Refrigerator door body based on modularization

A refrigerator door body and modularization technology, which is applied to household refrigerators, coolers, lighting and heating equipment, etc., can solve the unfavorable refrigerator production efficiency, increase the number and types of parts, increase the cost of parts molds and foaming molds, etc. problems, achieve high market application value, reduce production costs, and facilitate installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

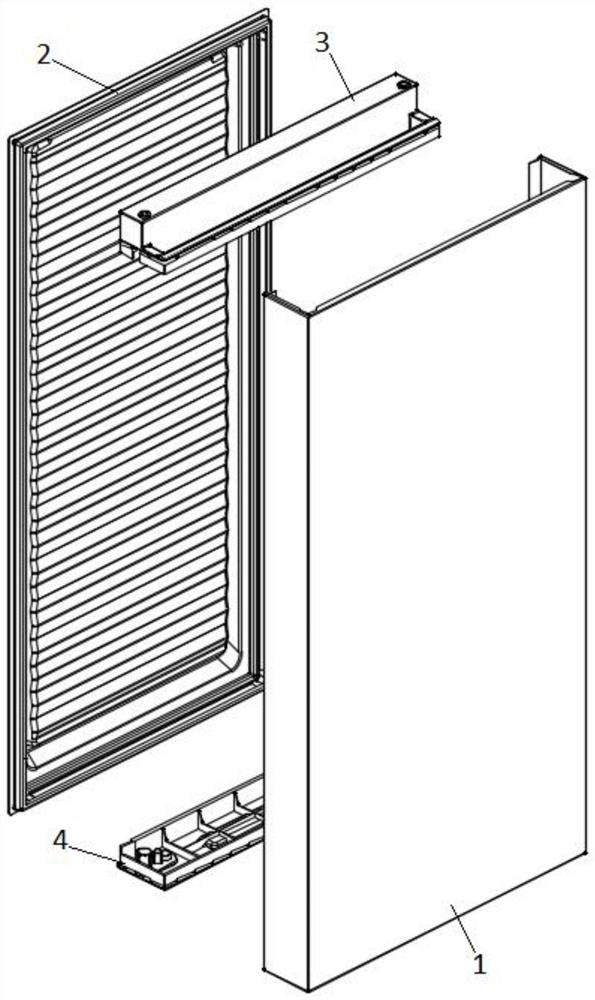

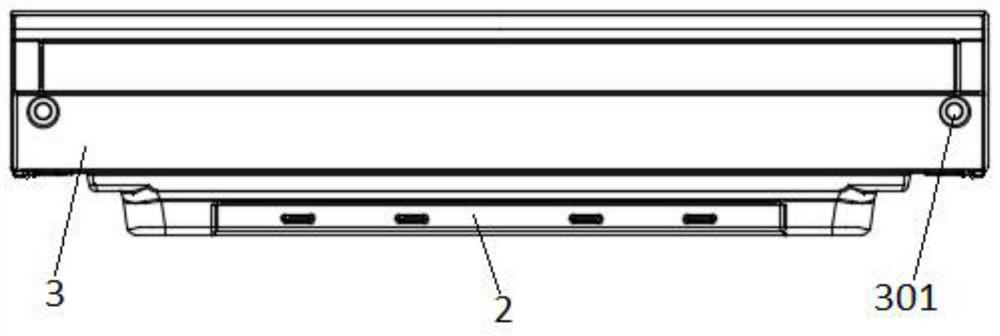

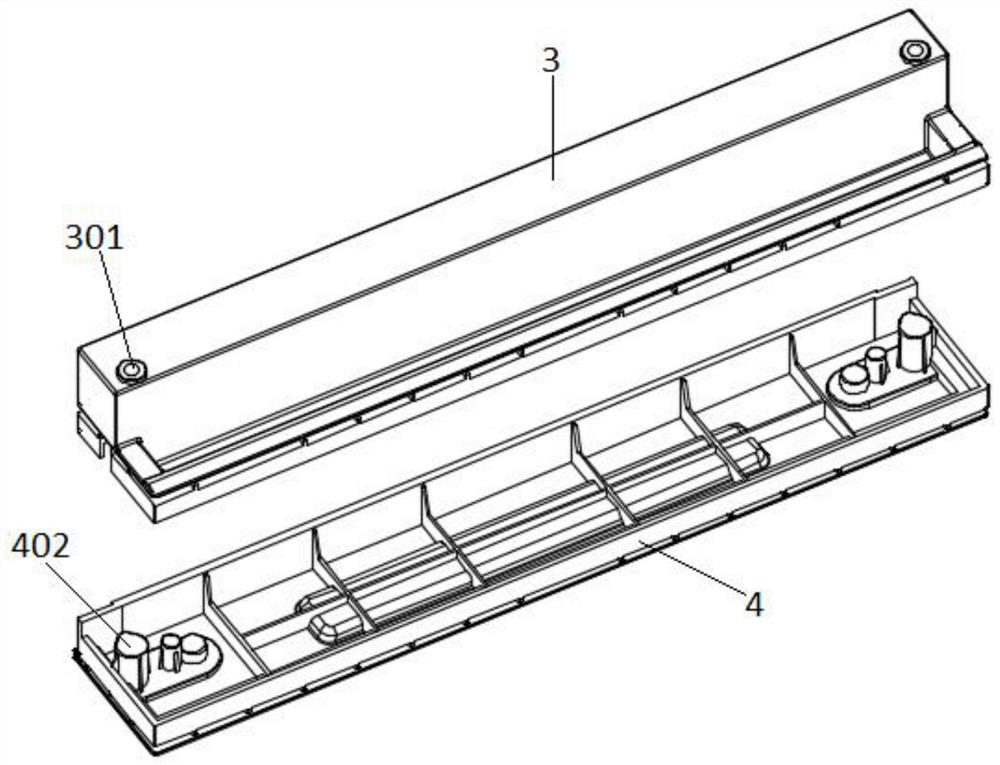

[0023] see Figure 1-4 As shown, the present invention is a refrigerator door based on modularization, including a door shell 1 and a door lining 2 arranged side by side; an upper decorative strip 3 and a lower decorative strip 4 are arranged between the door shell 1 and the door lining 2 The upper decorative strip 3 and the lower decorative strip 4 are respectively arranged on the upper and lower ends of the door shell 1; a gap for filling foam material is formed between the door shell 1, the door lining 2, the upper decorative strip 3 and the lower decorative strip 4 accommodating chamber;

[0024] The two ends of the upper decorative strip 3 are symmetrically provided with a pair of first connection concave holes 301 for the installation of the refrigerator door hinge; the upper decorative strip 3 has a handle structure, and the handle structure is a built-in structure at this time; A pair of mounting grooves 401 are arranged symmetrically at the ends; a surface of the mou...

specific Embodiment 2

[0030] The handle structure is a convex structure, and the handle structure is arranged on the lower decorative strip 4 at this time.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com