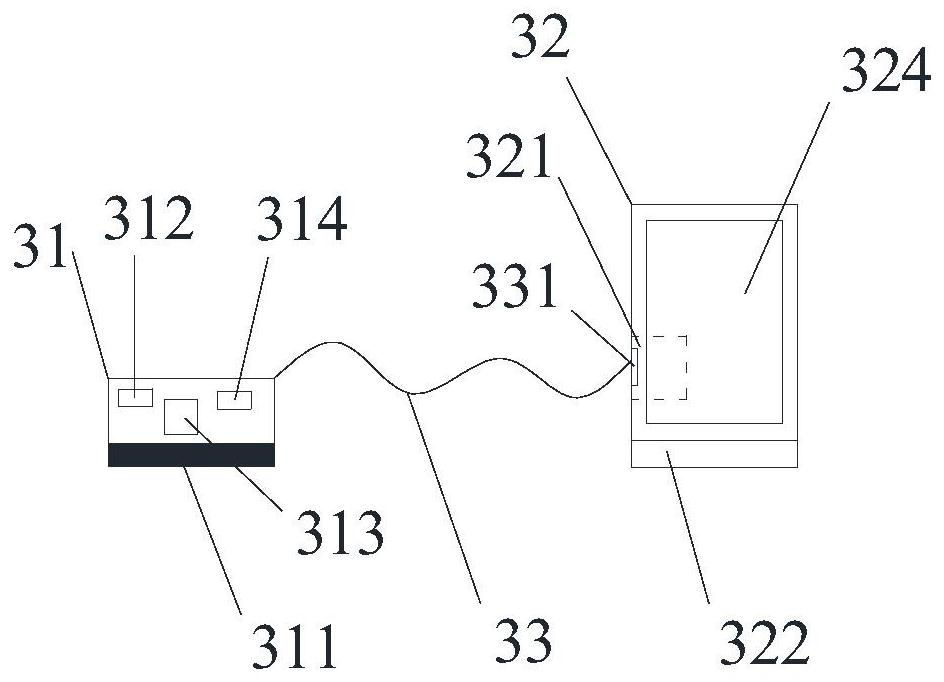

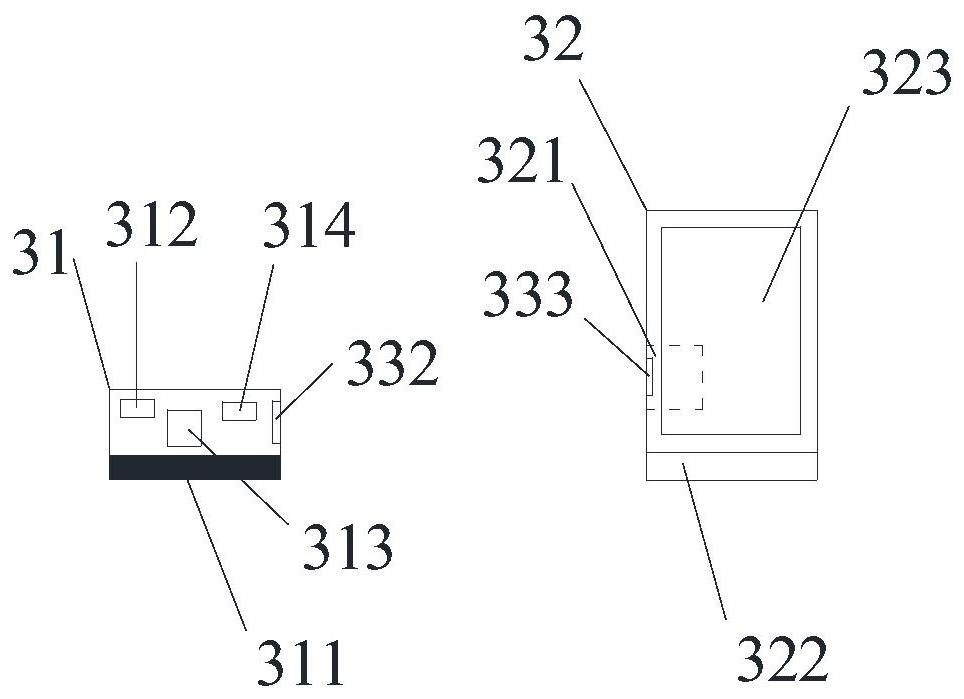

[0032] S1. Fix the density monitoring sensor on the top of the grouting sleeve: after adjusting the position of the sleeve rib 21 and the anchoring length to meet the design requirements, the prefabricated component 1 with the grouting sleeve 11 is hoisted to the upper surface of the underlying structure 2 Stop statically after 50cm of the working surface, fix several compactness monitoring sensors 31 on the inner top of the grouting sleeve 11, connect the sensor 31 to the data line 33 of the monitor 32 from the grout outlet, and then continue the prefabricated component 1 Hoist to the designated position and fix it effectively;

[0033] S2, sealing the grouting communication chamber 4;

[0034] S3. After the plugging structure of the connecting cavity 4 meets the grouting requirements, carry out the grouting construction ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com