A high-precision motor closed-loop test device

A test device and motor closed-loop technology, applied in the direction of electrical testing/monitoring, etc., can solve the problems of high precision requirements, easy damage, and difficult leveling of the support plate, and achieve the effect of universality.

Active Publication Date: 2013-10-16

中国航天科技集团公司第一研究院第十八研究所

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

It shows that this double support plan has difficulty in leveling and requires high accuracy of support plates. After deformation and stress, the process displacement sensor

Easy to damage and other issues

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

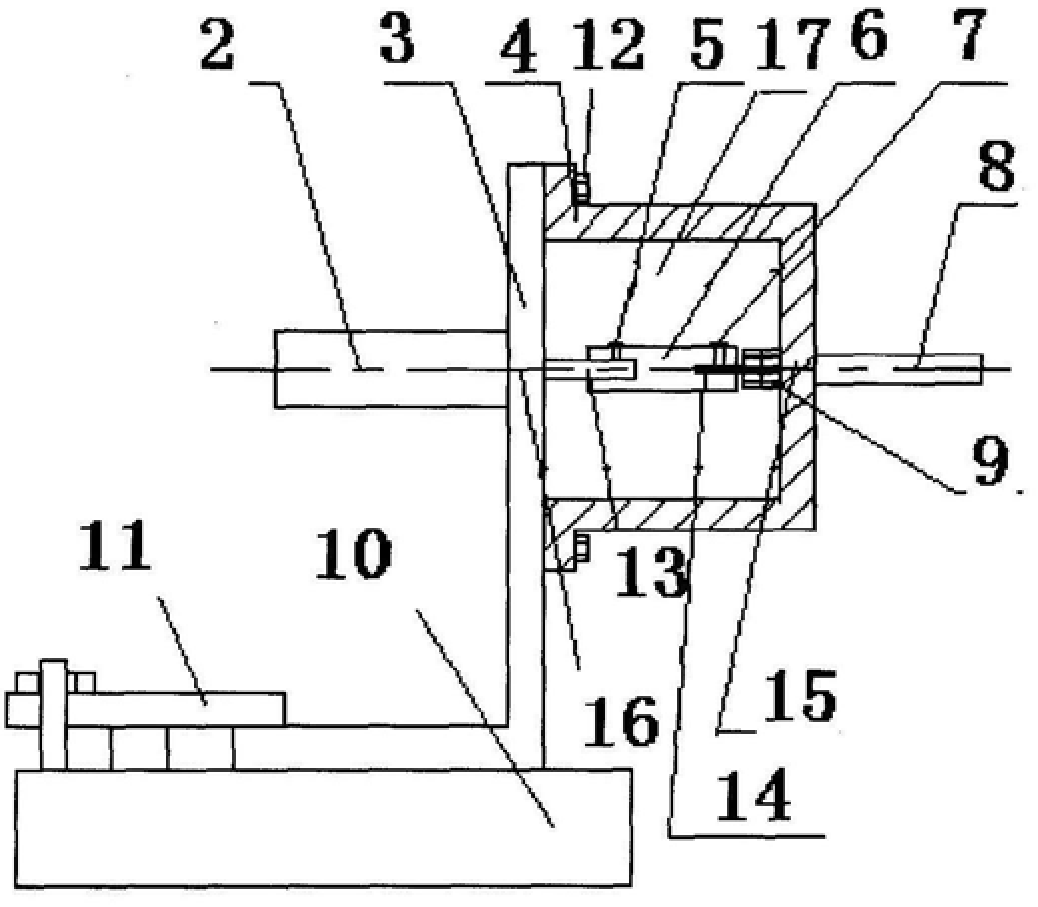

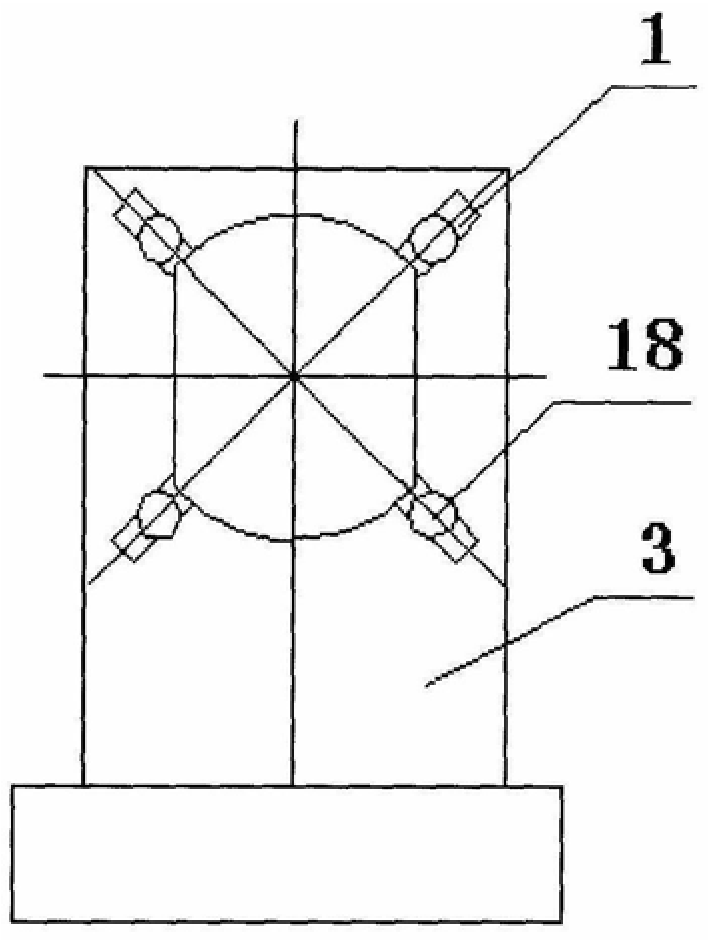

[0017] The four chutes 1 of the fixed motor 2 on the fixed support plate 3 are U-shaped grooves.

