Test pipe fitting axial pretreatment operation platform

A technology for operating platforms and test tubes, applied in workshop equipment, manufacturing tools, etc., can solve difficult problems such as no reference starting point and end point for test tube fittings, and achieve the effect of fast work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

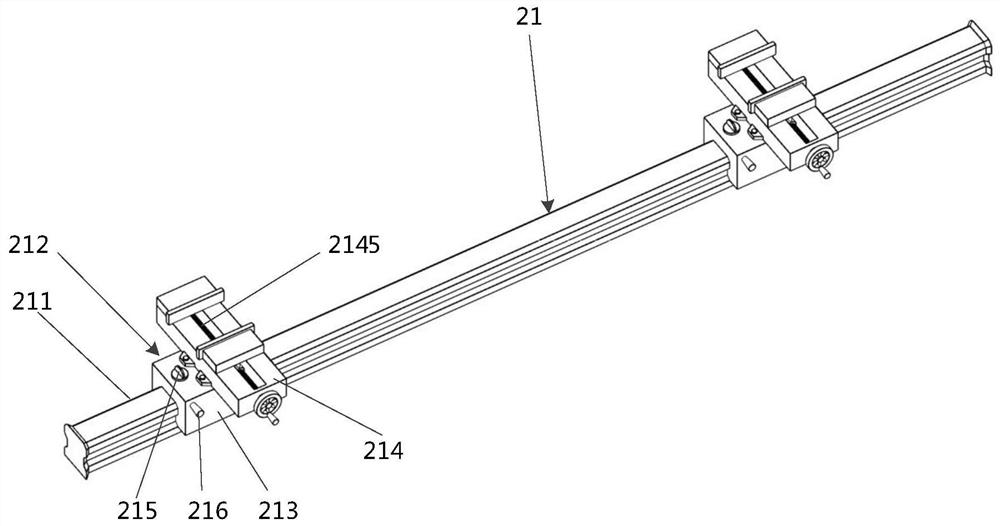

[0017] The specific structure and implementation process of this solution will be described in detail below through specific embodiments and accompanying drawings. It should be noted that all the screw locks in the present invention have the same structure, therefore, after the structure of one of the screw locks is described in detail, it will not be described one by one in the following.

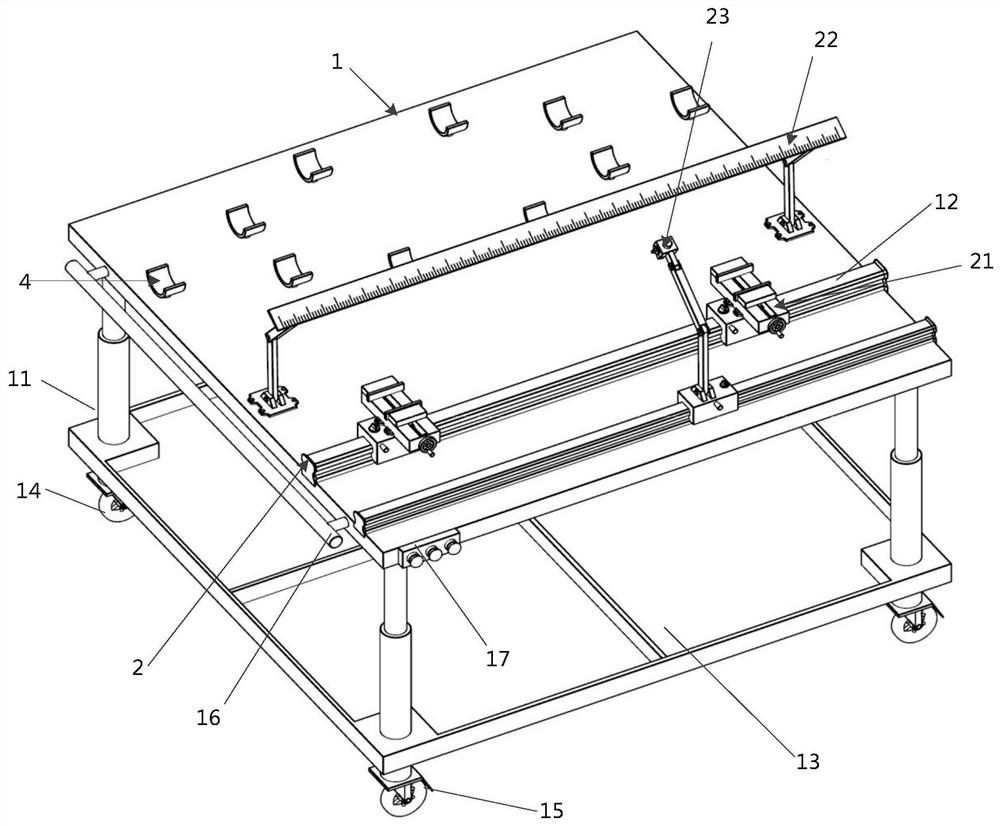

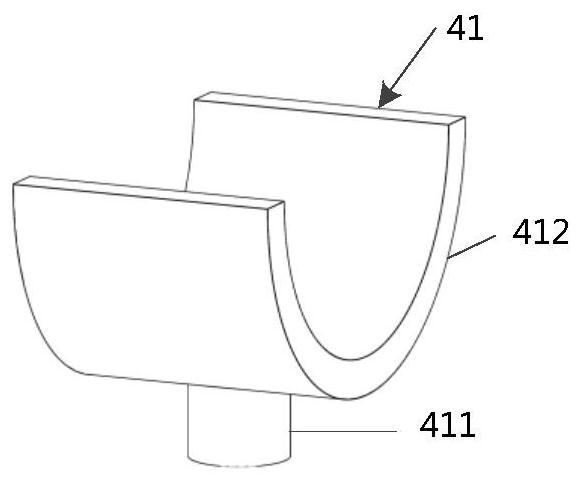

[0018] Such as figure 1 As shown, in one embodiment of the present invention, an operation platform for axial pretreatment of test pipes is disclosed, which includes a work frame 1 , an axial surveying device 2 and a temporary storage device 4 .

[0019] The working frame 1 is used to provide drawing space for test pipe fittings, including a frame composed of four support frames 11, and a table 12 and a shelving table 13 fixed on the support frames 11 at intervals up and down; the table 12 is used to install corresponding drawing devices, And the shelving table 13 can be used to place var...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com