An automatic testing device for the stiffness of synthetic fabrics for rubberized shoe uppers

An automatic detection and fabric stiffness technology, applied in the direction of measuring devices, strength characteristics, and test material hardness, can solve problems such as equipment not meeting actual needs, and achieve the effects of unified product quality standards, accurate data, and high equipment sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings. The description in this part is only exemplary and explanatory, and should not have any limiting effect on the protection scope of the present invention. .

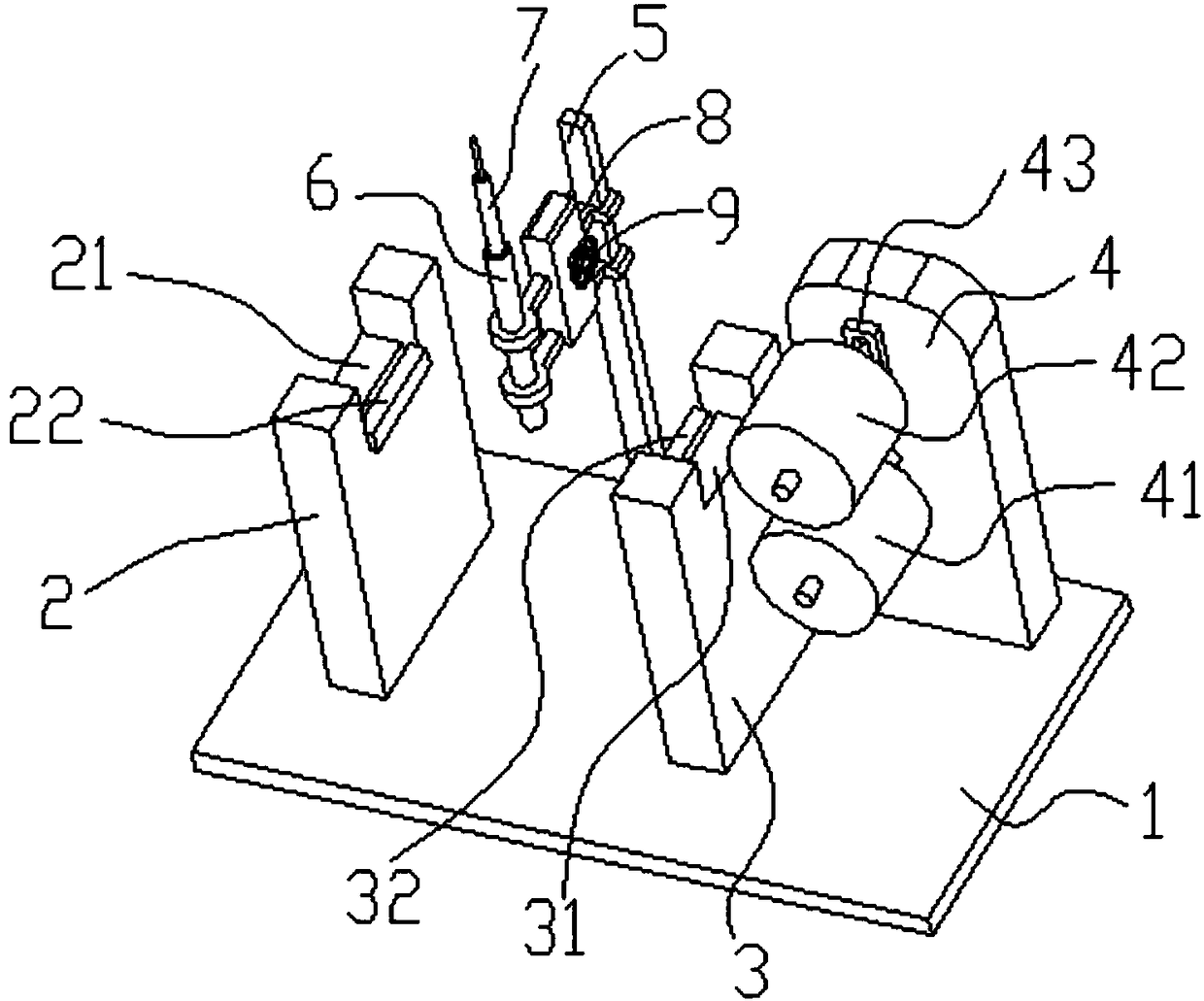

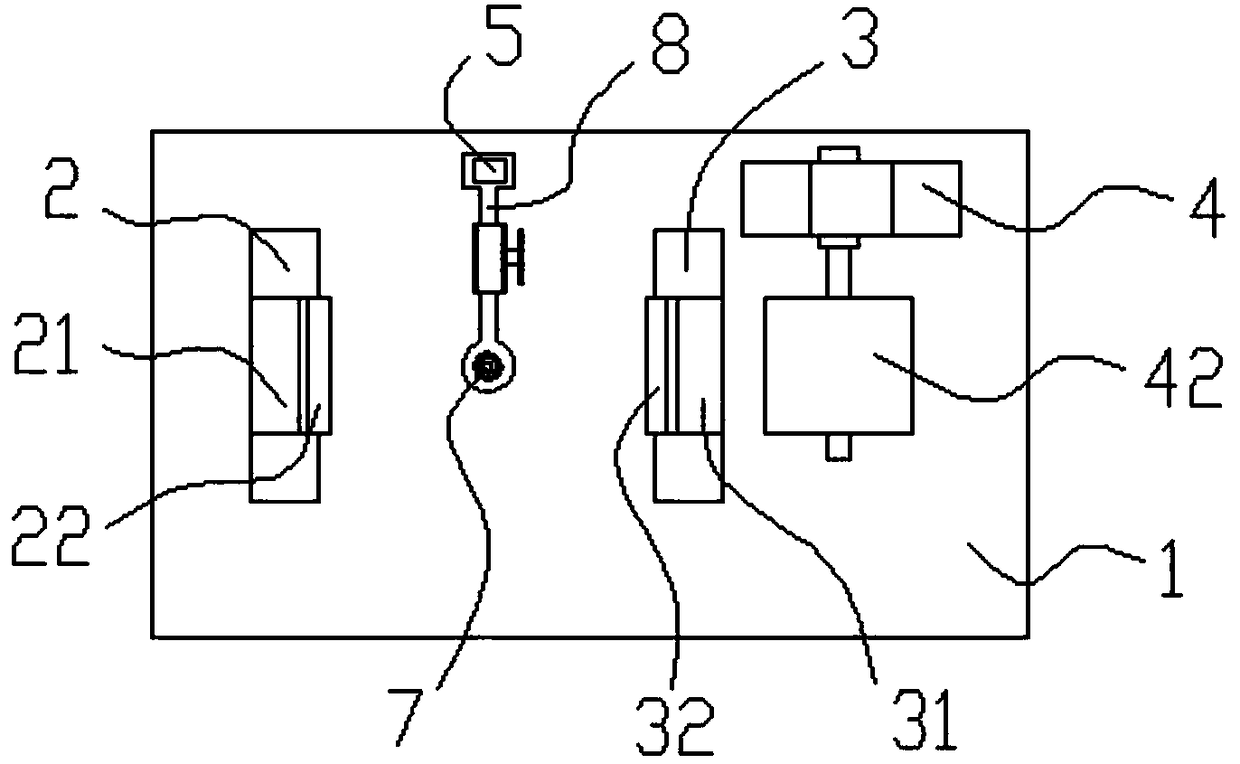

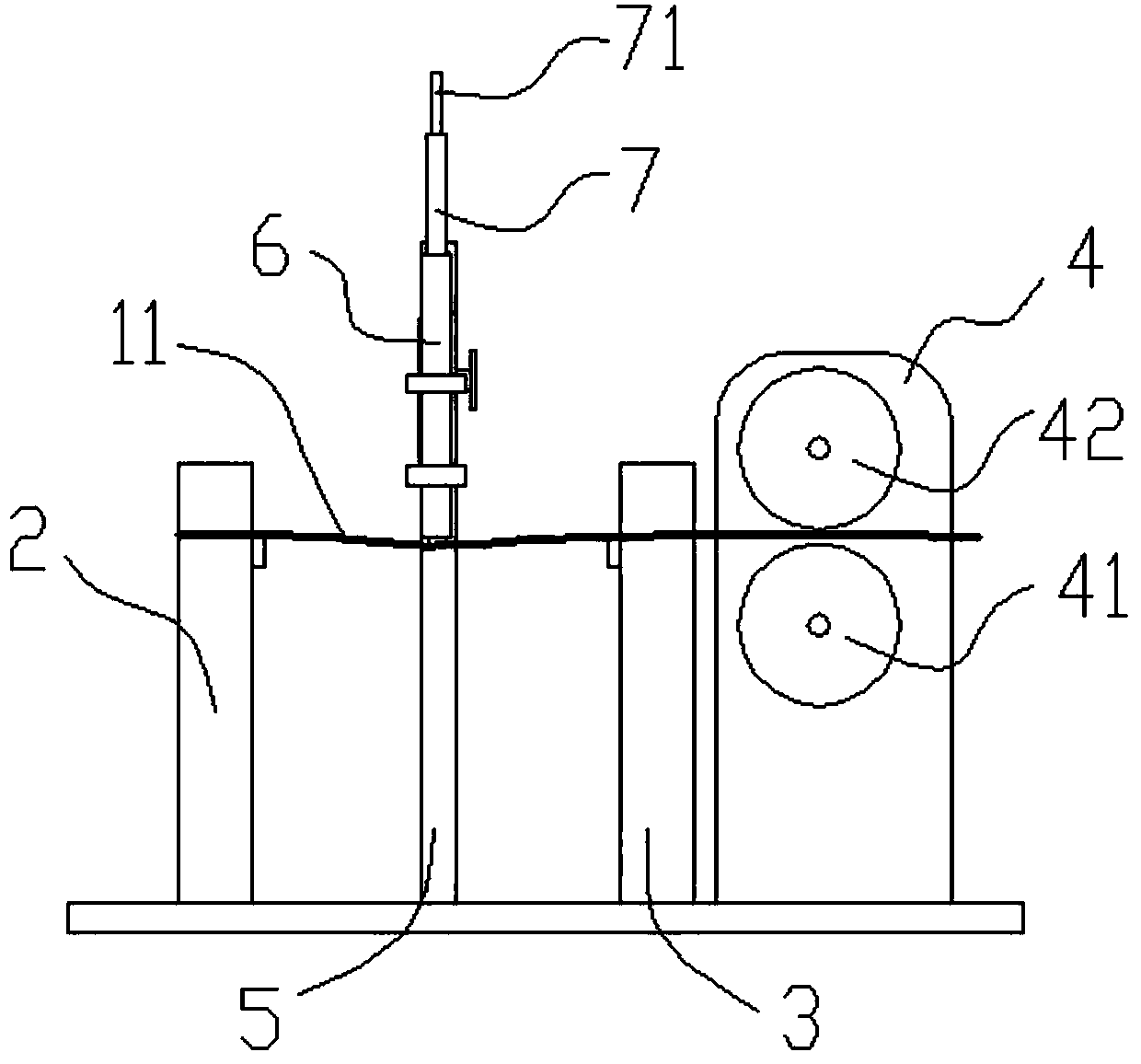

[0032] Such as Figure 1-Figure 4 As shown, the specific structure of the present invention is: an automatic detection device for the stiffness of the synthetic cloth of rubber cloth shoe uppers, which includes a base 1, on which an inlet bracket 2 and an outlet bracket 3 are arranged in parallel at intervals, and on the inlet bracket 2 is provided with an infrared emitter 22, and correspondingly an infrared receiver 32 is provided on the outlet bracket 3; a force applying sleeve 6 is arranged at the middle position above the connection line of the inlet bracket 2 and the outlet bracket 3 and a can be ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com