[0018] The supporting shell 4 has a transparent window 17.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to the field of motor closed-loop test, in particular to a high-precision motor closed-loop test device used in the motor performance debugging stage. It includes a motor, a fixed support plate, a front locking screw, a flexible coupling, a rear locking screw, a displacement sensor, a slide rail, and a pressing plate. The high-precision motor closed-loop test tooling adopts a single support plate integrated with the displacement sensor support shell, which ensures the coaxial accuracy of the assembly. A window is opened on the side of the support shell to ensure the installation space; the double nuts are tightened to prevent the displacement sensor from rolling during high-speed rotation, ensuring the rigidity of the displacement sensor and the support shell; the chute on the support shell can ensure the installation of different types of motors , to achieve the versatility of closed-loop experimental device design.

Description

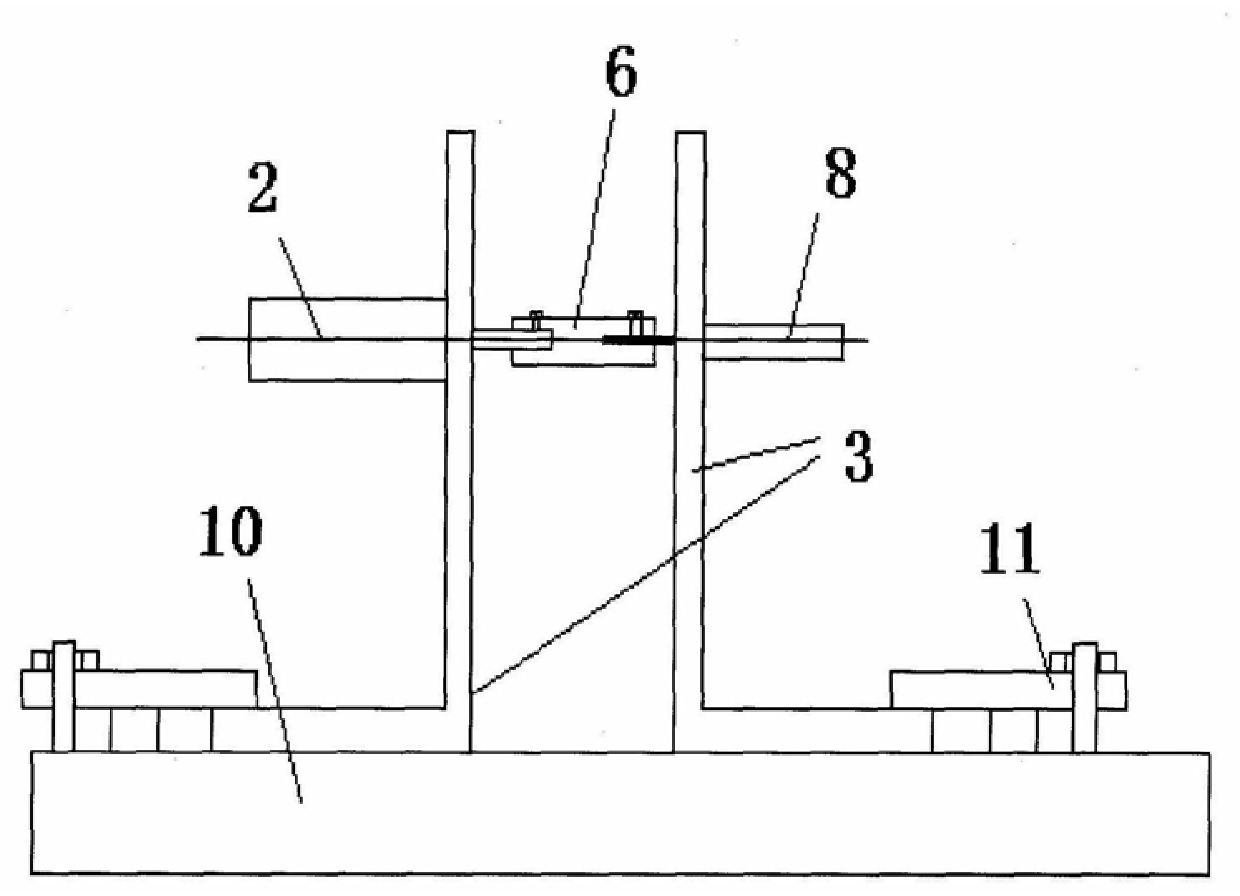

A high-precision motor closed-loop test device Technical field The present invention relates to the field of motor closed-loop test, be specifically related to a kind of high-precision motor used for motor performance debugging stage Machine closed-loop test device. Background technique Motor is the important composition stand-alone of electromechanical actuator, all will carry out self's own before delivery whole assembly test Characteristic test. Among them, the closed-loop characteristic test is one of the more important ones, and its performance also directly affects the follow-up unit. machine product debugging. At present, for the closed-loop characteristic test of the motor, more double-plate symmetrical support devices are adopted to realize, as shown in Figure 1 It shows that this double-support plan has difficulty in leveling and requires high precision of the support. After deformation and stress, the process displacement sensor Easy to damage and other...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G05B23/02

Inventor 郑继贵郑再平

Owner 中国航天科技集团公司第一研究院第十八研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com