Diesel engine flywheel casing seam allowance and end surface shape and position tolerance detection method

A diesel engine, shape and position tolerance technology, applied to mechanical measuring devices, measuring devices, mechanical devices, etc., can solve problems such as shape and position tolerances, and achieve the effects of reducing measurement errors, effective detection results, and small measurement errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

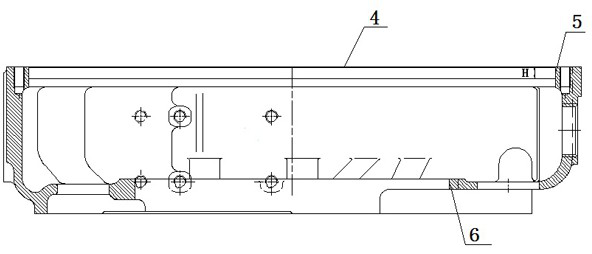

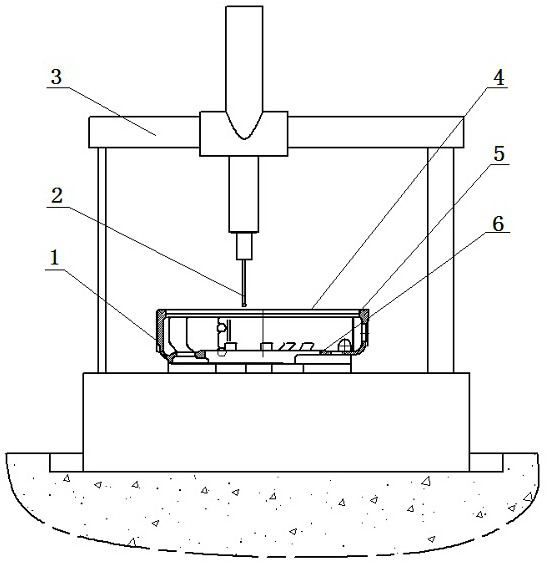

Image

Examples

Embodiment

[0044] Using the detection method of the present application to measure 8 flywheel housings, the detection results are as follows:

[0045]

[0046]

[0047] It can be seen from the above table that the runout of the end of the large spigot to the reference circle is within the range of 0.017-0.021; Within the range of 0.20, the test results are basically consistent and meet the design requirements.

[0048] In summary, the present invention adjusts the workpiece measurement benchmark, increases the accuracy of the simulated circular motion of the measuring point, and measures the behavior tolerance of the flywheel housing circular runout, which is accurate and effective. The consistency of the measurement results is good, the measurement error is small, and the detection accuracy and accuracy Higher, it can provide effective detection results, and is suitable for the detection of shape and position tolerances such as coaxiality and circular runout of shafts or hole part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com